Device for Measuring Permeability of High Temperature and High Pressure Foam Liquid Film and Its Application Method

A high temperature and high pressure, foam liquid technology, applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. , Simple operation, high degree of automation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

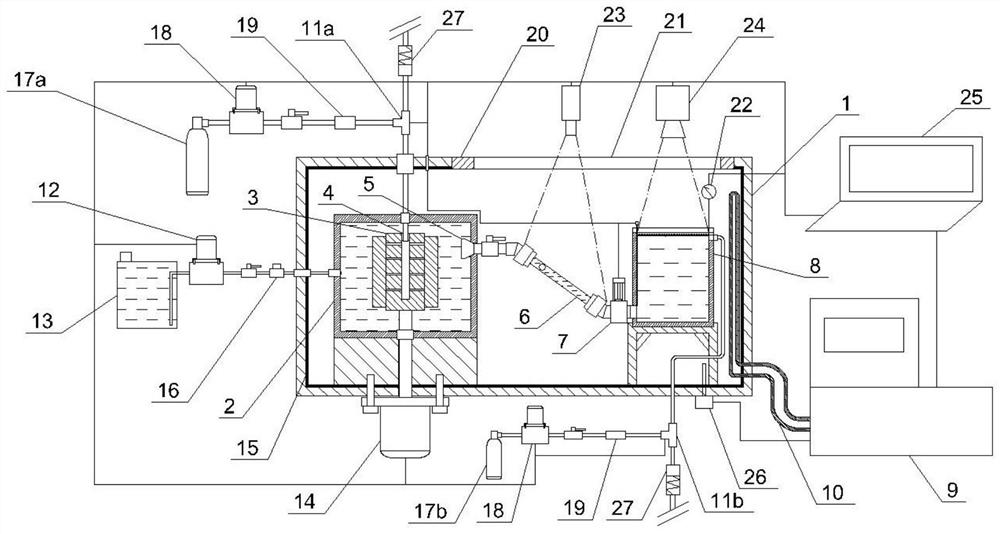

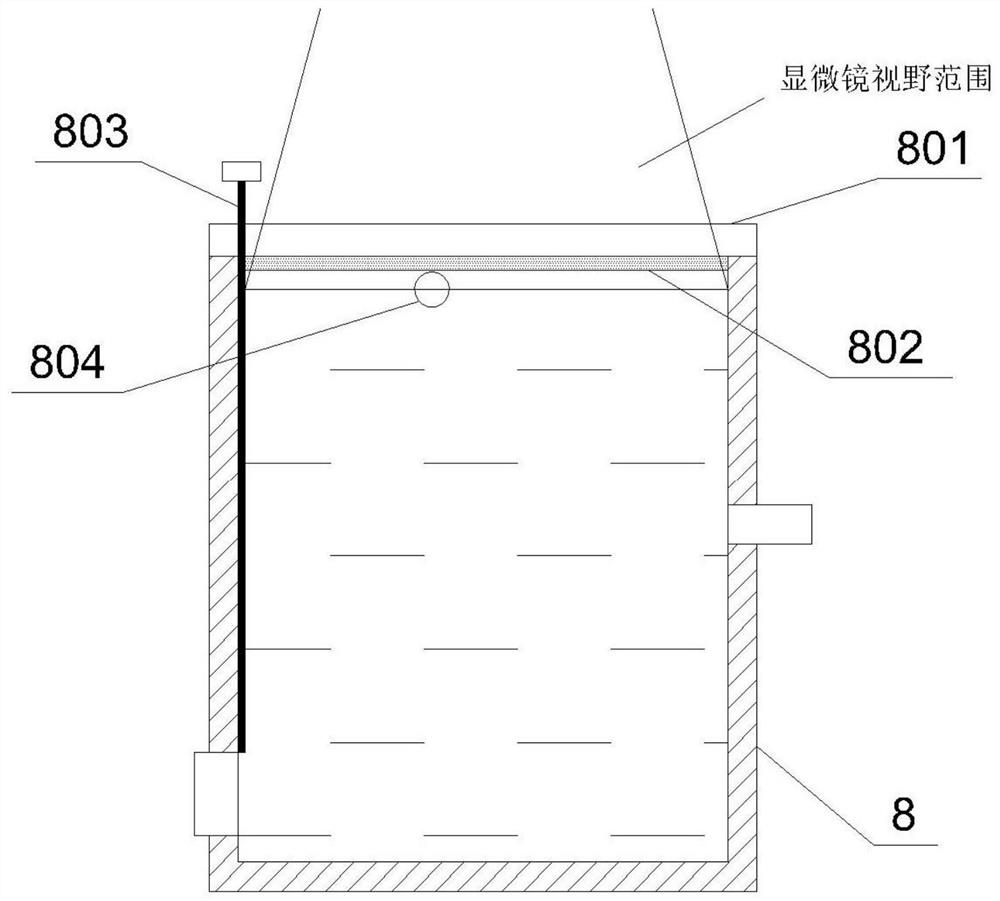

[0048] see Figure 1 to Figure 5 , a device for measuring the permeability of high-temperature and high-pressure foam liquid film:

[0049] The upper surface of the device body 1 is detachably provided with a device cover 20 with a glass observation window 21, and its inner surface is laid with a heat-insulating jacket 15 made of