Cleaning mechanism and cleaning device

A cleaning mechanism and cleaning water technology, applied in printing machines, general parts of printing machinery, printing, etc., can solve problems such as deformation of the spray rod, unequal distance from the spray hole to the cleaning cloth roll, inconsistent water volume and water pressure, etc. Achieve the effect of maintaining constant distance, uniform cleaning water and uniform water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment describes the cleaning mechanism of the present invention in detail.

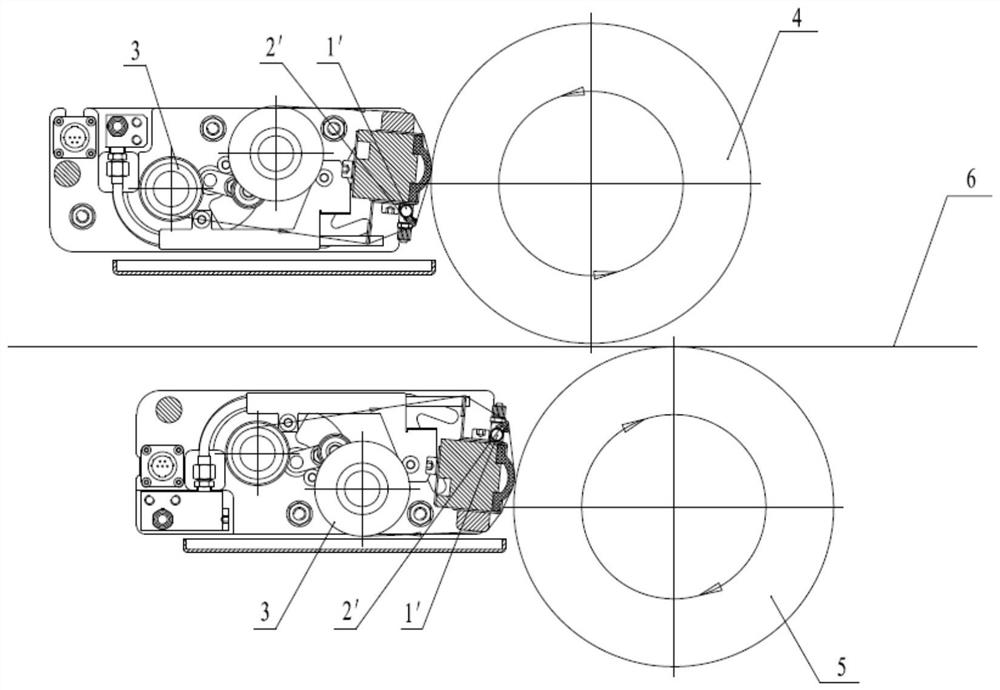

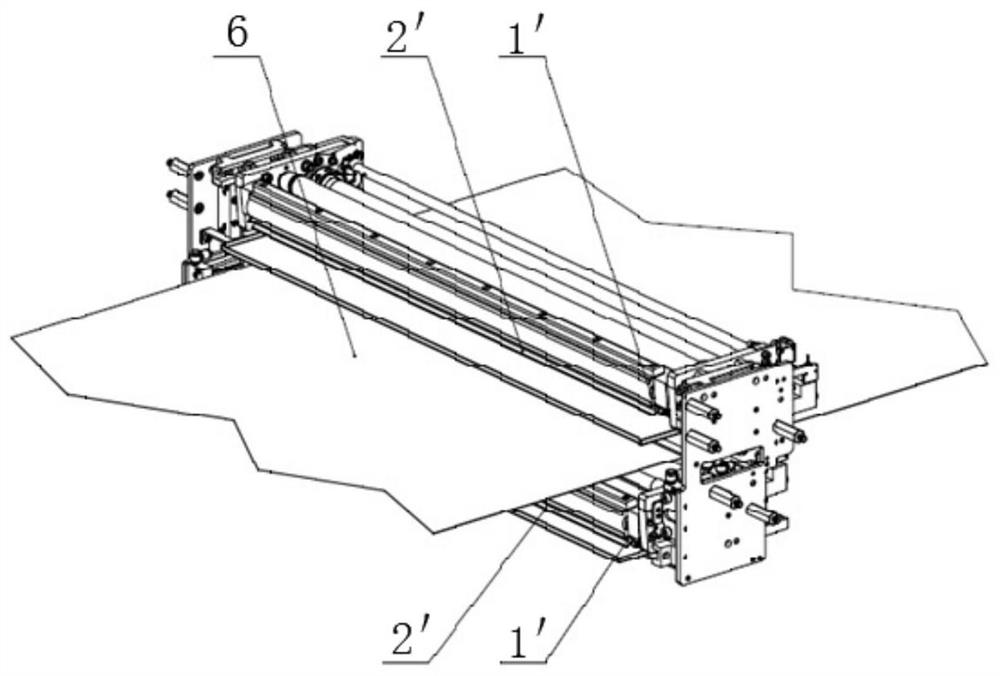

[0043] The cleaning mechanism of this embodiment comprises a water pipe assembly, a water spray assembly and a cloth roll 3 for cleaning, such as Figure 7 or 8. Among them, the water pipe assembly is used for the circulation of cleaning water. There are multiple groups of water spray assemblies arranged in series on the water pipe assembly. keep constant. Preferably, the water spray assembly includes a solenoid valve 21 and a shower head 22, the solenoid valve 21 and the shower head 22 are connected in series, the solenoid valve 21 is used to control the working state of the shower head 22, and the shower head 22 has at least a water spray state or a non-water spray state, such as Figure 7 or 8.

[0044] In the cleaning mechanism of this embodiment, the water pipe assembly is used for the circulation of cleaning water, and multiple groups of water spray assemblies are arranged in...

Embodiment 2

[0060] This embodiment describes the cleaning device of the present invention in detail.

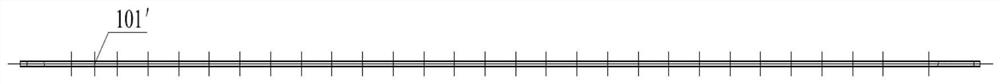

[0061] The cleaning device of this embodiment includes the cleaning mechanism of any technical solution in Embodiment 1, such as Figure 7shown. The cleaning device of this embodiment has the cleaning mechanism of any one of the technical solutions in Embodiment 1, so that the cleaning device of this embodiment has the ability to keep the distance between the water spray assembly and the cleaning cloth roll 3 constant, each water spray assembly The sprayed cleaning water has the advantages of uniform water volume and constant water pressure. That is, the cleaning device of this embodiment solves the problem that the spray rod 1' is easily deformed in the prior art, resulting in the unequal distance from the spray hole 101' to the cleaning cloth roll 3, and the spraying holes 101' on the spray rod 1'. The technical problem of inconsistent water volume and water pressure.

[0062] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com