Optimized structure of photovoltaic module

A technology for photovoltaic modules and structure optimization, applied in the field of solar modules, can solve the problems of reducing the service life of the cells, heating the cells, affecting the power generation of the modules, etc., to achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

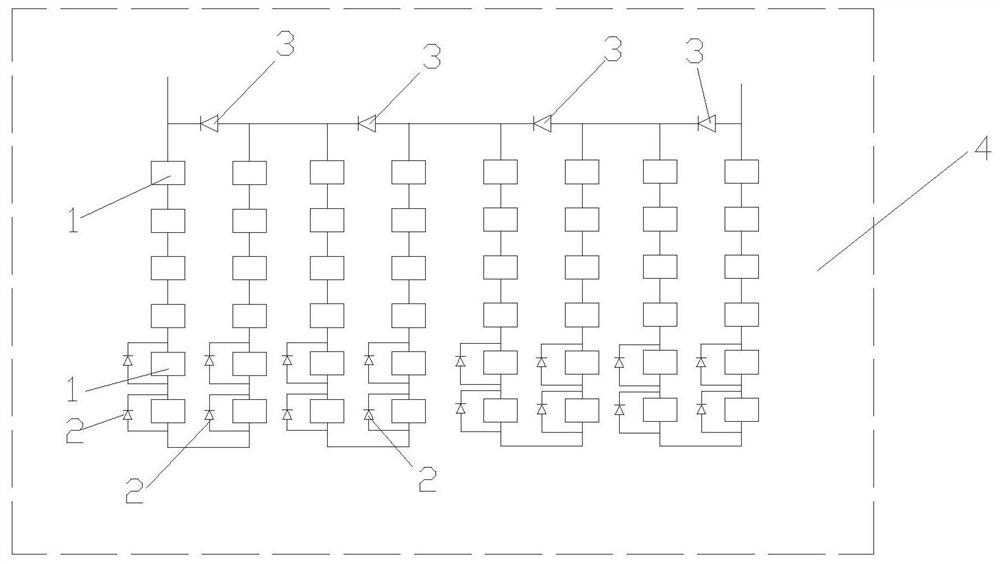

Embodiment 1

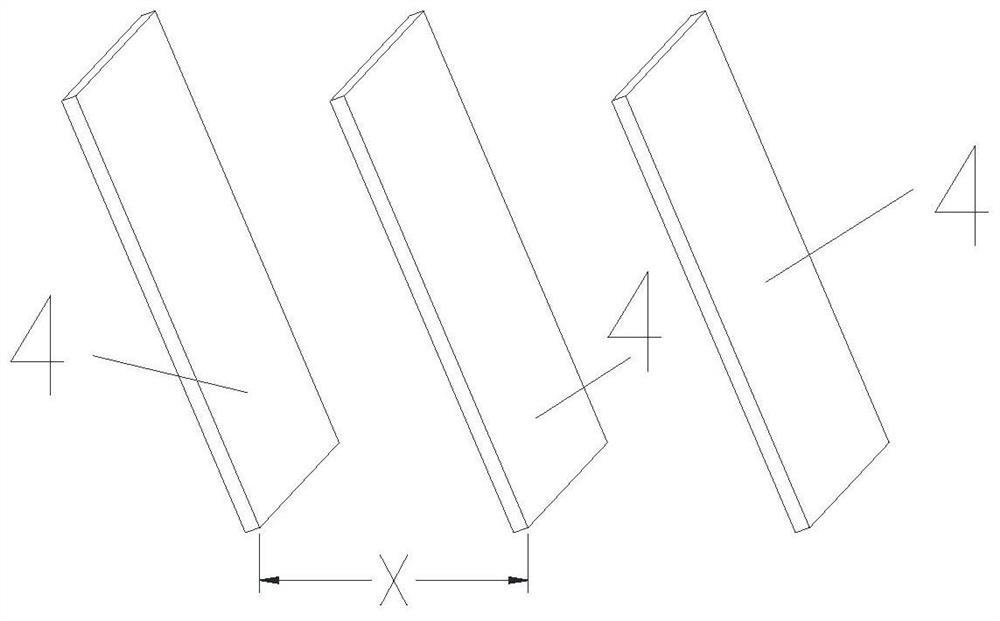

[0014] As shown in the figure, an optimized structure of a photovoltaic module includes several groups of photovoltaic modules 4, and each group of photovoltaic modules 4 is composed of cells 1 arranged in a matrix in series, between two adjacent groups of photovoltaic modules 4 The distance is X, and the photovoltaic modules 4 located in the rear of the two adjacent groups of photovoltaic modules 4 have a diode-2 connected between the positive and negative poles of the Y row of battery sheets 1, and the diode-2 is installed. The relationship between the row number Y of battery sheets 1 and the distance X between two adjacent groups of photovoltaic modules 4 is Y=round(-6.36X+11.09). Such as figure 1 As shown, this embodiment takes the vertical arrangement of battery slices 1 as an example for illustration. The number of battery slices 1 in the same row is 6, the number of battery slices 1 in the same row is 8, and there are two rows of battery slices 1 on the bottom. Diodes ...

