A high-efficiency electrochemical desalination method and device based on intermittent energization

A desalination device and electrochemical technology, applied in construction, building maintenance, building construction, etc., can solve the problems of reduced possibility of steel bars, low electrochemical desalination efficiency, increased power consumption, etc., to prevent corrosion and accelerate electromigration. , the effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

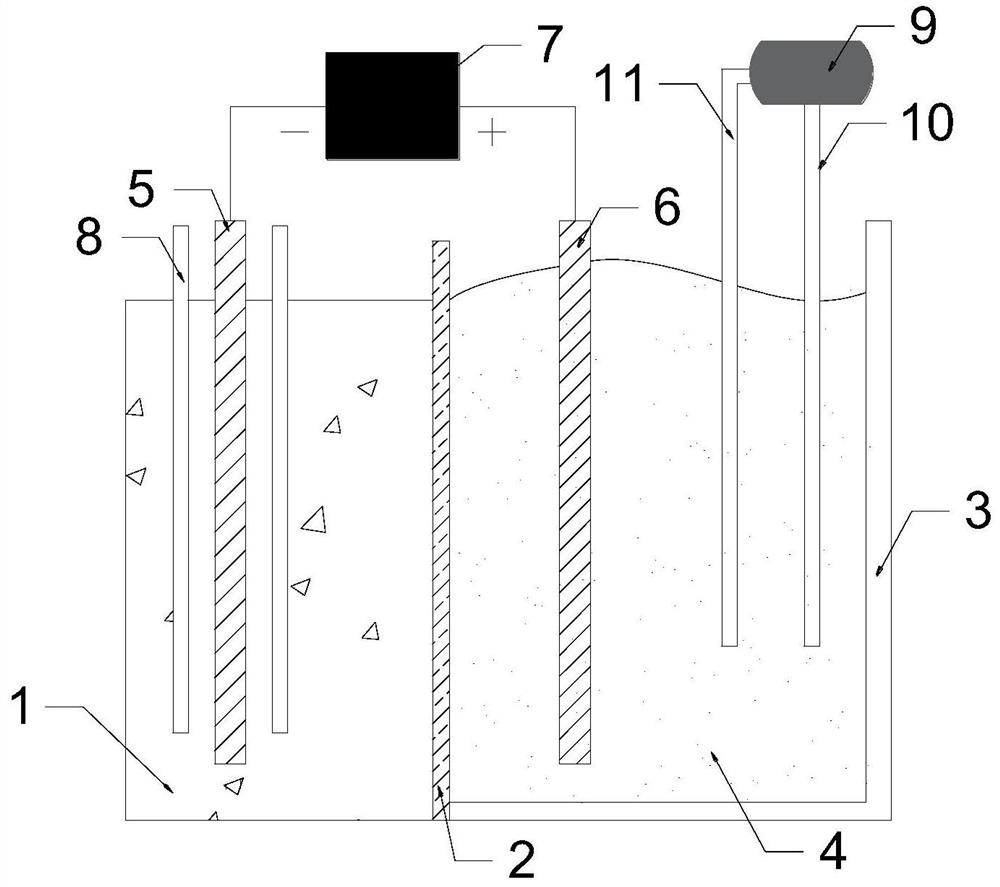

[0043] Embodiment 1 High-efficiency electrochemical desalination device based on intermittent energization

[0044] A high-efficiency electrochemical desalination device based on intermittent energization, see figure 1 , including a concrete specimen 1, an anode 6, an electrolytic cell 3 filled with an electrolyte 4, and a DC power supply 7, the positive pole of the DC power supply 7 is electrically connected to the anode 6 through an anode lead, and the negative pole of the DC power supply 7 is electrically connected through a cathode lead. Connect the steel bars 5 in the concrete test piece 1 to form a current loop after electrification, the electrolyte 4 is in contact with the surface of the concrete test piece 1, and the anode 6 is parallel to the concrete surface and immersed in the electrolyte In 4, in order to prevent the electrolyte 4 from overflowing, the edge of the electrolytic cell 3 is provided with a waterproof glue 2 to seal the edge of the electrolytic cell 3 a...

Embodiment 2

[0046] Embodiment 2 High-efficiency electrochemical desalination method based on intermittent energization

[0047] A high-efficiency electrochemical desalination method based on intermittent energization, comprising the steps of:

[0048] S1, using the steel bar in the concrete specimen as the cathode, construct an electrochemical reaction system comprising an anode, an electrolyte and a DC power supply, the anode preferably uses a titanium wire mesh, and the electrolyte is saturated Ca(OH) 2 Solution, while passing into the concrete test piece 0.2mol / L desalination accelerator, the desalination accelerator is Na 2 HPO 4 ;

[0049] S2. After the electrolyte is heated for 10 minutes, the DC power supply is energized to carry out electrochemical reaction; when the electrolyte is heated to 50°C, it remains constant; the voltage of the DC power supply is 20V, and the applied current density is the total surface area of the reinforcement mesh in the concrete Calculated as 2A / ...

