Method for measuring space curvature of deformable curved surface and method for manufacturing inductance type space curvature measuring sensitive element

A technology of spatial curvature and measurement method, which is applied to measurement devices, electrical devices, electromagnetic means, etc., can solve the problems of high cost, complicated measurement methods, inconvenient engineering operations, etc., and achieves high temperature resistance, high sensitivity, and measurement handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

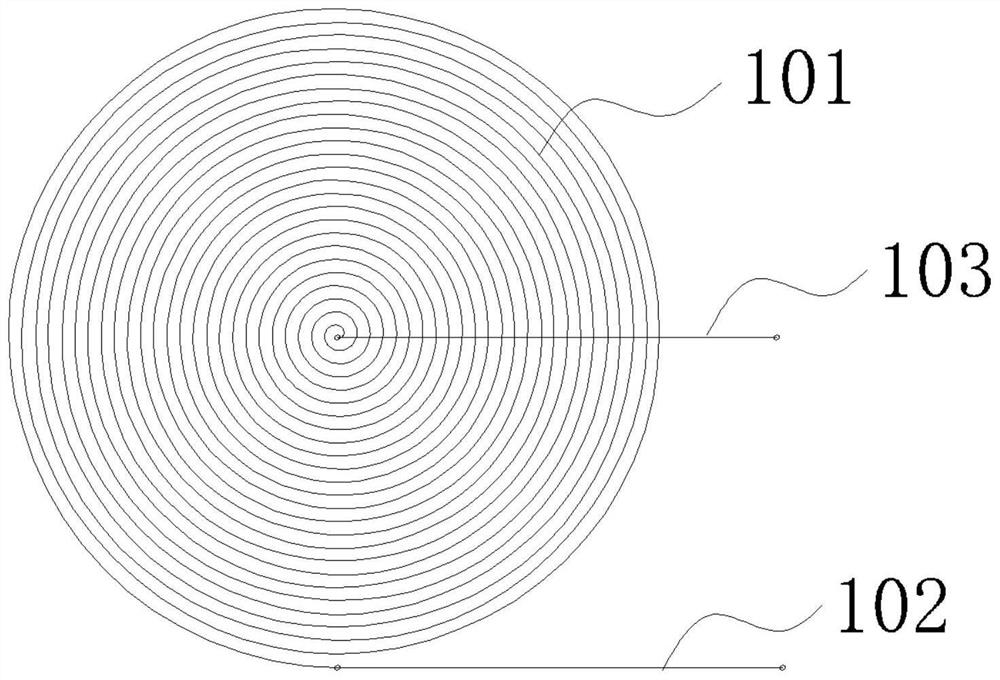

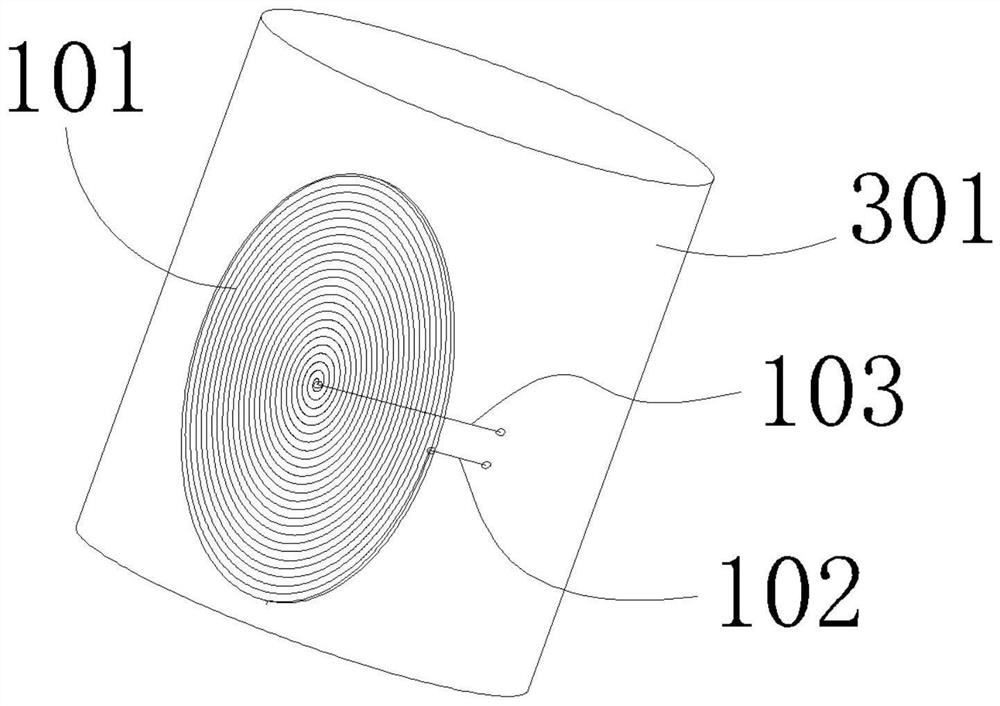

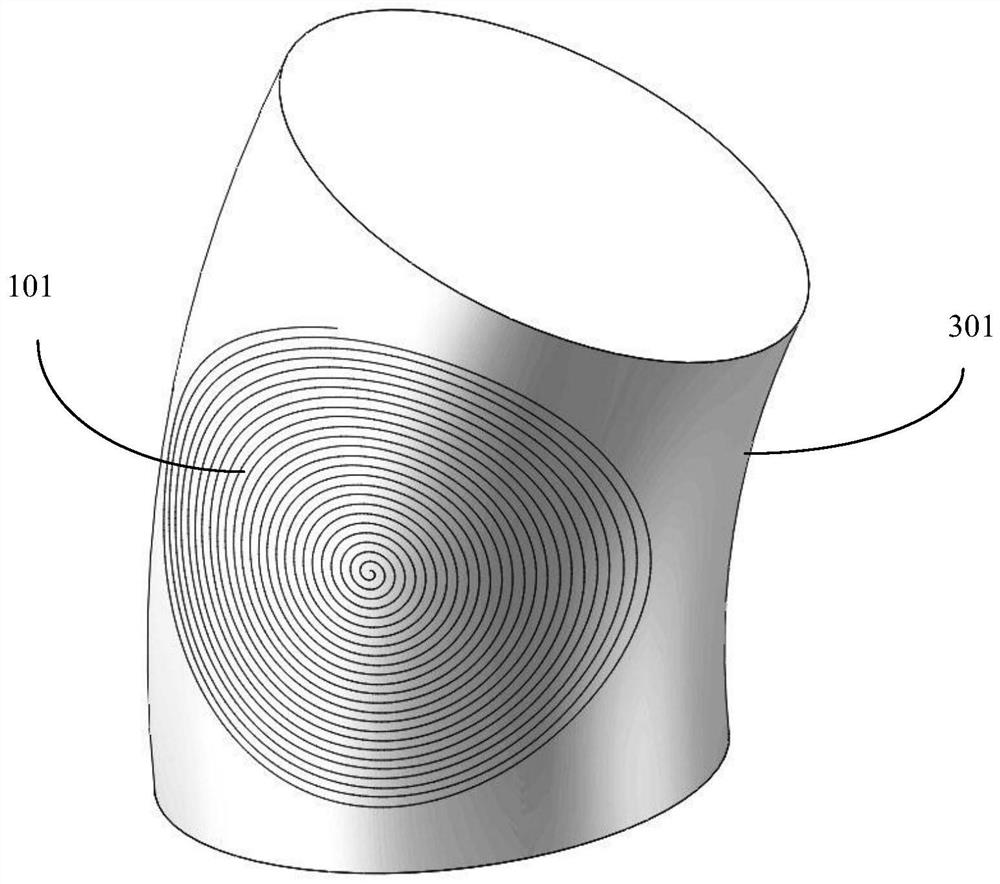

[0052] Such as figure 1 As shown, the inductive spatial curvature measurement sensitive element includes: a circular conductive carbon ink coil 101 , an interface lead 102 and an interface lead 103 . The circular conductive carbon ink coil 101 is provided with multiple turns, and the adjacent turns are insulated. The interface lead 102 is connected to one end of the circular conductive carbon ink coil 101 , and the interface lead 103 is connected to the other end of the circular conductive carbon ink coil 101 . The material of the circular conductive carbon ink coil 101 is conductive carbon ink.

[0053] When the inductive space curvature is used to measure the sensitive element, the circular conductive carbon ink coil 101 is printed or pasted on the measured object in the shape of a circle. When printing or pasting, arrange as many turns as possible to improve the sensitivity of sensitive components.

[0054] Such as figure 2 As shown, the inductive spatial curvature mea...

Embodiment 2

[0085] This embodiment introduces the rectangular shape coil structure, such as Figure 10 In the single rectangular conductive carbon ink coil 201 shown, the rectangular conductive carbon ink coil 201 is provided with multiple turns, and the adjacent turns are insulated. The interface lead 202 is connected to one end of the rectangular conductive carbon ink coil 201 , and the interface lead 203 is connected to the other end of the rectangular conductive carbon ink coil 201 . The number of lead wire interfaces is also selected according to the accuracy of the specific object to be measured and the range of surface curvature change.

[0086] Such as Figure 11 As shown, or a plurality of rectangular conductive carbon ink coils 201 can also be used as a whole, and the number of lead wire interfaces is also specifically selected according to the accuracy of the specific object to be measured and the range of surface curvature change.

[0087] The process of applying to the meas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com