A doped modified lithium ion sieve and its preparation method and application

A lithium ion, modified technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of lithium recovery rate less than 1%, decreased adsorption capacity, low adsorption capacity, etc. Achieve the effect of maintaining cycle stability, small average particle size, and strong universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

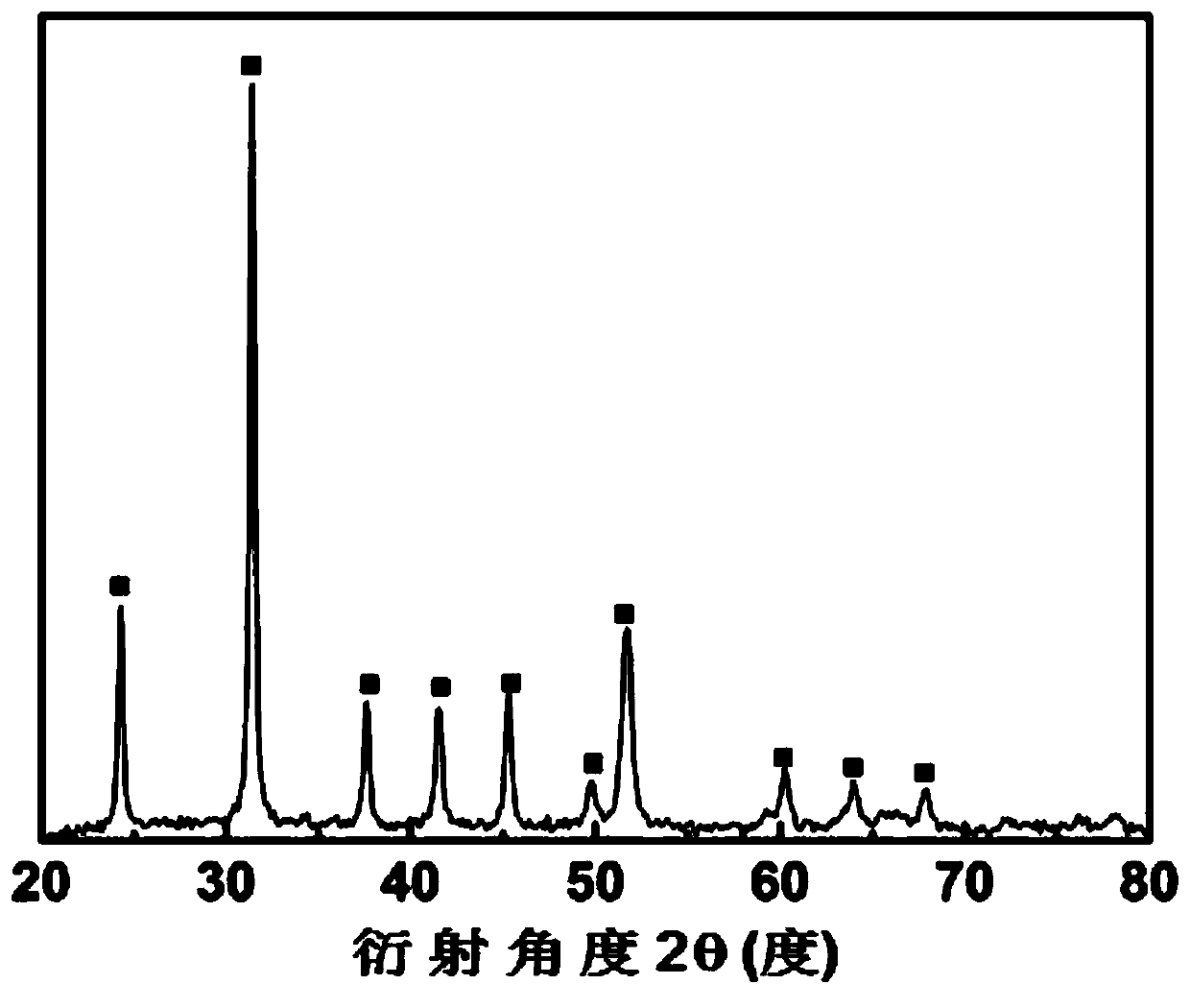

[0034] A nickel-doped modified HMn 2 o 4 The preparation method of lithium ion sieve comprises the following steps:

[0035] (1) 12.2g manganese acetate tetrahydrate, 0.124g nickel acetate tetrahydrate, 30.0g urea and 20.0g polyethylene glycol were added to 1000ml deionized water, stirred and mixed evenly to obtain a dark red transparent mixed solution;

[0036] (2) Transfer the mixed solution obtained in step (1) to a 1.5L polytetrafluoroethylene-lined stainless steel reactor, put the reactor into a homogeneous reactor, and perform a hydrothermal reaction at a reaction temperature of 180°C , the reaction time is 12h; after the reaction is finished, the obtained product is washed and then put into a vacuum drying oven and dried at 60°C for 12h to obtain nickel-doped manganese carbonate;

[0037] (3) get 2.87g by the nickel-doped manganese carbonate that step (2) obtains, weigh lithium carbonate 0.95g, after fully mixing in grinding, put into crucible and place in muffle furn...

