Automobile brake-by-wire system and brake control method and device

A brake-by-wire and braking control technology, applied in the automotive field, can solve the problems of poor braking stability and slow braking response speed, and achieve the effect of high braking stability and fast braking response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

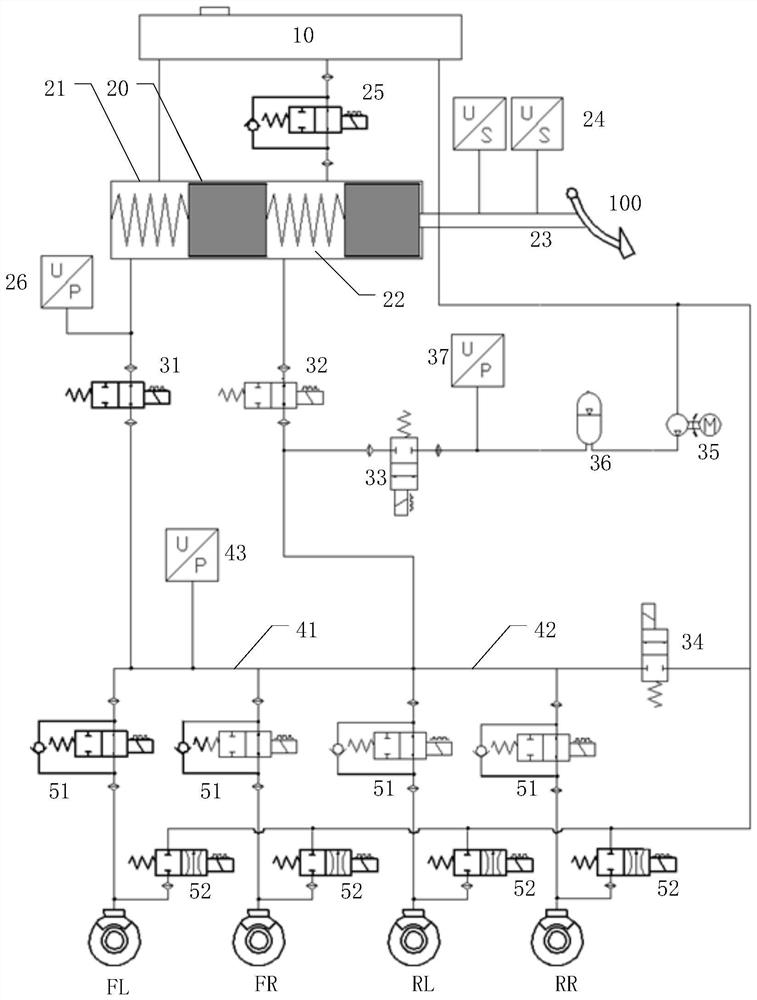

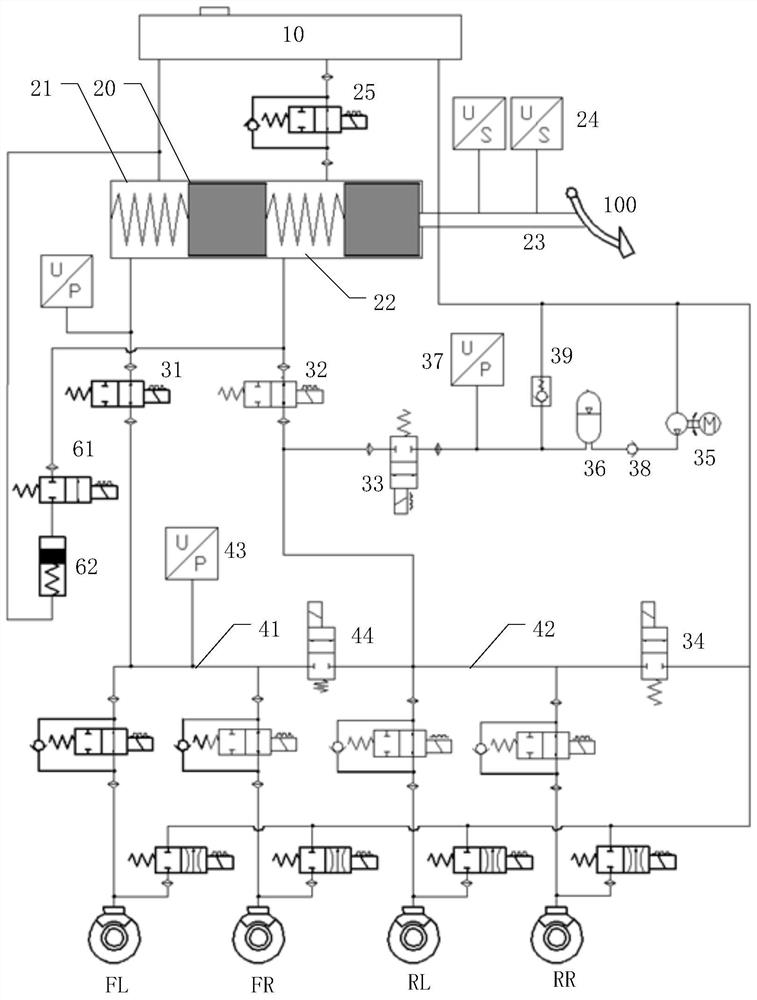

[0043] figure 1 It is a schematic diagram of an automobile brake-by-wire system according to an embodiment of the present application.

