Bagged material warehouse-in and warehouse-out metering method based on video analysis

A measurement method and video analysis technology, applied in image analysis, neural learning methods, color TV parts, etc., can solve problems such as error-prone, inaccurate inventory of hazardous chemicals, and easy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

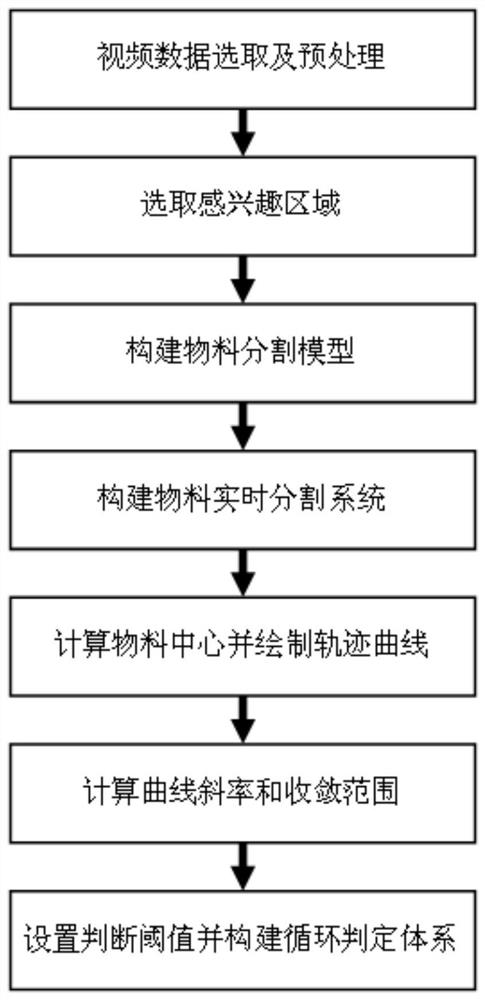

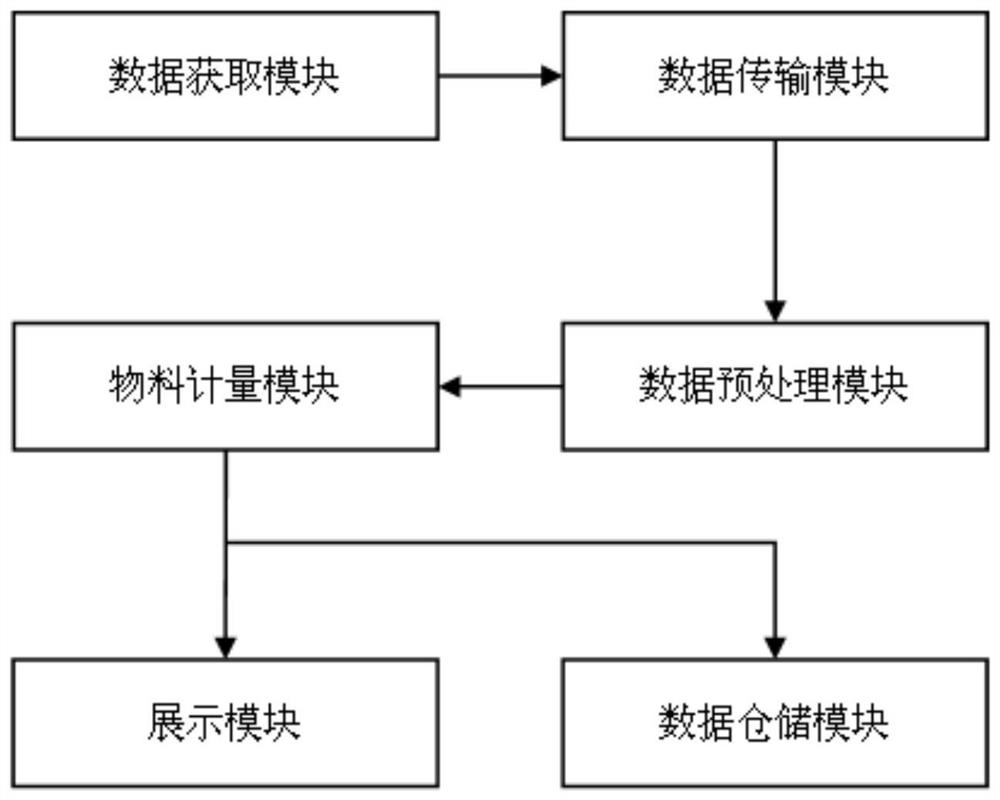

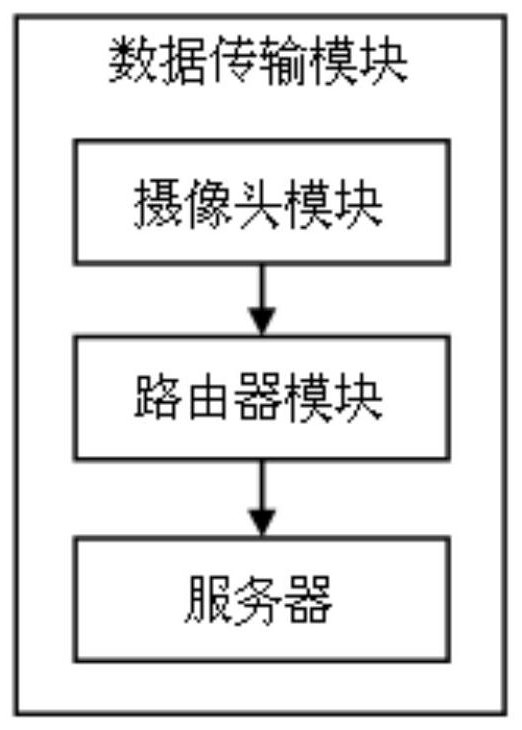

[0031] The invention provides a method for measuring bagged materials in and out of storage based on video analysis, which includes the following steps:

[0032] 1) Collect video image data through video sensor equipment;

[0033] 2) Select the region of interest in the video image data as the analysis object and perform preprocessing;

[0034] 3) Train the preprocessed data to build a real-time segmentation model for bagged material images;

[0035] 4) Use the real-time segmentation model of bagged material images to build a real-time material segmentation system, and calculate the area size of each segmentation result to determine the tracking material area;

[0036] 5) Calculate the center point of the tracking material area, and the coordinates of the center point are the required tracking targets;

[0037] 6) Draw a curve that tracks the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com