heat-resistant rubber, and the inner surface of the device body is lined with a heat-insulating jacket 15, can maintain its internal temperature;

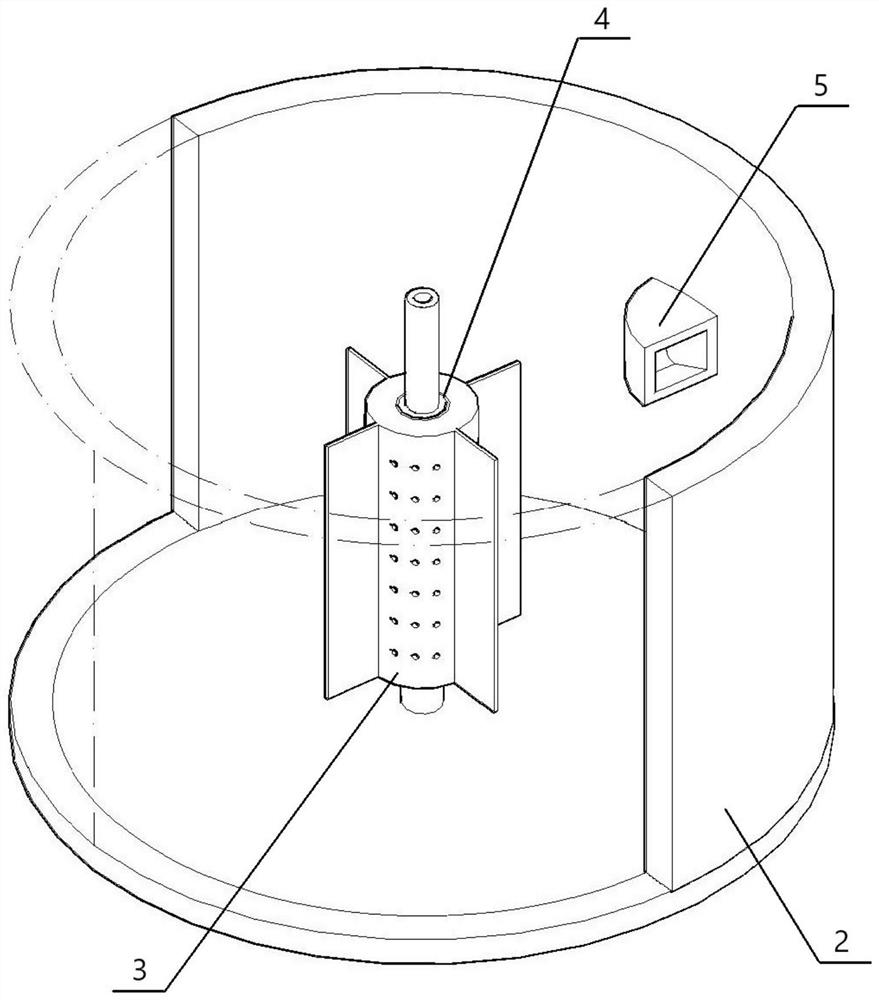

[0050] The bubble generator 2 is made of stainless steel, installed inside the device body 1, and can withstand high temperature and high pressure conditions;

[0051] The inner wall of the bubble generator 2 is provided with a bubble collecting bucket 5, and the bubble collecting bucket 5 is provided with a bubble collecting port connected with the pipe head on one side of the bubble generator 2. Relatively, its essence is that it is opposite to the rotation tangential acceleration direction that produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com