Automatic removing device for dead leaves of potted rosa chinensis minima

An automatic removal and rose technology, which is applied to the cleaning of flowerpots, gardening, and botanical equipment and methods, etc., can solve problems such as poor operation, low efficiency, broken petioles, etc., and achieve the effect of strengthening the air blowing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

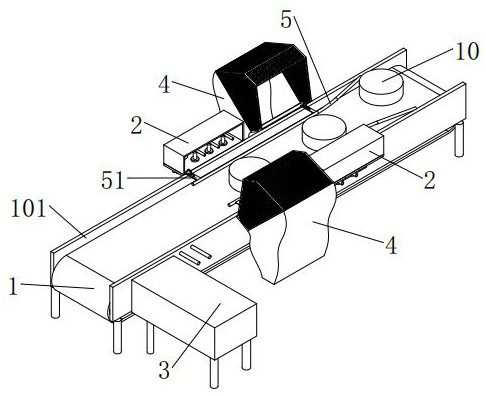

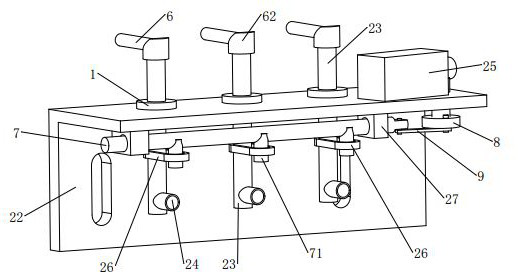

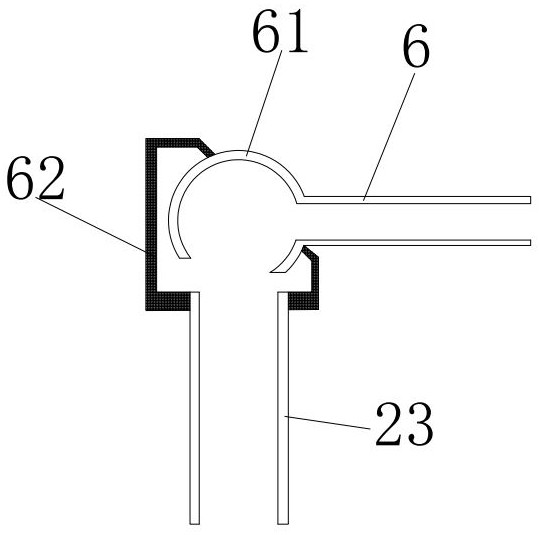

[0017] Such as figure 1 As shown, the automatic removal device for potted miniature rose dead leaves includes a conveyor belt 1 with sides 101 (the conveyor belt is actually very long, it is only short for display in the figure), two sets of air blowing devices 2 and several interlaced work Station 3, air blowing device 2 is equipped with an air supply machine with adjustable air volume, two sets of air blowing devices 2 are respectively located on both sides of the conveyor belt 1 to form a staggered distribution, and each group of air blowing devices 2 is provided with a net pocket 4 on the opposite side of the conveyor belt , each group of air blowing devices 2 is made up of three air blowing nozzles 6, the conveyor belt 1 is located in the corresponding area of the air blowing device 2 and is provided with a pair of adjusting rods 5, and the two ends of the same adjusting rod 5 are provided with a pole 51 with an adjusting hole, The sides of the conveyor belt 1 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com