3D rough surface geomembrane production device and method

A production device and production method technology, applied in the direction of 3D object support structure, manufacturing tools, additive processing, etc., can solve the problem that the rough surface of the membrane body cannot meet the engineering needs, and achieve controllable rough surface density, uniform roughness height, The effect of controllable rough area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

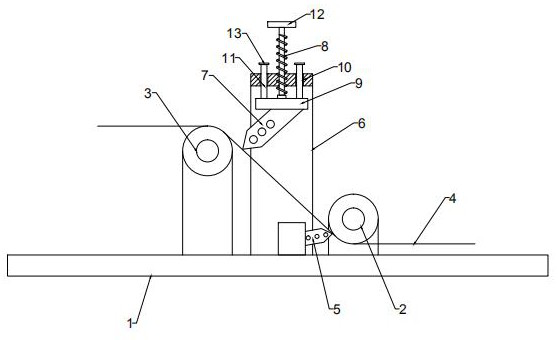

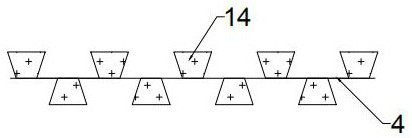

[0029] Embodiment: The geomembrane body 4 passes through the first fixed roller 2 and the second fixed roller 3 successively, and the adjusting hand wheel 12 is turned to make the screw 8 drive the adjusting plate 9 and the second 3D printing head 7 to descend, so that the second 3D printing head 7 is close to The geomembrane body 4, through the first 3D printing head 5 and the second 3D printing head 7, set the height and shape of the rough surface 14 according to the predetermined printer program. The surface of the film body 4, and the rough surface 14 can be controlled as a single rough surface 14, and can also be controlled as a double rough surface 14, which solves the problem that the film elongation of the rough surface 14 is low, and the elongation rate is too low to reach 600%. And it can realize rough surface 14 in the geomembrane production line, and the production is stable. According to the width of the geomembrane, multiple printing heads can be arranged side by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com