[0044] refer to figure 1 As shown, the brake-by-wire system provided in this embodiment includes a liquid storage pot 10, a master cylinder 20, a displacement sensor 24, a first normally open isolation valve 31, a second normally open isolation valve 32, a linear boost valve 33, an energy storage device 36 , pressure generating device 35 , front main wheel cylinder 41 , rear main wheel cylinder 42 and linear pressure reducing valve 34 .

[0045] The liquid storage pot is used to store brake fluid, which is the working medium of the brake system and used to transmit pressure, feedback torque, etc. The liquid storage pot is provided with a plurality of liquid inlets and liquid outlets for completing the circulation of the brake fluid in the system.

[0046] The master cylinder 20 includes a chamber 21 and a chamber 22. The master cylinder 20...

Embodiment 2

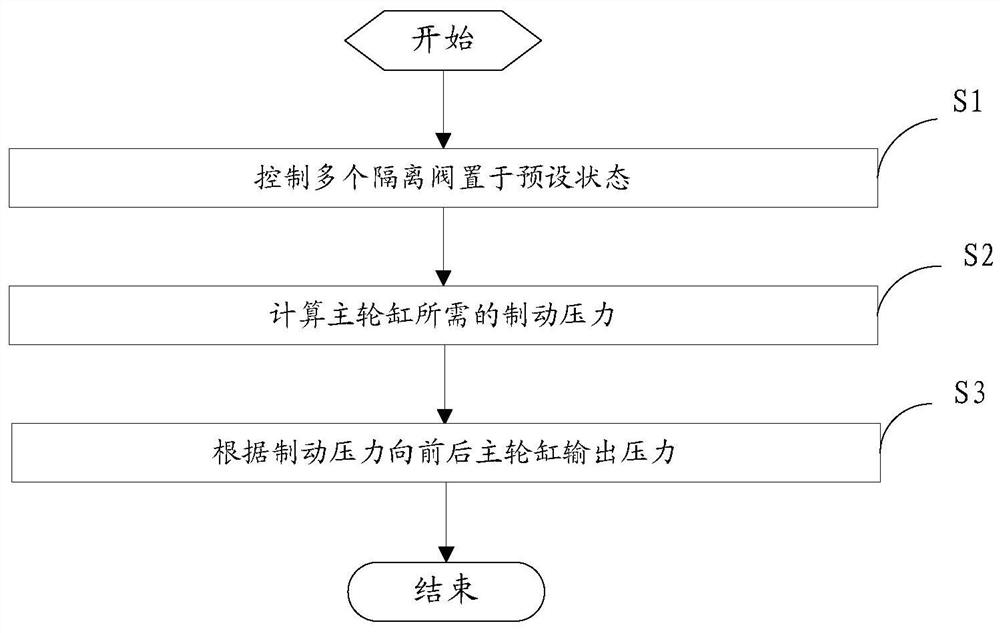

[0064] image 3 It is a flow chart of a braking control method according to an embodiment of the present application.

[0065] Such as image 3 As shown, the brake control method provided in this embodiment is applied to the brake-by-wire brake system provided in the previous embodiment, and the brake control method includes the following steps:

[0066] S1. Controlling multiple isolation valves to be in a preset state.

[0067] That is, when the car is normally powered on and started, the first normally open isolation valve and the second normally open isolation valve are controlled to close, and the front and rear isolation valves are controlled to be turned on. In this way, the pressure generated by the pressure generating device can enter the corresponding main wheel cylinder through the accumulator, and finally enter the supporting wheel cylinder to realize braking.

[0068] S2. Calculating the braking pressure required by the main wheel cylinder.

[0069] That is, th...

Embodiment 3

[0077] Figure 5 It is a block diagram of a braking control device according to an embodiment of the present application.

[0078] Such as Figure 5 As shown, the brake control device provided in this embodiment is applied to the brake-by-wire brake system provided in Embodiment 1, and the brake control device includes a brake control module 101 and a pressure calculation module 102 .

[0079] The brake control module 101 is used to control a plurality of isolation valves to be in a preset state.

[0080] That is, when the car is normally powered on and started, the first normally open isolation valve and the second normally open isolation valve are controlled to close, and the front and rear isolation valves are controlled to be turned on. In this way, the pressure generated by the pressure generating device can enter the corresponding main wheel cylinder through the accumulator, and finally enter the supporting wheel cylinder to realize braking.

[0081] The pressure calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com