Method and device for detecting and identifying air leakage of explosion-proof valve of battery cover plate

A technology of battery cover and identification device, which is applied in battery/battery leak test, exhaust plug device, battery cover/end cover, etc. It can solve the problems of missing inspection and mixing materials, and achieve the effect of preventing external force damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

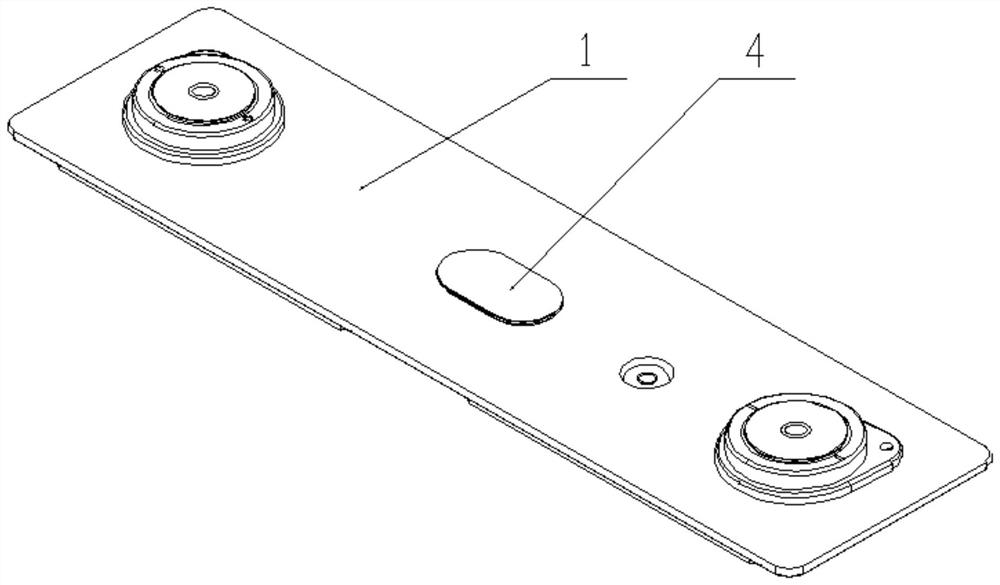

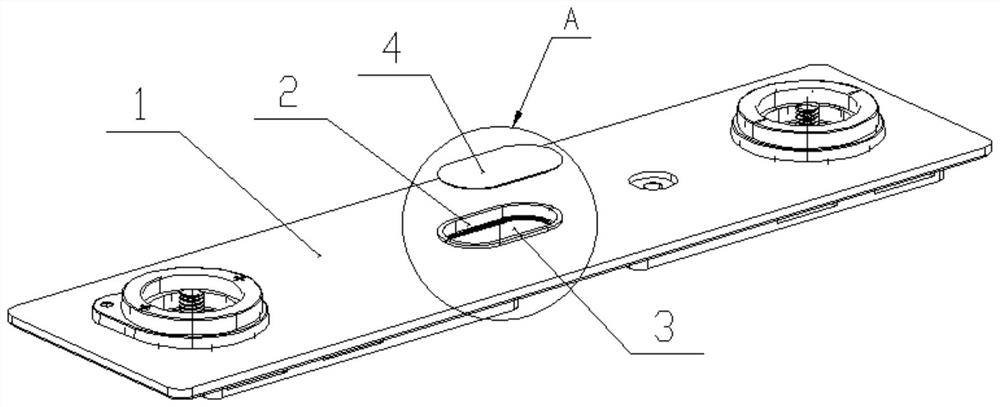

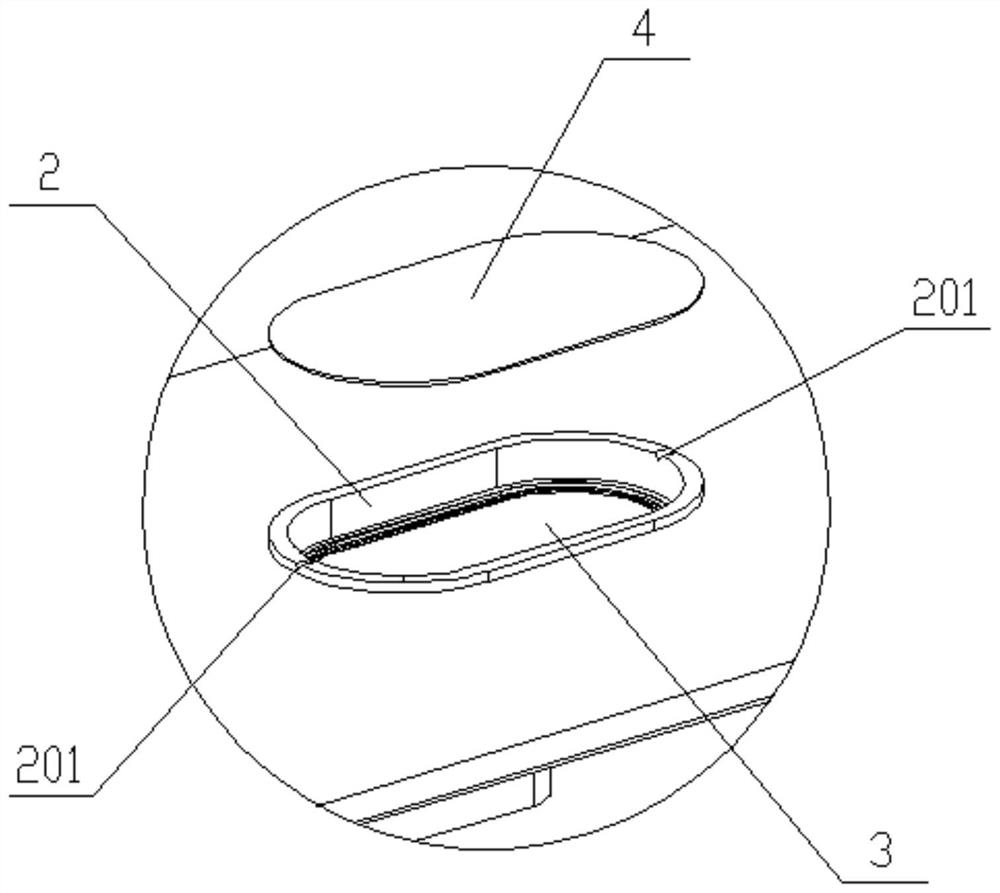

[0026] see Figure 1-Figure 7 , this embodiment provides a method for detecting and identifying air leakage of a battery cover explosion-proof valve, including a battery body and a battery cover 1 installed on the upper part of the battery body, an explosion-proof valve 3 is arranged in the middle of the battery cover 1, and an explosion-proof valve 3 is arranged on the top There is an air leakage identification unit 4, and the air leakage identification unit 4 is equipped with an air leakage detection test paper 402. After the battery is filled with electrolyte, if the explosion-proof valve 3 leaks the electrolyte due to welding quality defects, the gas generated after the leaked electrolyte contacts the air After touching the air leakage detection test paper 402, the color of the air leakage detection test paper 402 will change. Observe with the naked eye whether the color of the air leakage detection test paper 402 changes, as a basis for judging whether the explosion-proof ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com