Cover plate, display panel and manufacturing method of cover plate

A display panel and cover technology, which is applied in the direction of identification devices, instruments, coatings, etc., can solve the problems of inconsistent brightness, inconsistent reflectivity, and affecting the user's visual perception, so as to improve visual perception, improve visual effects, and improve visual perception. The effect of perception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

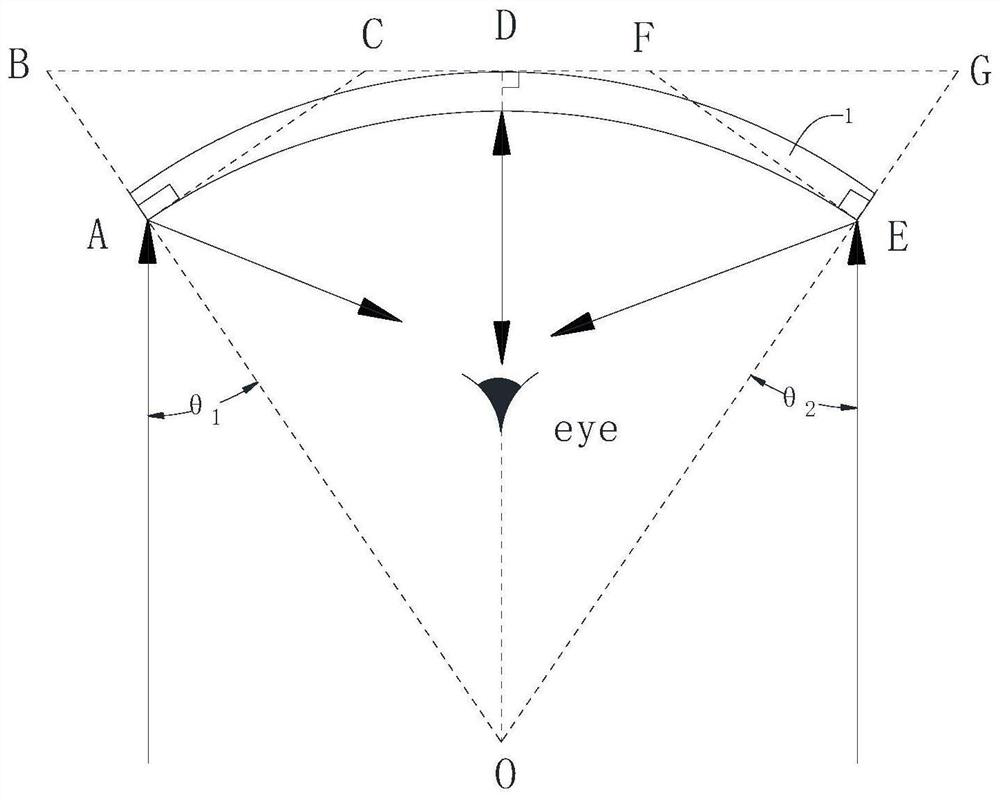

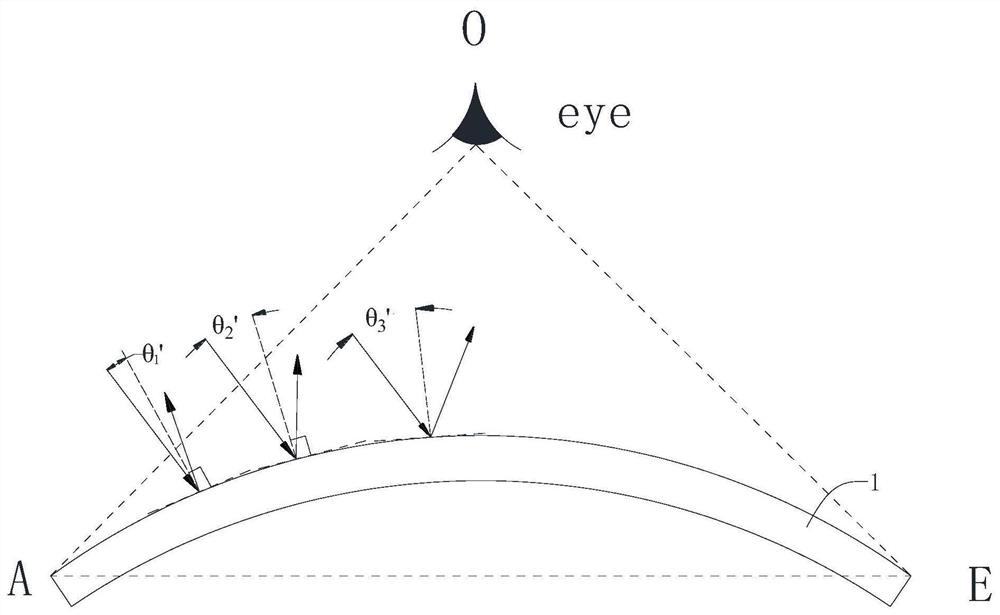

[0076]Experimental example 1 includes a curved cover plate, and the curved cover plate is used for a concave curved display panel. The curved cover plate includes a base 12 and two layers of anti-reflection films 13 arranged on the light-emitting surface 122 of the base 12. The first refractive index film layer 131 in each anti-reflection film 13 is made of Nb 2 o 5 (Niobium pentoxide) material, and the refractive index is the same everywhere in the curved surface parallel to the light-emitting surface 122 of the substrate 12 . The second refractive index film layer 132 is made of SiOxNy material. The second refractive index film layer 132 adjusts the ratio of nitrogen and oxygen in the SiOxNy material, so that the refractive index of the second refractive