Sertaconazole nitrate suppository and preparation method thereof

A technology of sertaconazole nitrate and conazole suppository, applied in the field of medicine, can solve problems such as low stability of sertaconazole nitrate suppository, increased cost, influence on the appearance of suppository and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

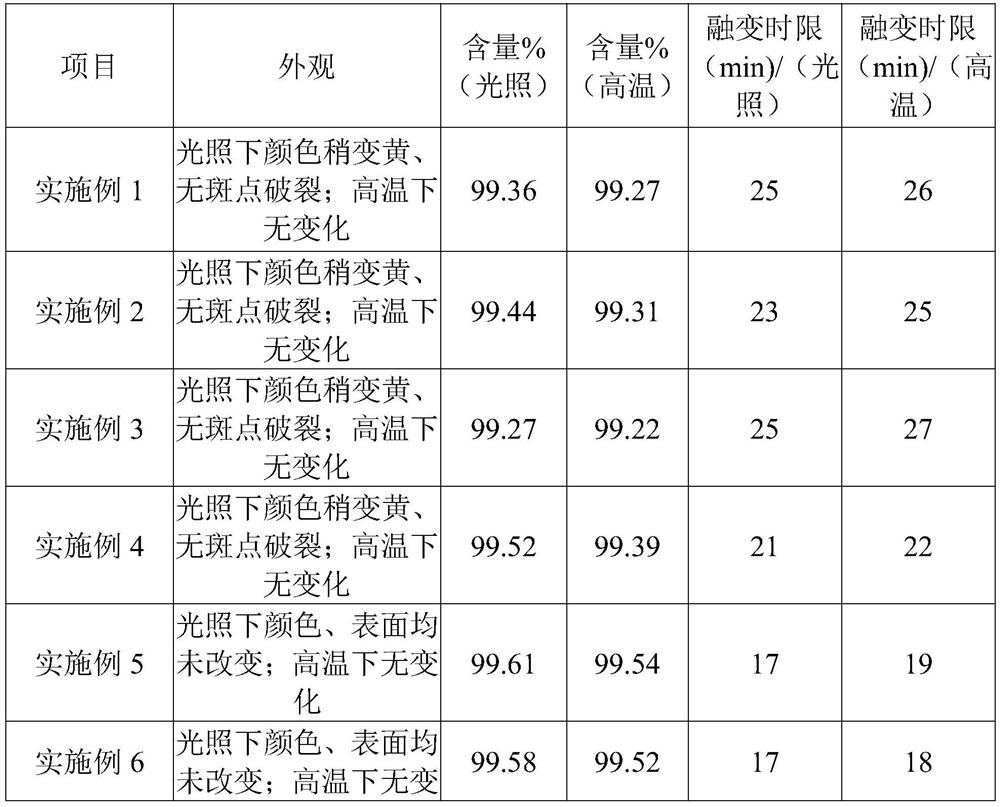

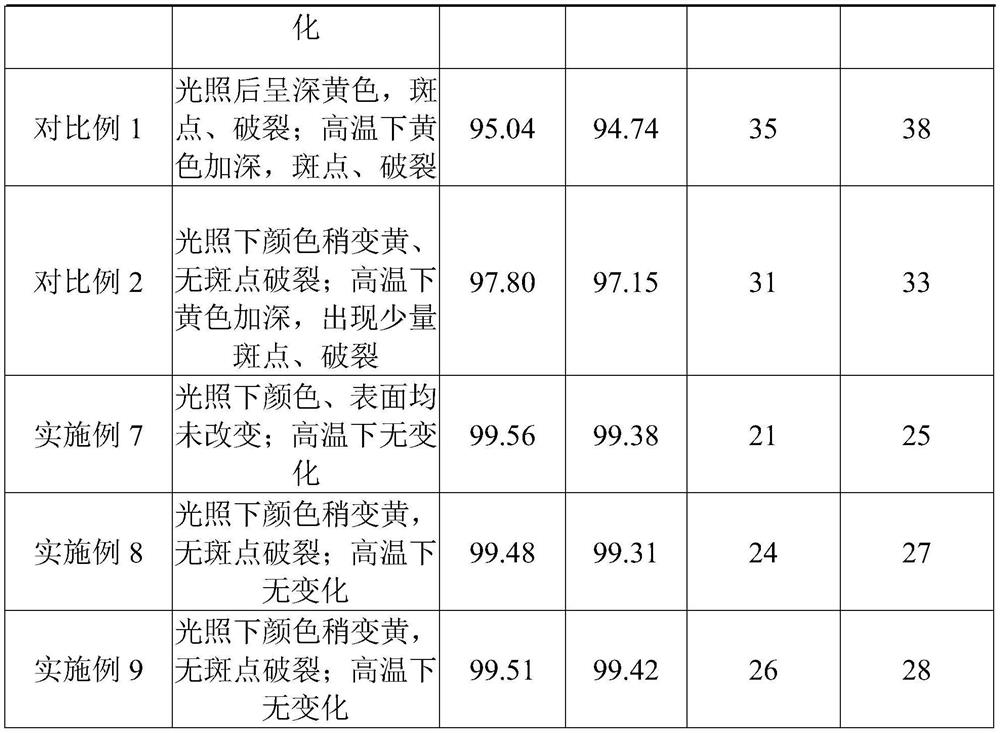

Examples

Embodiment 1-3

[0026] Sertaconazole nitrate suppository, according to the ratio of parts by weight, includes the raw material formula in the following table:

[0027] Component / g Example 1 Example 2 Example 3 Sertaconazole Nitrate 22.5 25 27.5 glycerin 2 3 4.5 Polysorbate 80 1 2 1 Laurocaprazine 2 3 5 Semi-synthetic fatty acid glycerides 166 169 170

[0028] The preparation method of above-mentioned sertaconazole nitrate suppository comprises the following steps:

[0029] Step 1: Grinding sertaconazole nitrate into fine powder, passing all through a 100-mesh sieve to obtain sertaconazole nitrate powder;

[0030] Step 2: Weigh and mix semi-synthetic fatty acid glycerides, glycerin, laurocapram and polysorbate 80 in proportion, and heat, melt and mix in a water bath at 45°C to obtain a mixed matrix;

[0031] Step 3: The sertaconazole nitrate powder is evenly dispersed in the mixed matrix, and ground for 1 hour, and mixed to obtain a s...

Embodiment 4

[0034] Sertaconazole nitrate suppository, including 25g of sertaconazole nitrate, 4g of glycerin, 802g of polysorbate, 4g of laurocapram and 168g of semi-synthetic fatty acid glyceride.

[0035] Its preparation method comprises the following steps:

[0036] Step 1: Grinding sertaconazole nitrate into fine powder, passing all through a 100-mesh sieve to obtain sertaconazole nitrate powder;

