A method and device for generating a single longitudinal columnar grain weld

A columnar crystal, vertical technology, used in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of inability to generate, single, poor performance of transverse columnar crystal welds, reduce transverse grain boundaries, improve mechanical properties, The effect of improving direction consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

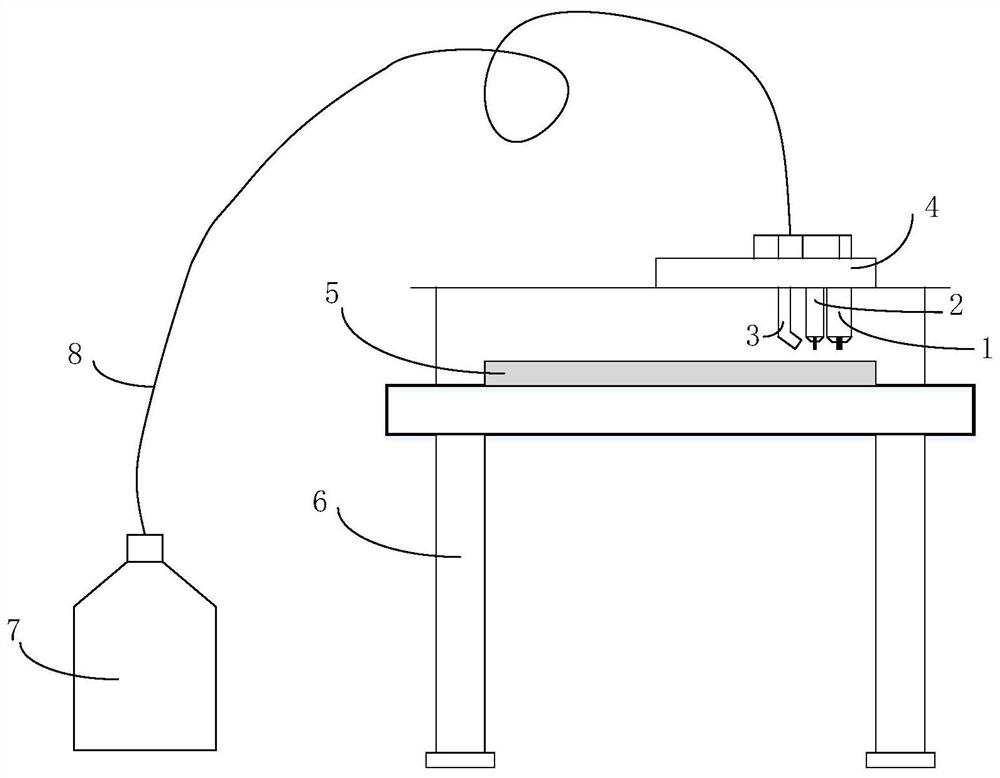

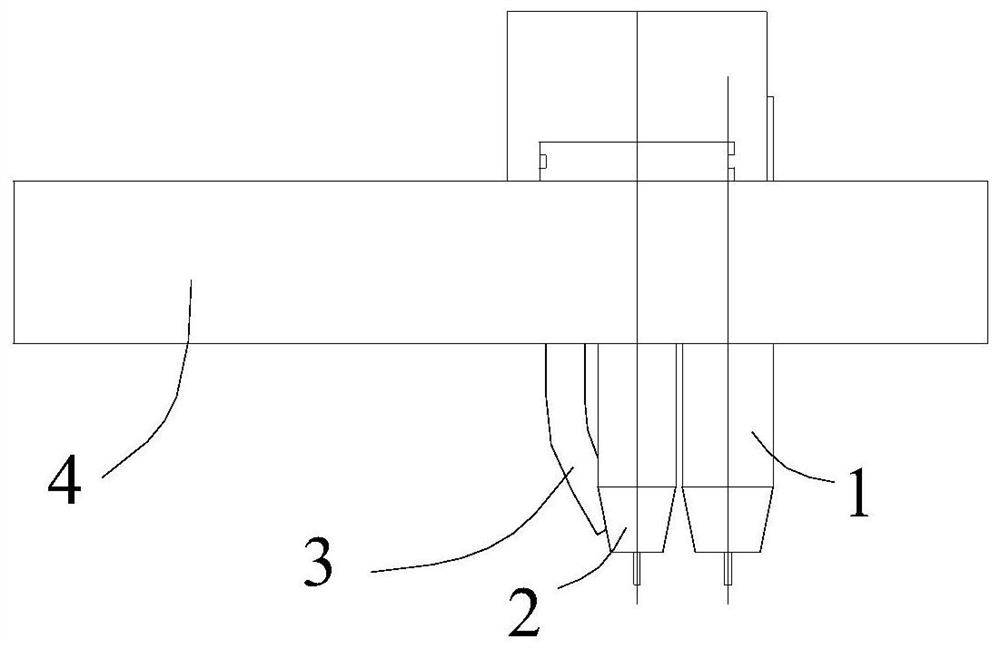

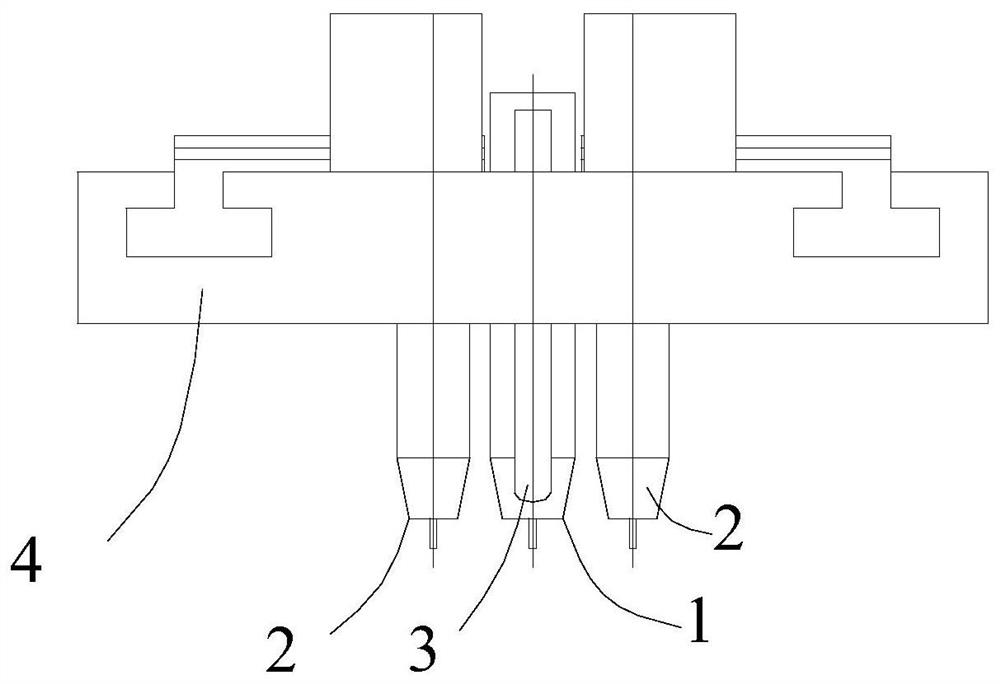

[0072] Such as figure 1 As shown, the single longitudinal columnar grain welding seam welding device in this embodiment includes: main welding torch 1, auxiliary welding torch 2, cold source nozzle 3, welding torch clamping tool 4, weldment 5, weldment clamping tooling 6, liquid nitrogen tank 7. Connecting pipe 8.

[0073] The main welding gun 1, the auxiliary welding gun 2 and the cold source nozzle 3 are connected with the welding gun clamping tool 4, wherein the main welding gun 1 is fixed on the front end (welding direction) of the welding gun clamping tool 4, and the cold source nozzle 3 is clamped on the front of the main welding gun. Rear, and link to each other with liquid nitrogen tank 7 by connecting pipe 8. Two auxiliary heat source welding torches 2 are located obliquely behind the main welding torch, and are clamped symmetrically. The relative position of the auxiliary welding torch 2 and the cold source nozzle 3 relative to the main welding torch 1 can be moved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com