Integrated antenna, manufacturing method thereof and integrated electronic device

An integrated antenna and manufacturing method technology, applied in the direction of antenna grounding switch structure connection, radiation element structure, etc., can solve the problems of short service life, low production efficiency, poor stability of integrated antenna connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

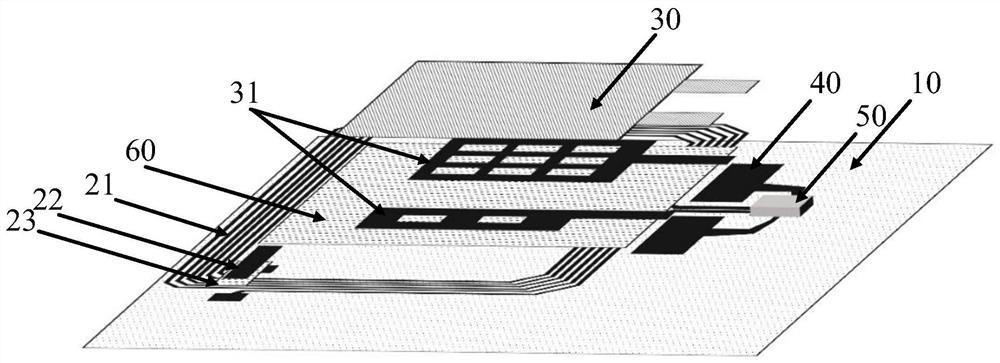

[0067] As a preferred embodiment, the thin film battery 30 includes a collector layer 31 . Some batteries have high internal resistance, so it is necessary to further print the collector layer 31 to reduce the internal resistance. The common collector layer 31 is a conductive paste layer, such as carbon paste and silver paste layer.