Embodiment 2

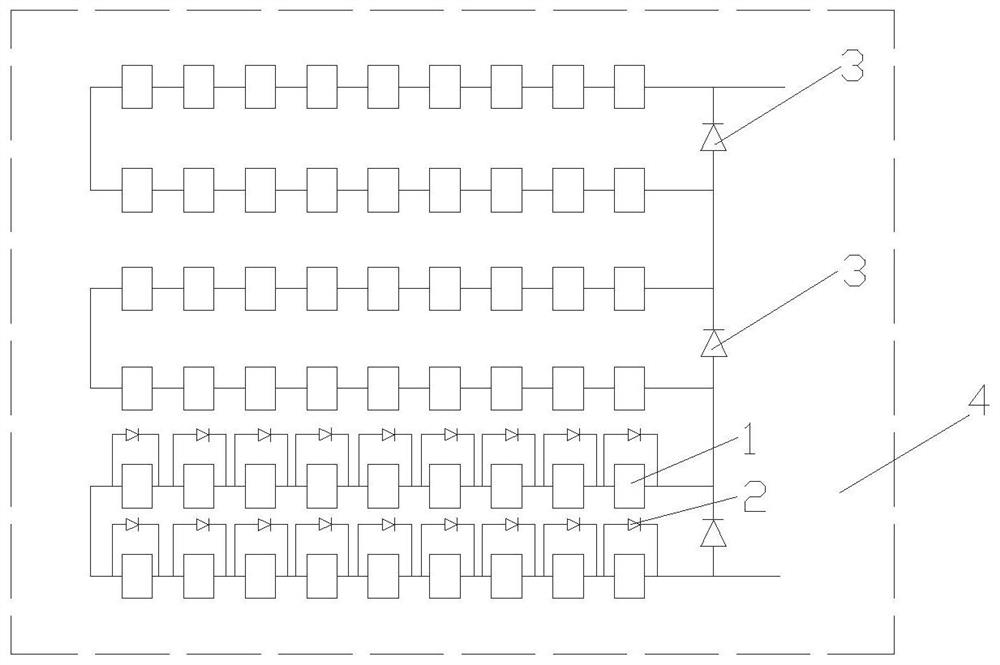

[0017] The difference from Embodiment 1 is that: figure 2 As shown, this embodiment is described by taking the horizontal arrangement of battery sheets 1 as an example. The number of battery sheets 1 in the same row is 6, and the number of battery sheets 1 in the same row is 9. There are two rows of battery sheets 1 on the bottom. Diode 1 is connected in parallel. The battery slices 1 arranged in matrix in each group of photovoltaic modules 4 are located between several battery slices 1 in the same row and connected in series to form a battery pack.

[0018] Effect verification: Both the conventional module and the optimized module are SEAC60-310W. The power generation of the two types of modules is compared through experiments. 20 groups of conventional and optimized modules are respectively connected to the same type of inverter and meter, installed facing south, and the inclination angle 23°, build a grid-connected system, and use a meter to record the power generation. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap