Coated lithium ion sieve and preparation method thereof

A lithium-ion, coated technology, which is applied in the field of coated lithium-ion sieve and its preparation, can solve the problems of low dissolution loss rate and poor adsorption performance, and achieve the solution of easy dissolution loss, good stability and easy industrialization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a coated lithium ion sieve, comprising the steps of:

[0029] S01: MnCO 3 Calcined in air atmosphere for 5h to obtain Mn 2 o 3 ;

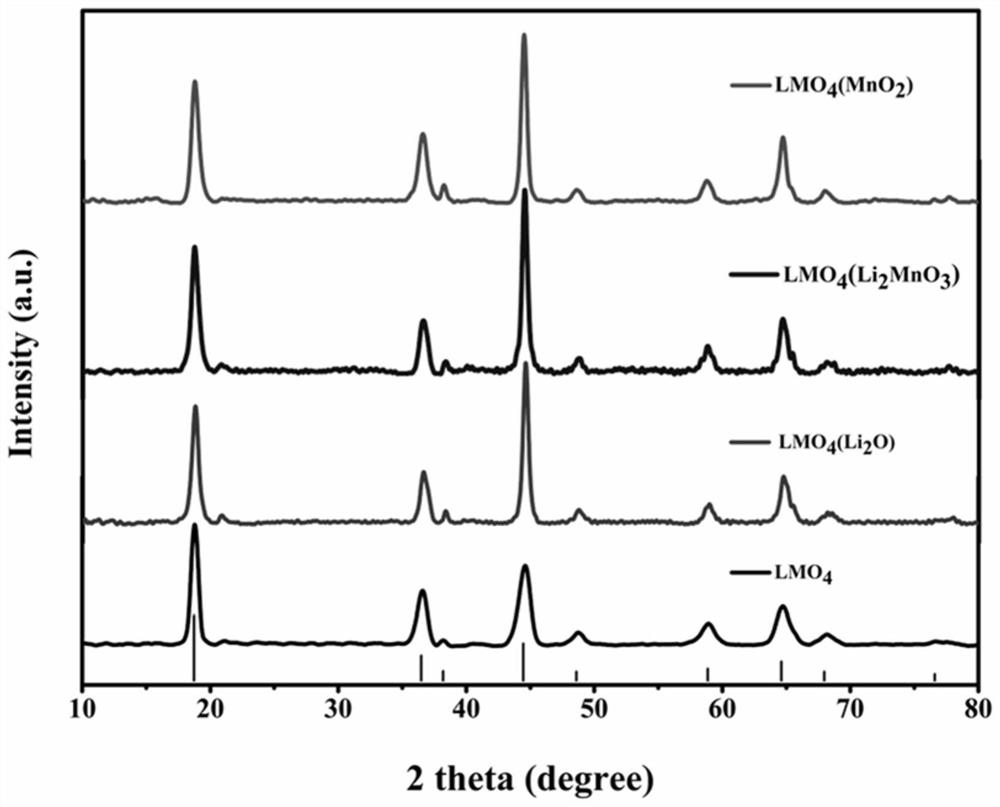

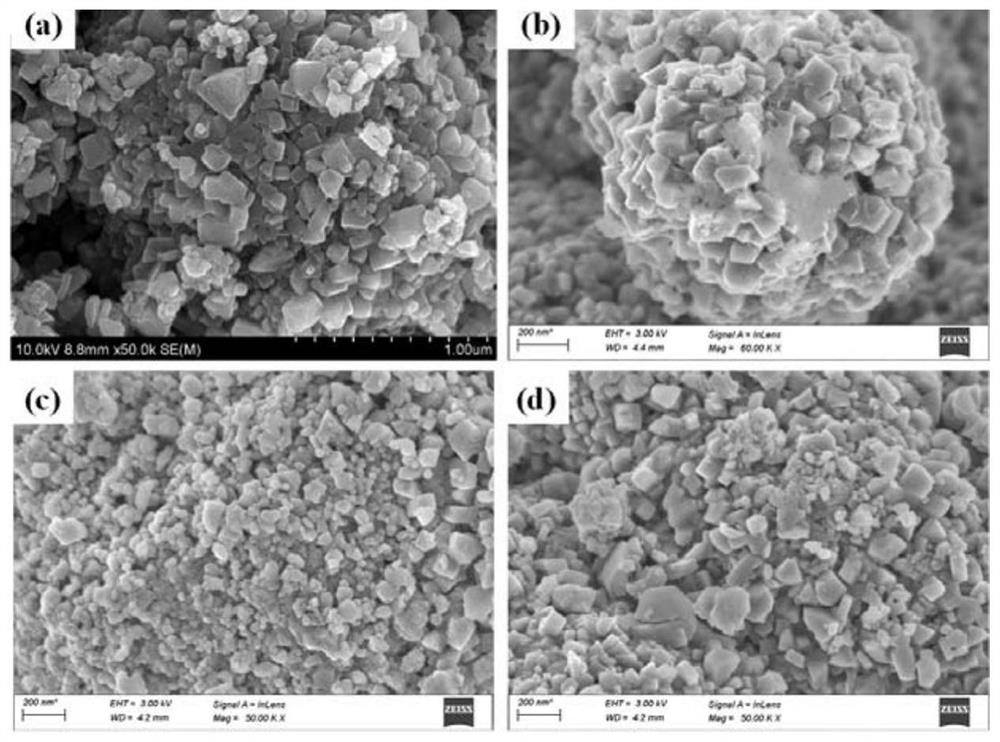

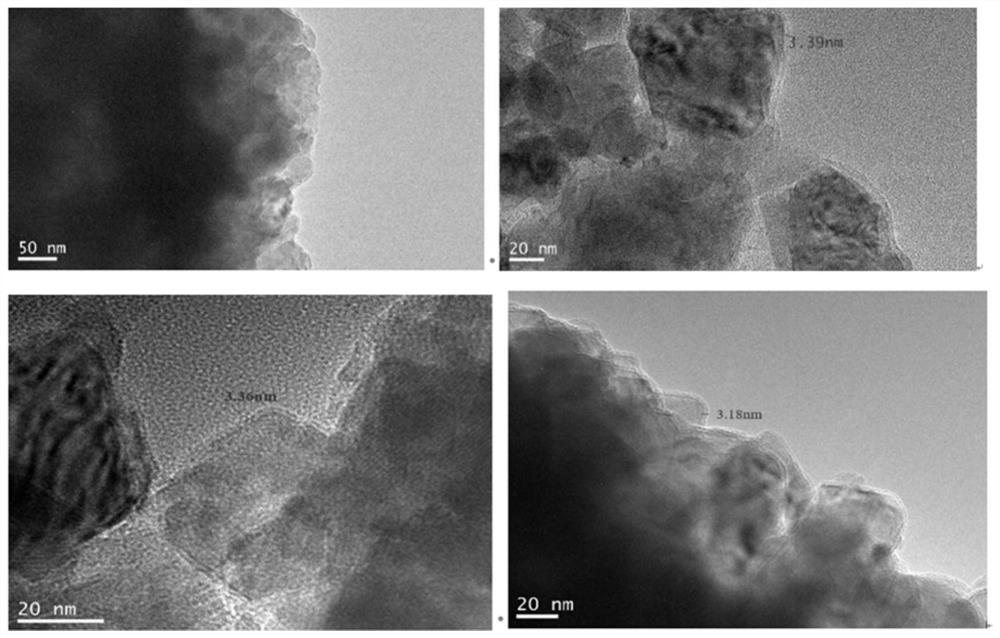

[0030] S02: Mn 2 o 3 Mix and grind with lithium salt, transfer to a 100mL polytetrafluoroethylene-lined stainless steel reaction kettle, put the reaction kettle in an oven, and carry out hydrothermal reaction at a reaction temperature of 120°C, and the reaction time is 48h; after the reaction is completed , put the obtained product into an oven and dry at 60°C for 12h to obtain the product LiMnO 2 ; Among them, Mn 2 o 3 The molar ratio of Li / Mn in lithium salt is 1:1;

[0031]It is worth noting that the actual amount of lithium salt used is 1.00-1.05 times of its theoretical amount. This is because the required precursor product can be obtained by one calcination, and the loss of lithium salt is small, so the amount of lithium salt can be increased. The theoretical amount or slightly excessive amount is adopte...

Embodiment 2

[0039] A method for preparing a coated lithium ion sieve, comprising the steps of:

[0040] S01: MnCO 3 Calcined under air atmosphere for 2h to obtain Mn 2 o 3 ;