index film layer 132 in the first direction X is in a decreasing distribution from the central area to the edge area of the cover plate. In some examples, the higher the oxygen content and the lower the nitrogen content ...

experiment example 2

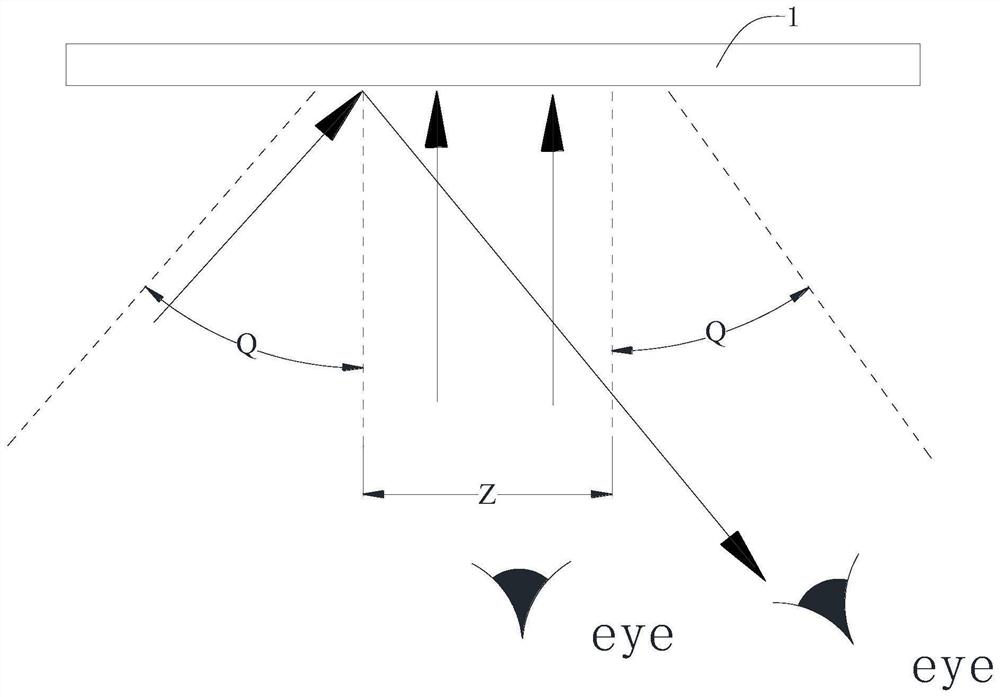

[0086] Experimental Example 2 includes a straight cover plate, and the straight cover plate is used for a flat display panel. The flat cover plate includes a base and two layers of anti-reflection films arranged on the light-emitting surface of the base, and the first refractive index film layer in each anti-reflection film is made of Nb 2 o 5 (Niobium pentoxide) material, and the refractive index is the same everywhere in the plane parallel to the light-emitting surface of the base. The second refractive index film layer is made of SiOxNy material. The second refractive index film layer adjusts the nitrogen-oxygen ratio in the SiOxNy material, so that the refractive index of the second refractive index film layer presents a decreasing distribution from the central area to the edge area of the cover plate in the length direction of the flat display panel. In some examples, the higher the oxygen content and the lower the nitrogen content in the SiOxNy material, the SiOxNy m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com