[0037] Step 2: Weigh semi-synthetic fatty acid glycerides, glycerin, laurocapram and polysorbate 80 respectively in proportion, first mix 80% of the quality of laurocapram and polysorbate 80 in a water bath at 60°C and heat, Stir and mix at 600r / min to obtain an organic mixture; then heat the remaining amount of laurocapram, semi-synthetic fatty acid glycerides, and glycerin in a water bath at 35°C, and stir and mix at 350r / min to obtain a matrix premix; finally The matrix premix and the organic mixture were heated and mixed at a constant temperature of 45°C under 850 r / min magnetic stirri...

Embodiment 5

[0041] The present embodiment is identical with each component consumption in embodiment 4, but preparation method is as follows:

[0042] Step 1: Grinding sertaconazole nitrate into fine powder, passing all through a 100-mesh sieve to obtain sertaconazole nitrate powder;

[0043] Step 2: Weigh semi-synthetic fatty acid glycerides, glycerin, laurocapram and polysorbate 80 respectively in proportion, first mix 80% of the quality of laurocapram and polysorbate 80 in a water bath at 60°C and heat, Stir and mix at 600r / min to obtain an organic mixture; then heat the remaining amount of laurocapram, semi-synthetic fatty acid glycerides, and glycerin in a water bath at 35°C, and stir and mix at 350r / min to obtain a matrix premix; finally The matrix pre-mixture and the organic mixture were heated and mixed at a constant temperature of 40°C under 850 r / min magnetic stirring, and kept warm for 5 minutes to obtain a mixed matrix;

[0044] Step 3: Keeping the temperature of the mixed ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com