Low-carbon-residue insulating layer material for electronic control solid propellant electrode and preparation method thereof

A solid propellant and insulating layer technology, applied in the field of solid propellant electrode materials, can solve problems such as high carbon residue rate and affect the use of new energy, achieve high burning rate and reduce surface attachments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

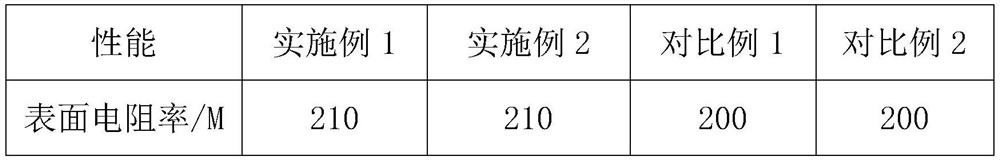

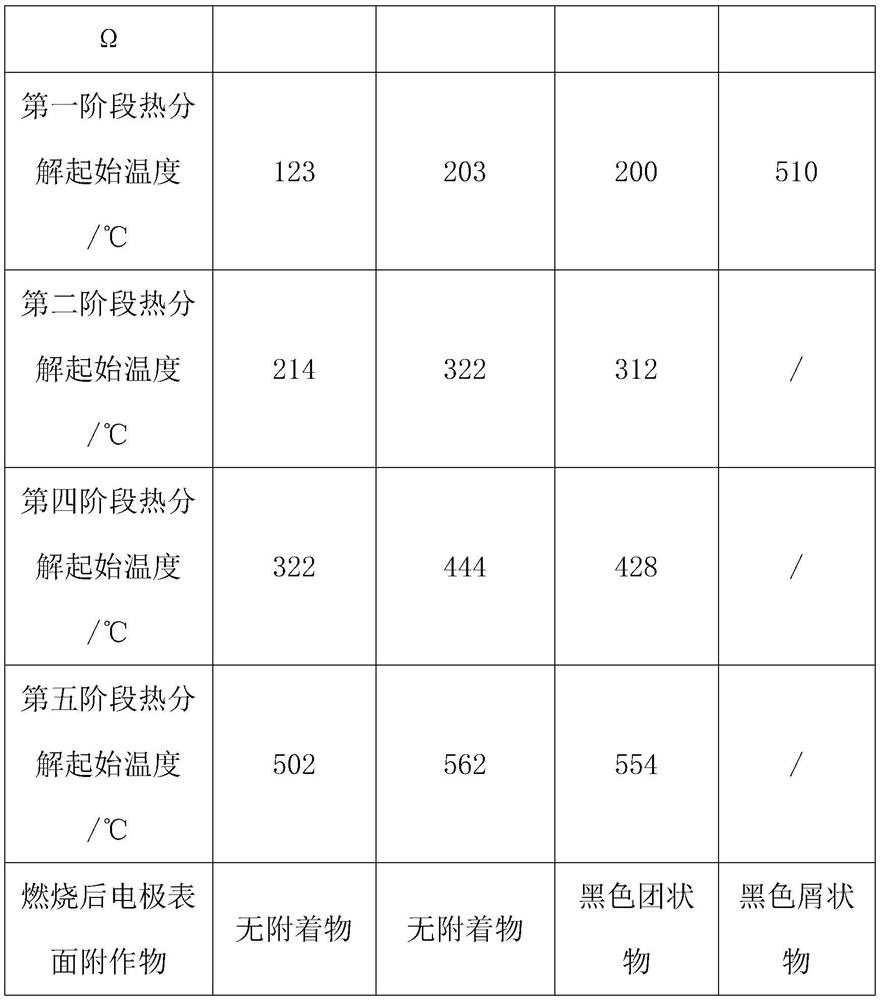

Embodiment 1

[0043] A low carbon residue insulating layer material for an electrically controlled solid propellant electrode and a preparation method thereof, comprising the following raw materials and mass fractions:

[0044] Polypropylene: 60;

[0045] Dicumyl peroxide: 1;

[0046] Rosin: 10;

[0047] Polyethylene wax: 1;

[0048] White carbon black: 20;

[0049] PPS: 8;

[0050] Stir the weighed raw materials of each component in a high-speed mixer for 3 minutes, and then put the mixed material into a twin-screw extruder for extrusion and granulation. The temperature in the second zone is 140-160°C, the temperature in the third zone is 150-170°C, the temperature in the fourth zone is 170-180°C, the temperature in the fifth zone is 170-190°C, the temperature in the sixth zone is 170-190°C, and the temperature of the machine head is 160-180°C. The host speed is 180~300r / min. The extruded granules are dried, crushed and ground, and passed through a 120-mesh sieve. Put the sieved pow...

Embodiment 2

[0052] A low carbon residue insulating layer material for an electrically controlled solid propellant electrode and a preparation method thereof, comprising the following raw materials and mass fractions:

[0053] Polypropylene: 80;

[0054] Di-tert-butyl peroxide: 2.0;

[0055] Petroleum resin: 3;

[0056] Polyethylene wax: 2;

[0057] White carbon black: 8;

[0058] PEEK: 5;

[0059] Stir the weighed raw materials of each component in a high-speed mixer for 3 minutes, and then put the mixed material into a twin-screw extruder for extrusion and granulation. The temperature in the second zone is 140-160°C, the temperature in the third zone is 150-170°C, the temperature in the fourth zone is 170-180°C, the temperature in the fifth zone is 170-190°C, the temperature in the sixth zone is 170-190°C, and the temperature of the machine head is 160-180°C. The host speed is 180~300r / min. The extruded granules are dried, crushed and ground, and passed through a 120-mesh sieve. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com