Connecting structure and connecting method of chrome-molybdenum steel and low-carbon steel for pressure vessel

A technology of pressure vessel and connection structure, which is applied in the field of dissimilar steel connection for pressure vessels, and can solve problems such as strength damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

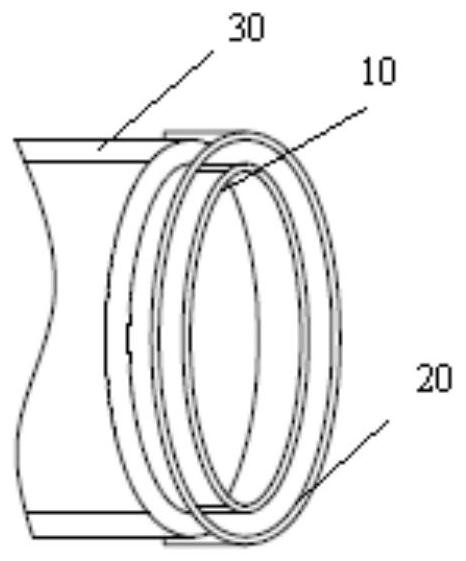

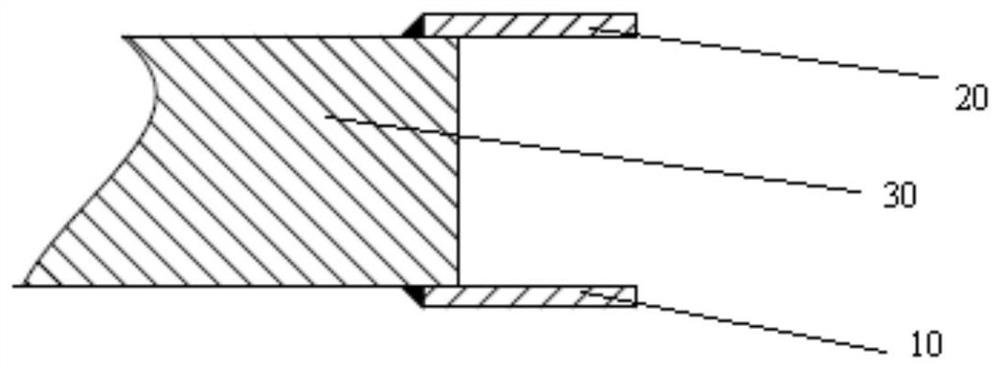

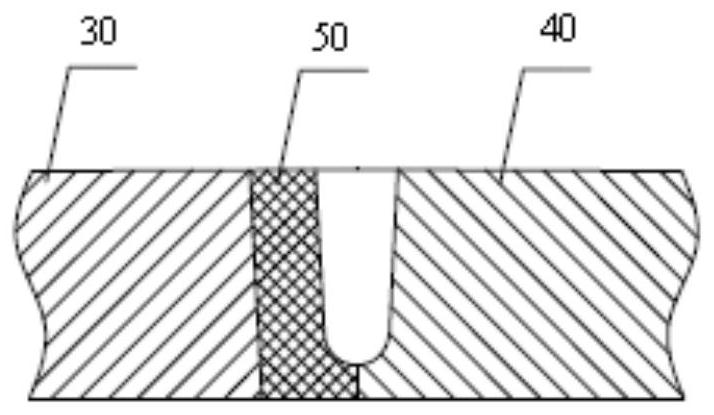

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0022] As recorded in the background technology, when 12Cr2Mo1R high-strength chrome-molybdenum steel is used on one side and low-carbon steel is used on the other side, the welding of ultra-thick circumferential welded joints with chrome-molybdenum steel on one side and Q345R on the other side occurs The structural form and the choice of welding method will directly affect the quality of the product. The choice of welding groove and welding process are the key steps of this welding. Due to the different base metals on both sides, the required heat treatment system has a large deviation. When manufacturing threaded locking ring heat exchangers: 12Cr2Mo1R material and its welded parts need to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com