Integrated electro-hydraulic servo rotary actuator

A rotary actuator and electro-hydraulic servo technology, applied in the field of servo actuators, can solve the problems of low control accuracy, small power density ratio and power volume ratio, and high space requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

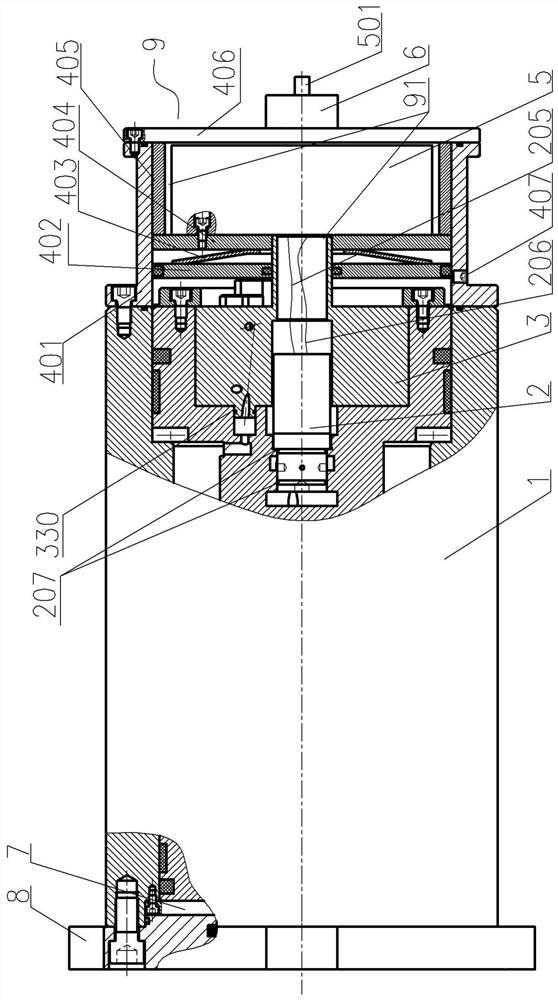

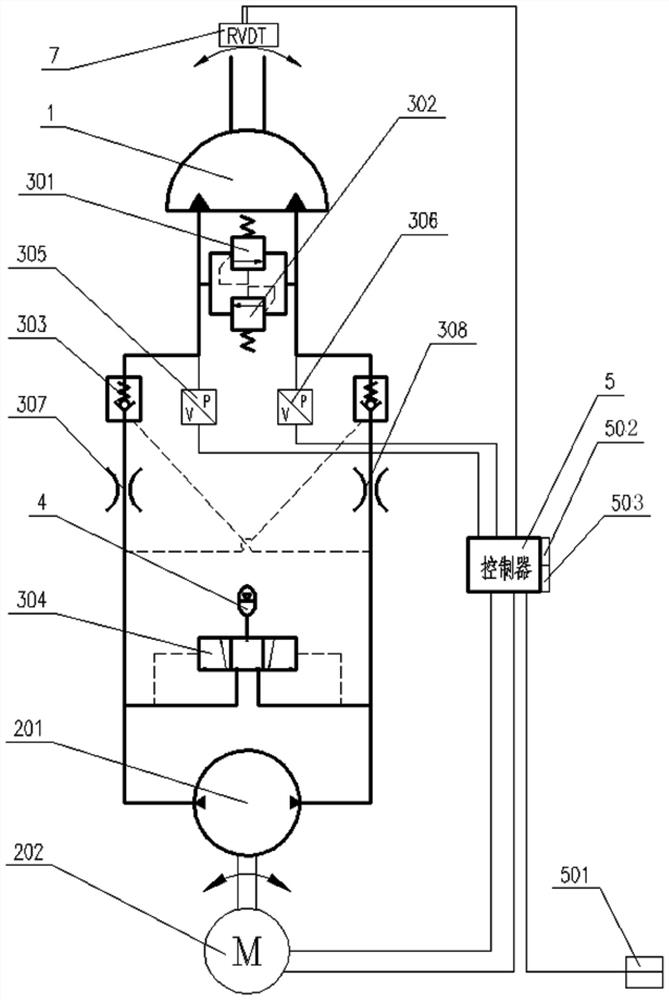

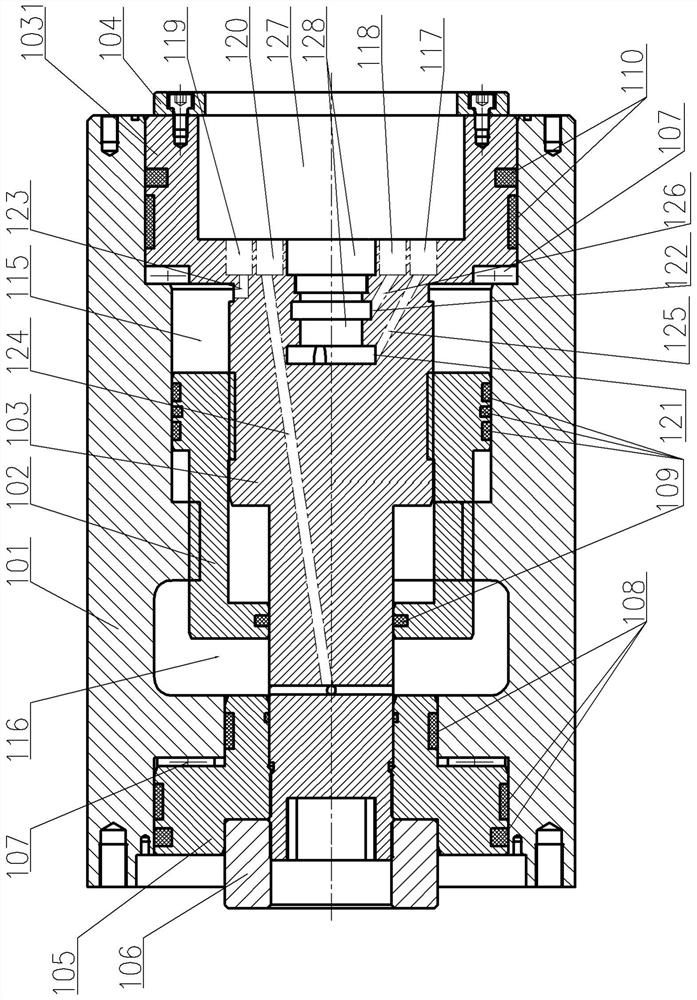

[0037] Integrated electrohydraulic servo rotary actuator, see Figure 1-Figure 8 : It includes a helical oscillating cylinder 1, an integrated motor pump 2, an integrated valve block 3, an accumulator 4, a controller 5, and an RVDT angle sensor 7. The helical oscillating cylinder 1 includes a cylinder body 101, an output shaft 103, and a piston 102. A piston 102 and an output shaft 103 are arranged in the inner chamber of the cylinder body 101. The piston 102 is meshed with the corresponding first meshing inner tooth of the inner chamber of the cylinder body 101 through the outer helical right tooth 113, and the outer cylindrical surface of the piston 102 is in contact with the cylinder body. The annulus of the inner wall of the inner cavity of the inner cavity is clearance fit to form a sealed contact connection. The connecting end of the output shaft 103 meshes with the inner helical left tooth 114 of the positioning cavity of the piston 102 through the outer helical left too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com