Automatic mounting device for storage battery protective screen plate

A technology of automatic installation and protective net, applied in battery assembly, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of complicated cutting and installation operations, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

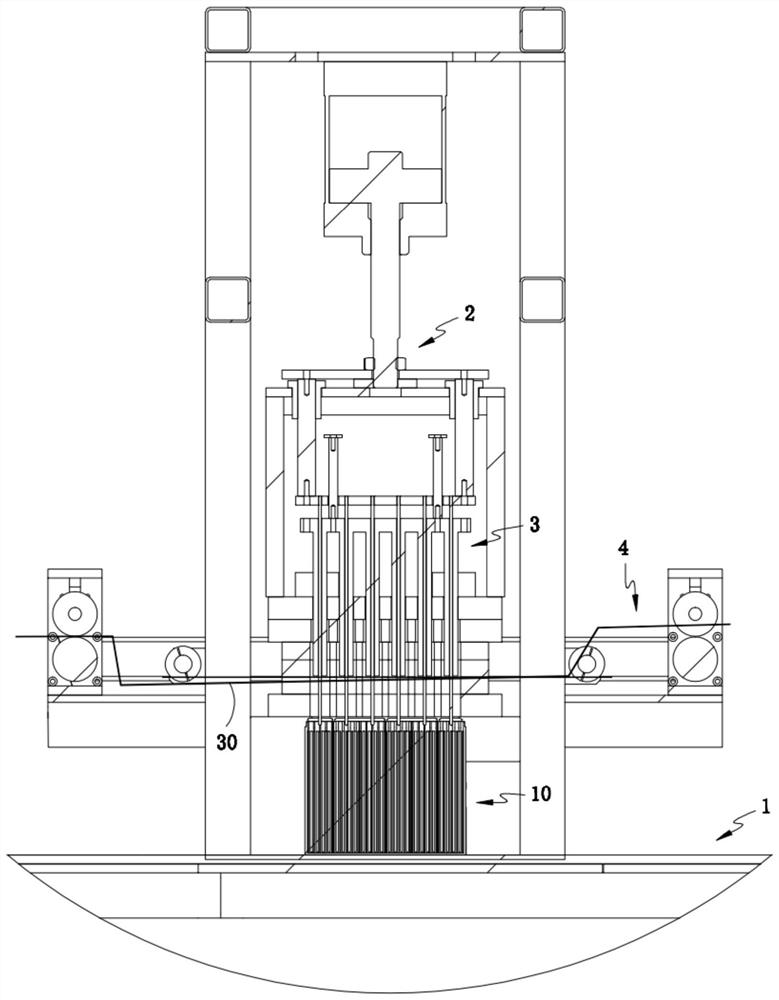

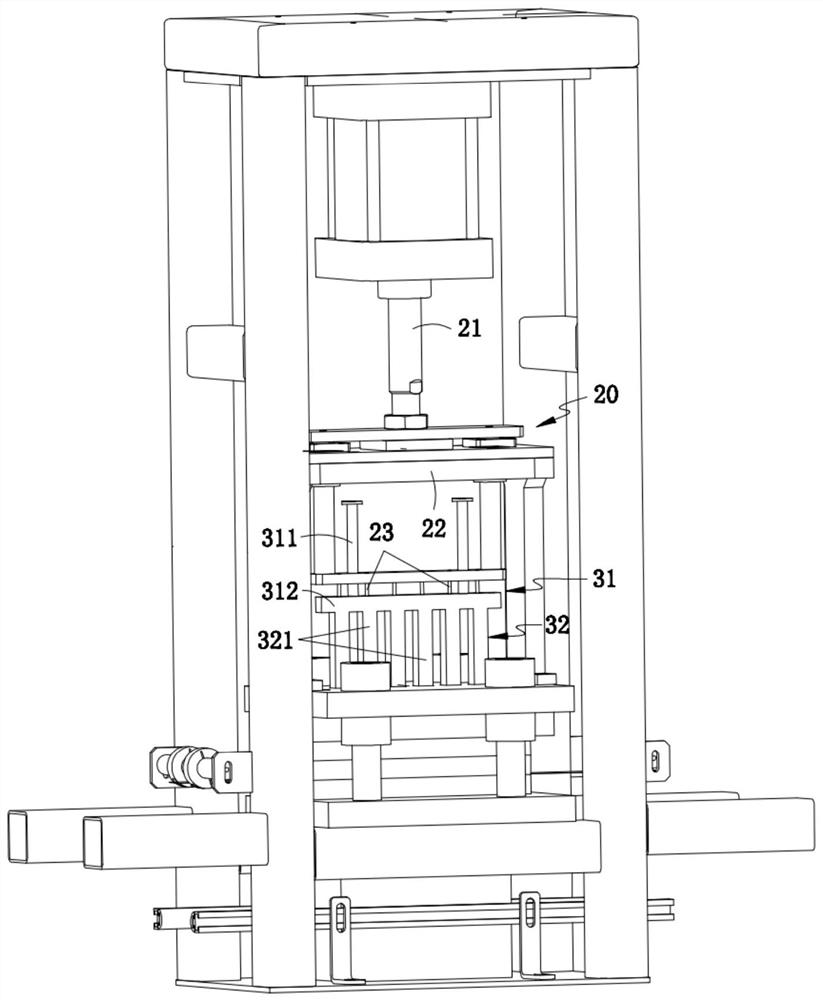

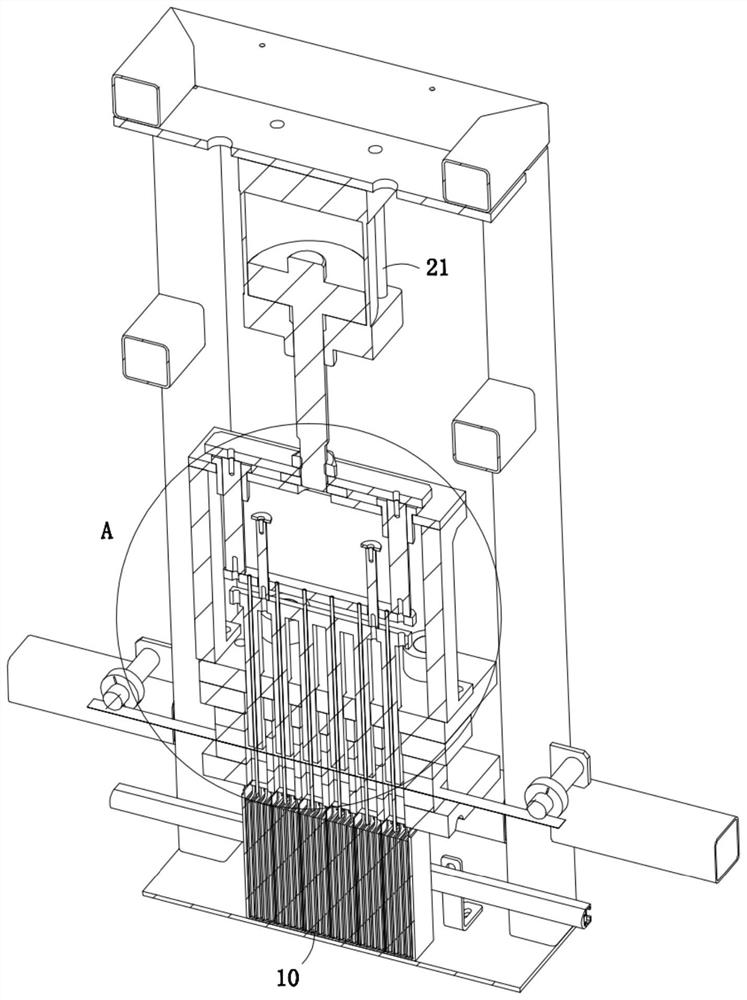

[0031]Such asfigure 1 As shown, the battery protective mesh is automatically mounted, including the frame 1 and a battery 10 placed on the frame 1, and the radial belt 30 is transmitted over the upper portion, and further includes mounted to the rack 1. The protective mesh mounting mechanism on the protective mesh belt 30, the guard mesh mounting mechanism including a positioning unit 2 and a crop unit 3 mounted on the positioning unit 2, the positioning unit. 2 After the splitting unit 30 is performed, the cut unit 3 is removed from the protective mesh 30 and positioned to the battery 10 downward.

[0032]In the present embodiment, the horizontal transmission protective end belt 20 is matched above the battery 10, and the protective mesh mounting mechanism is provided above the protective mesh 20, the protective mesh mounting mechanism includes a positioning unit 2 and a crop unit 3, which is protected. A through hole is provided on the messel side, and the positioning unit 2 can move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com