Large carton paint mist treatment system and control method

A processing system and control method technology, applied in the field of large carton paint mist treatment system and control, can solve the problems of inconsistent exhaust resistance of carton filter modules, frequent replacement of consumables, low paint mist collection capacity, etc., to achieve overall The effect of high degree of automation, low consumption of consumables, and low frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

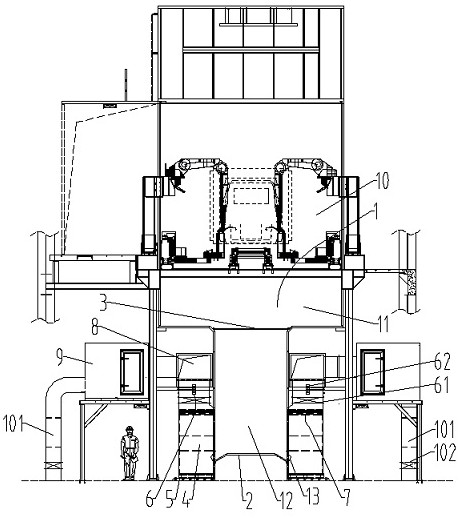

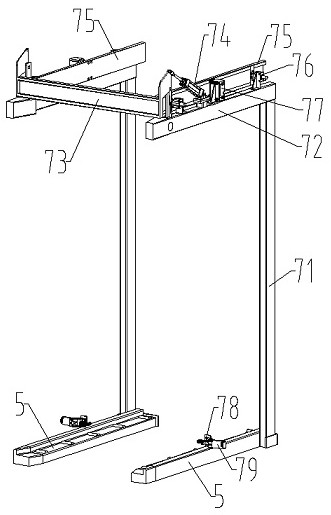

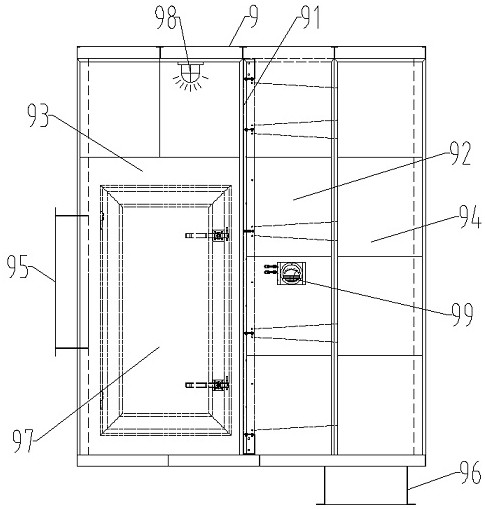

[0033] see Figure 1-4 , a large carton paint mist treatment system, located below the paint spray booth 10, including a T-shaped air guide chamber 1, the top of the T-shaped air guide chamber 1 communicates with the paint spray booth 10 through an air inlet, and the Both sides below the T-shaped air diversion chamber 1 are respectively provided with two groups of dry-type large carton groups, each group of dry-type large carton groups includes at least one dry-type large carton 4, and each dry-type large carton 4 is The clamping device 7 is used for fixed installation. The clamping device 7 is arranged on one side of the T-shaped air guiding chamber 1, and the side of the dry-type large paper box 4 close to the T-shaped air guiding chamber 1 passes through the air inlet. It communicates with the T-shaped air diversion chamber 1, and the top air outlet of each dry-type large paper box 4 is connected with an exhaust post-processing system through an upper exhaust pipe 8, and ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com