[0041] S02: Mn 2 o 3 Mix and grind with lithium salt, transfer to a 100mL polytetrafluoroethylene-lined stainless steel reaction kettle, put the reaction kettle into an oven, and carry out hydrothermal reaction at a reaction temperature of 120°C for a reaction time of 36 hours; after the reaction is completed , put the obtained product into an oven and dry at 60°C for 12h to obtain the product LiMnO 2 ; Among them, Mn 2 o 3 The molar ratio of Li / Mn in lithium salt is 10:1;

[0042] S03: Add 1g LiMnO to 4M lithium nitrate solution 2 Ultrasound for 2 hours, and dry at 60°C for 36 hours. After the dried powder is fully mixed in the grinding process, put it into a crucible and place it in a muffle furnace. The phase reaction was 2h, and the oxide-coated Li 1.6 mn 1.6 o 4 Lithium ion adsorbent; among them, t...

Embodiment 3

[0045] A method for preparing a coated lithium ion sieve, comprising the steps of:

[0046] S01: MnCO 3 Calcined under air atmosphere for 10h to obtain Mn 2 o 3 ;

[0047] S02: Mn 2 o 3 Mix and grind with lithium salt, transfer to a 100mL polytetrafluoroethylene-lined stainless steel reaction kettle, put the reaction kettle in an oven, and carry out hydrothermal reaction at a reaction temperature of 200°C, and the reaction time is 72h; after the reaction is completed , put the obtained product into an oven and dry at 60°C for 12h to obtain the product LiMnO 2 ; Among them, Mn 2 o 3 The molar ratio of Li / Mn in lithium salt is 5:1;

[0048] S03: Add 1g LiMnO to 4M manganese nitrate solution 2 Ultrasound for 10 hours, and dry at 60°C for 36 hours. After the dried powder is fully mixed in the grinding process, it is put into a crucible and placed in a muffle furnace. Phase reaction for 10 h yielded oxide-coated Li 1.6 mn 1.6 o 4 Lithium ion adsorbent; among them, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com