Embodiment 2

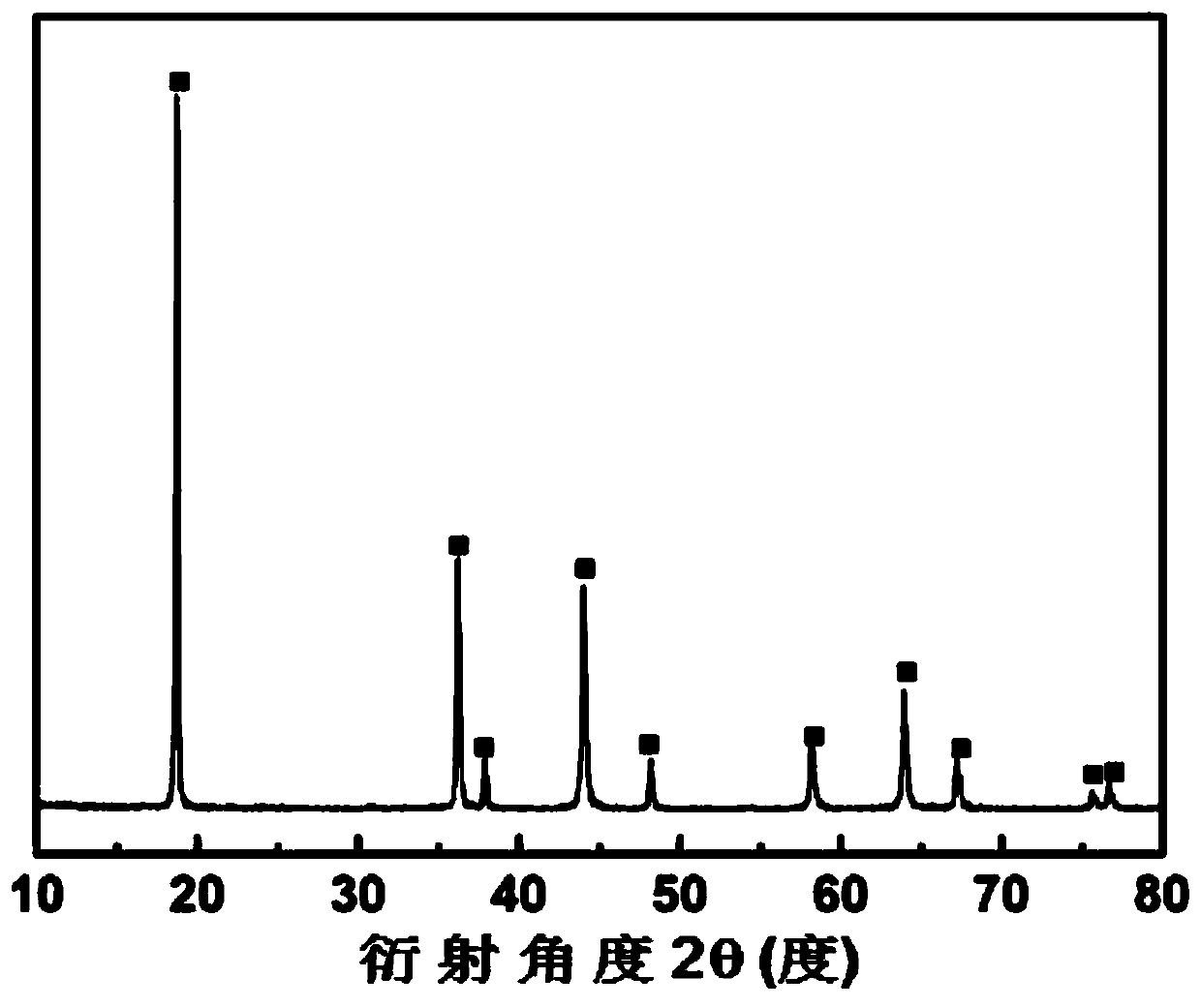

[0043] A kind of cobalt-doped modified HMn 2 o 4 The preparation method of lithium ion sieve comprises the following steps:

[0044] (1) 12.67g manganese sulfate monohydrate, 0.649g anhydrous cobalt sulfate, 10.0g urea and 5.0g polyethylene glycol were added to 1000ml deionized water, stirred and mixed evenly to obtain a dark red transparent mixed solution;

[0045] (2) Transfer the mixed solution obtained in step (1) to a 1.5L polytetrafluoroethylene-lined stainless steel reactor, put the reactor into a homogeneous reactor, and perform a hydrothermal reaction at a reaction temperature of 190°C , the reaction time is 8h; after the reaction is finished, the obtained product is washed and placed in a vacuum drying oven at 60°C for 12h to obtain cobalt-doped manganese carbonate;

[0046] (3) 2.87g is taken by the cobalt-doped manganese carbonate that step (2) obtains, weigh lithium carbonate 0.92g, after fully mixing in grinding, put into crucible and place in muffle furnace, i...

