3D printing make-up mask and manufacturing method thereof

A production method and color printing technology, applied in the field of 3D printing, can solve the problems that make-up technology and products are difficult to meet the needs of use, take up the user's time and energy, and the facial fit is not tight enough, so as to save makeup time and save money. Time, the effect of using comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

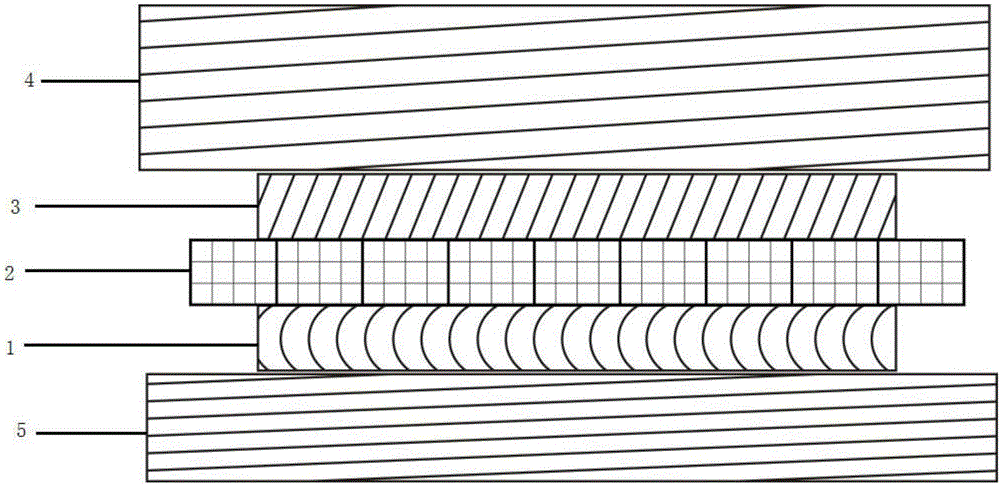

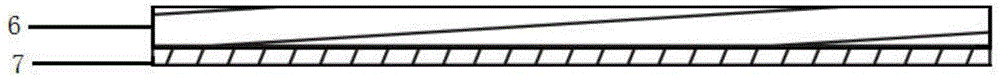

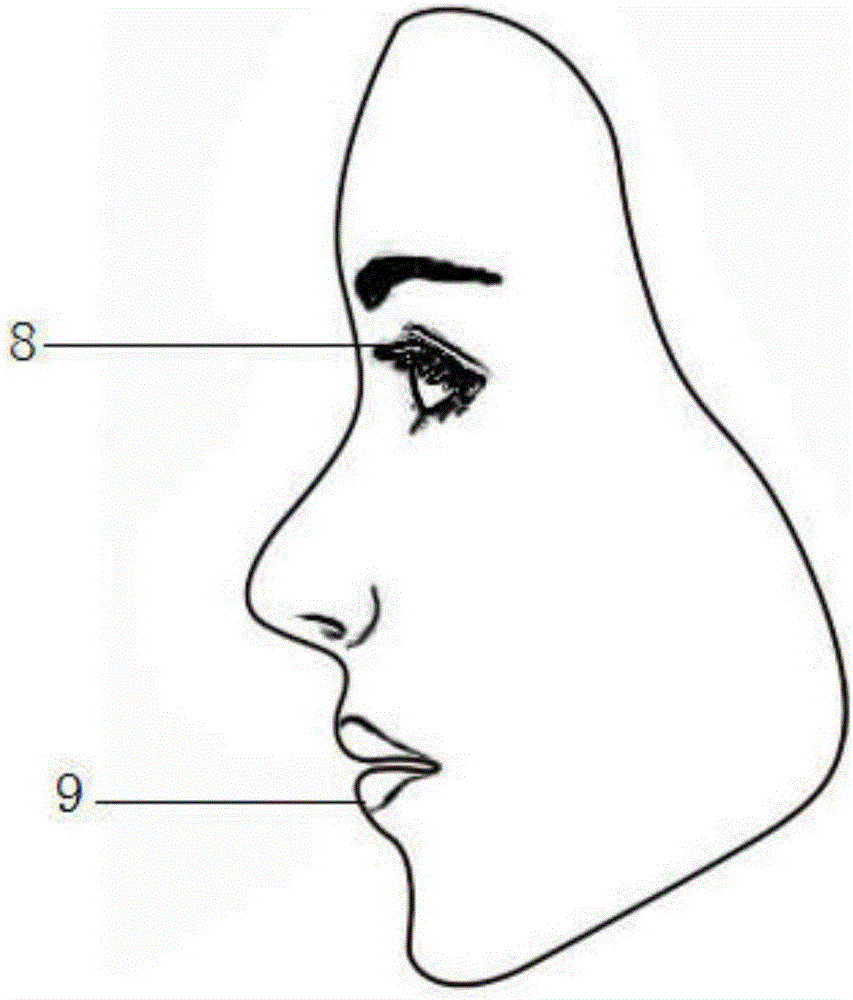

[0033] see figure 1 , figure 2 , the 3D printing makeup mask provided by the present invention, the mask is reserved with the contour gaps of eye sockets, nostrils and mouth, specifically comprising: a contact layer 1, a makeup layer 2 and a reinforcement layer 3, the reinforcement layer 3 is transparent or translucent; the contact layer 1 is closely attached to the facial skin, and the contact layer 1 is consistent with the contour of the user's face, and has openings and specific contours of various parts such as the mouth, eye sockets, and nose; the contact layer 1 is provided with a makeup layer 2, and the makeup layer 2 According to the user's needs, the makeup style and the color concentration of each part are preset in advance, such as heavy makeup, light makeup, personalized magic makeup and other styles. The make-up layer 2 is provided with a rein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com