Embodiment 3

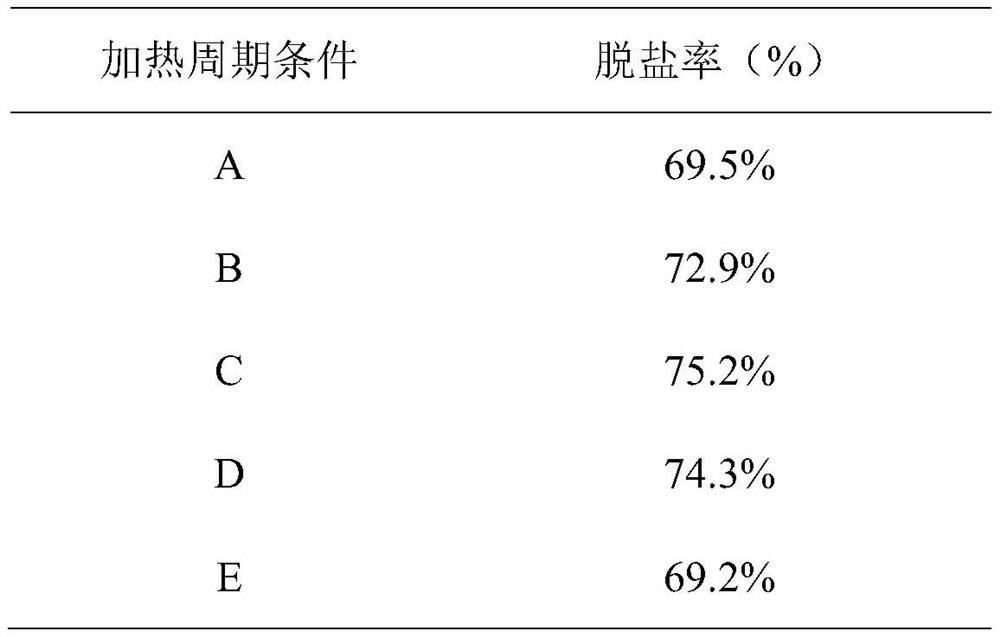

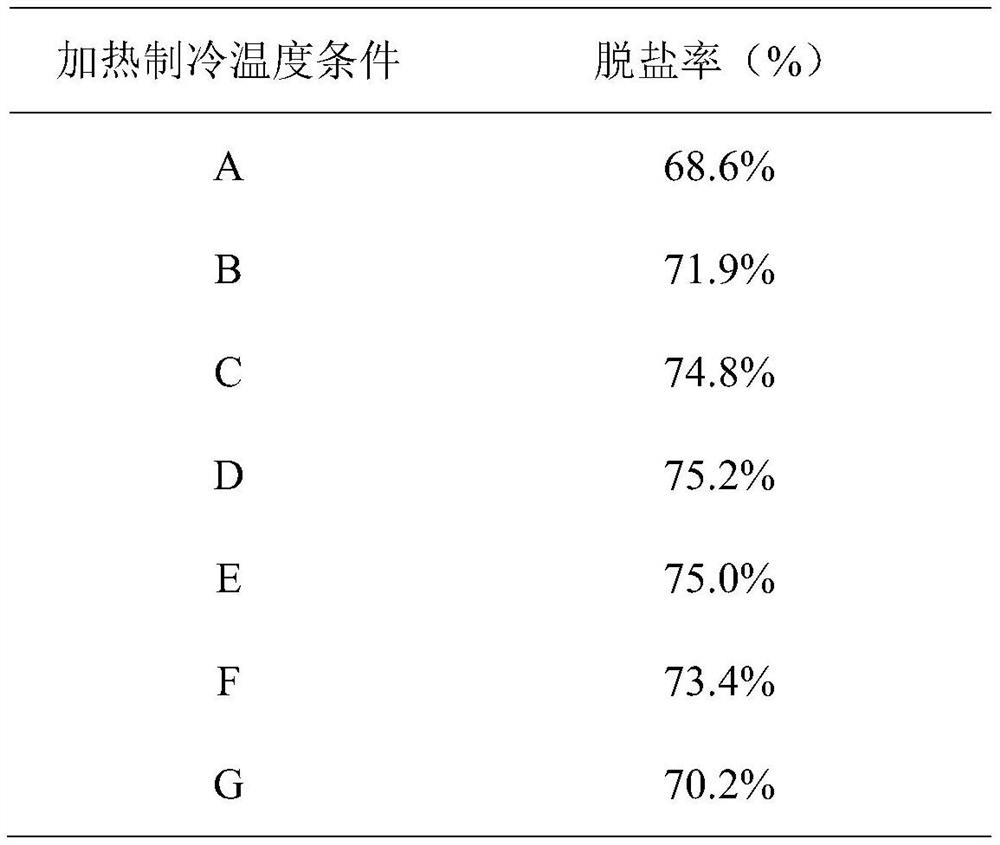

[0053] Embodiment 3 The optimization of intermittent heating of electrolyte and intermittent energization cycle of DC power supply

[0054] The concrete specimens to be desalted were divided into 5 groups, and electrochemical desalination experiments were carried out under different intermittent heating and energization cycle conditions, and the intermittent energization cycle was delayed by 10 minutes compared with the intermittent heating cycle; the rest of the experimental conditions were the same as in Example 2, with Evaluate the desalination efficiency;

[0055] Group A: The intermittent heating and power-on cycle is: heating and power-on for 40 minutes, cooling and power-off for 20 minutes;

[0056] Group B: The intermittent heating and power-on cycle is: heating and power-on for 50 minutes, cooling and power-off for 25 minutes;

[0057] Group C: The intermittent heating and power-on cycle is: heating and power-on for 60 minutes, cooling and power-off for 30 minutes; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com