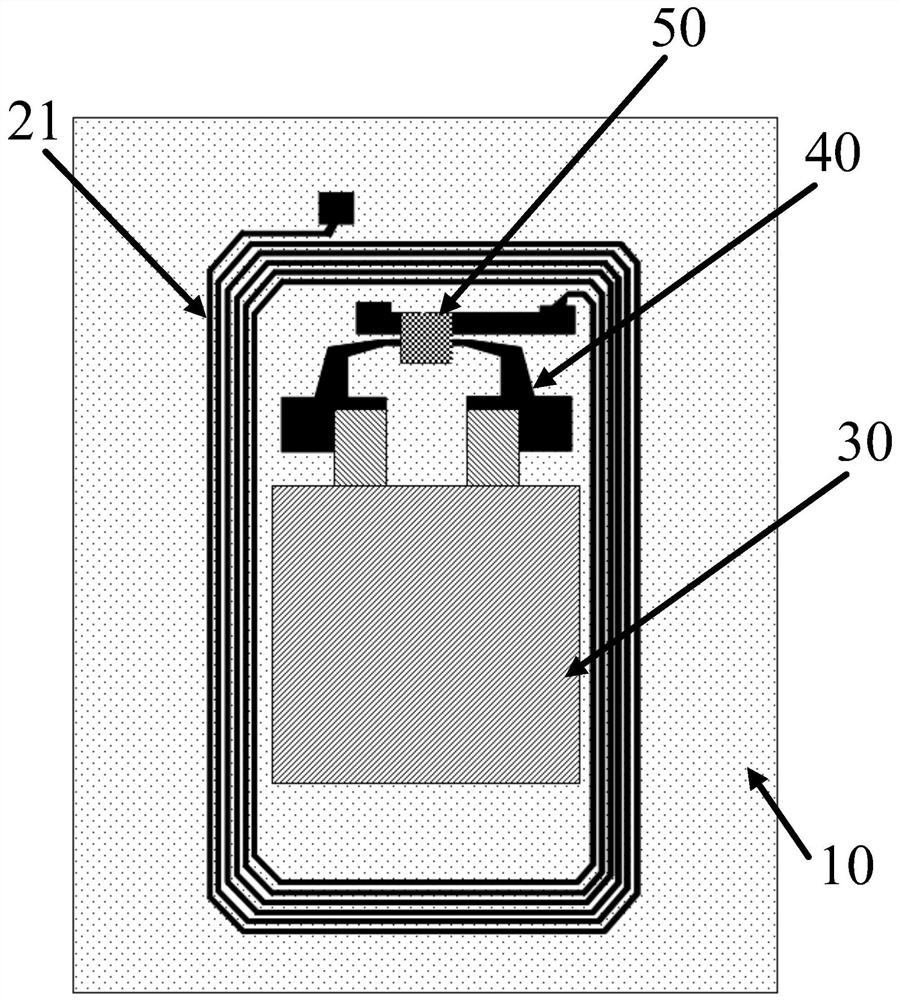

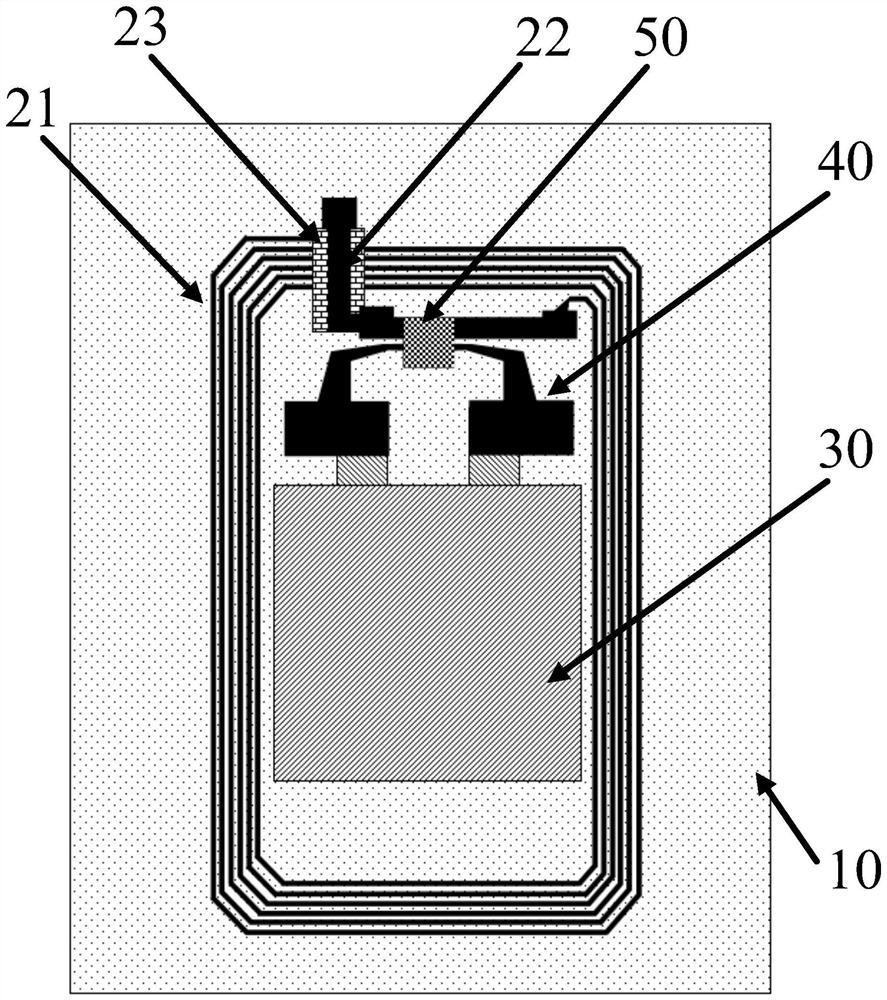

[0068] It should be noted that when the antenna conductive bridge 22 and the antenna coil 21 are arranged on the same side of the flexible substrate 10;

[0069] An antenna insulating bridge 23 is disposed between the antenna conductive bridge 22 and the antenna coil 21 .

[0070] Since the antenna coil 21 is generally ring-shaped, and the two ends are located on the inner side and the outer side of the ring respectively, to electrically connect these two ends, it must cross the ring itself, as Figure 5 Among them, on the other side of the flexible substrate 10 different from the antenna coil 21, it is connected through the antenna conductive b...

specific Embodiment approach 3

[0071] In addition, the present invention also provides a method for manufacturing an integrated antenna, the flow chart of which is shown in Figure 7 As shown, it is referred to as the third specific embodiment, including:

[0072] S1: setting the flexible substrate 10 .

[0073] S2: Printing and preparing thin film battery 30, radio frequency antenna 20 and power supply electrode 40 on the flexible substrate 10 to obtain an integrated front; wherein, the radio frequency antenna 20 includes an antenna coil 21 and an antenna conductive bridge 22; the antenna conductive bridge 22 connects the two ends of the antenna coil 21 and the thin film battery 30 is insulated from the radio frequency antenna 20; the thin film battery 30 is insulated from the radio frequency antenna 20.

[0074] The printing and preparation of thin film battery 30, radio frequency antenna 20 and power supply electrode 40 on the flexible substrate 10 includes:

[0075] printing the thin film battery 30 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com