Purification method of sertaconazole nitrate

A kind of technology of sertaconazole nitrate and purification method, applied in the field of purification of sertaconazole nitrate, can solve problems such as different melting points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0034] (1) 80kg purified water is added in the reaction kettle, open and stir, add 2.92kg sodium hydroxide while stirring, make it dissolve completely, obtain 3.6wt% sodium hydroxide solution, then add 10.4kg o-chlorothiophenol, stir at room temperature 30min; add 6.66kg of chloroacetone under stirring, and then stir for another 60min to react. Then add 21.36kg ether to extract the aqueous layer, and wash with water 3 times. The ether layer was collected in separate layers, combined with the oil layer and then distilled under reduced pressure to recover the ether to obtain 12.14 kg of o-chlorophenylthioacetone.

[0035] (2) Add 121.4kg of polyphosphoric acid in reactor A, stir, then add 12.14kg of o-chlorophenylthioacetone, heat up to 120°C and start to keep warm for 5 hours, and control the temperature at 120-140°C. Add water in another reaction kettle B, and cool down for later use. Release the reaction liquid in the reactor A, and slowly add it to another reactor B for di...

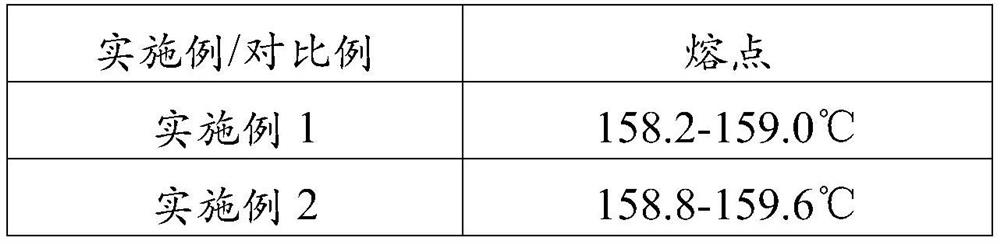

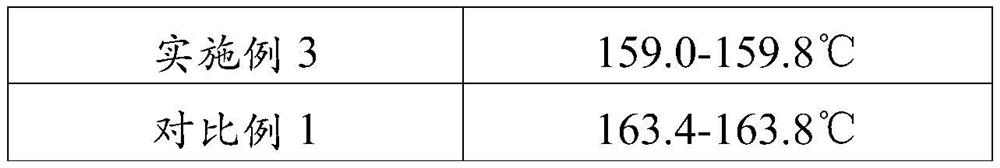

Embodiment 1

[0040] Add 60.63 g of 95% ethanol into the reaction flask, stir, heat, and raise the temperature to 60° C., add 23.04 g of crude sertaconazole nitrate while stirring, and heat up to reflux for 1 hour. Add activated carbon, reflux for 15 minutes, and filter the activated carbon while it is hot. The filtrate was added dropwise with 60.63 g of purified water under stirring, and crystals were precipitated. After the dropwise addition was completed, the mixture was stirred for another 30 minutes and filtered to obtain crystals. Dry in a vacuum oven to obtain 19.06 g of sertaconazole nitrate finished product.

Embodiment 2

[0042] The difference between embodiment 2 and embodiment 1 is that the consumption of 95% ethanol is 100g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com