Embodiment 3

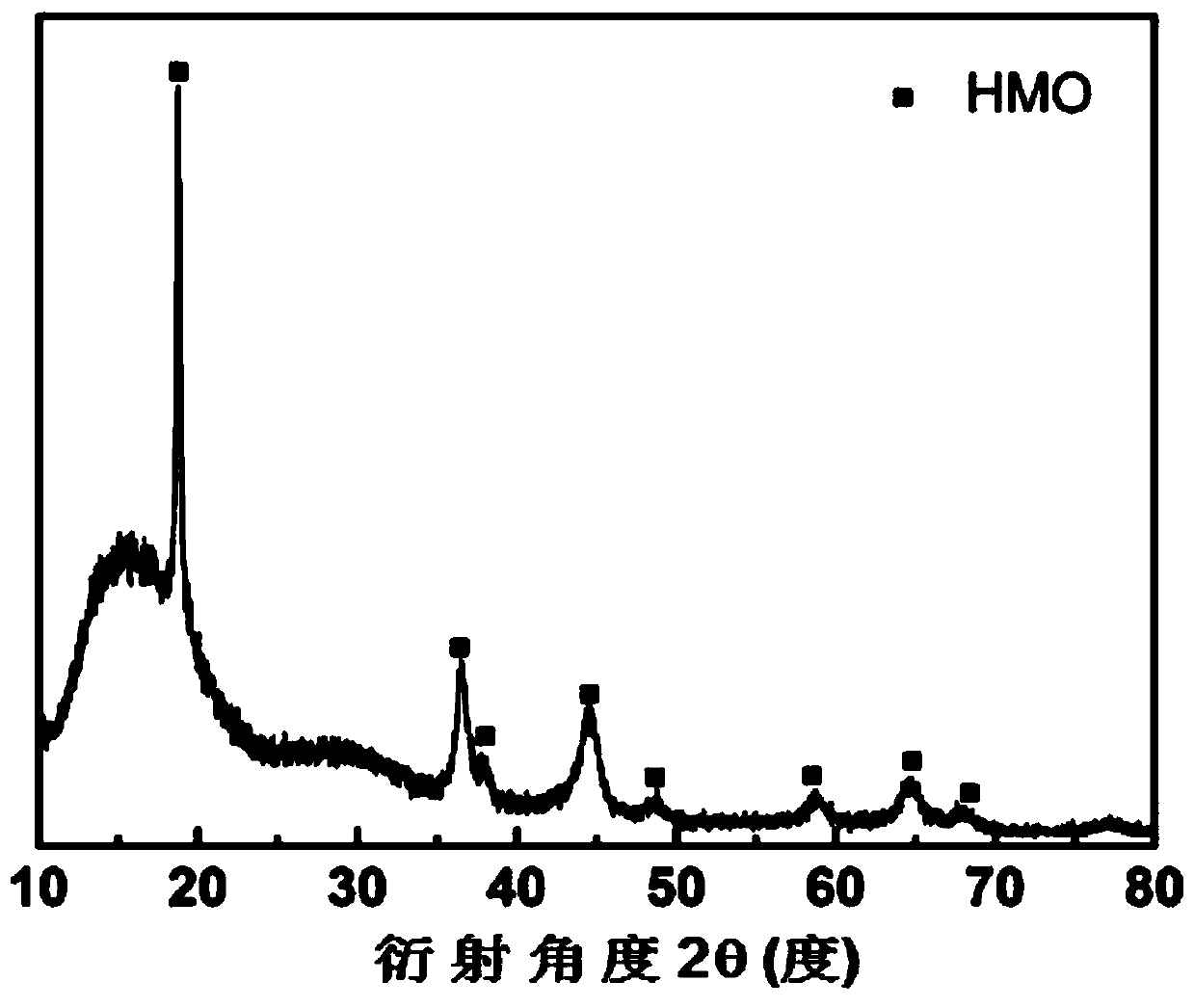

[0052] A nickel-doped modified HMn 2 o 4 The preparation method of lithium ion sieve comprises the following steps:

[0053] (1) 12.58g anhydrous manganese chloride, 0.26g anhydrous nickel chloride, 20.0g urea and 10.0g polyethylene glycol are added to 1000ml deionized water, stirred and mixed evenly to obtain a dark red transparent mixed solution;

[0054] (2) Transfer the mixed solution obtained in step (1) to a 1.5L polytetrafluoroethylene-lined stainless steel reactor, put the reactor into a homogeneous reactor, and perform a hydrothermal reaction at a reaction temperature of 150°C , the reaction time is 12h; after the reaction is finished, the obtained product is washed and then put into a vacuum drying oven and dried at 60°C for 12h to obtain nickel-doped manganese carbonate;

[0055] (3) the nickel-doped manganese carbonate that step (2) obtains is got 2.87g, weighs lithium carbonate 0.96g, after fully mixing in grinding, puts into crucible and places muffle furnace, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com