Cold-rolled steel sheet for lampshade and production method of cold-rolled steel sheet

A technology of cold-rolled steel sheet and production method, which is applied in metal rolling, metal rolling, workpiece cooling device, etc., can solve the problems of unstable material performance and high manufacturing cost, and can solve the problem of uneven performance, low manufacturing cost, and satisfying Effects of performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

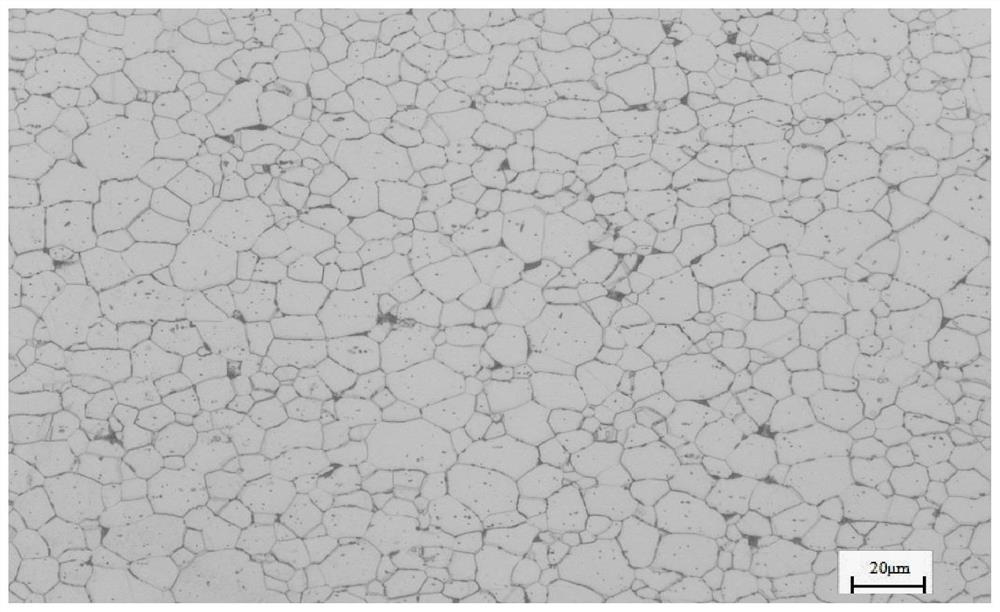

Image

Examples

Embodiment Construction

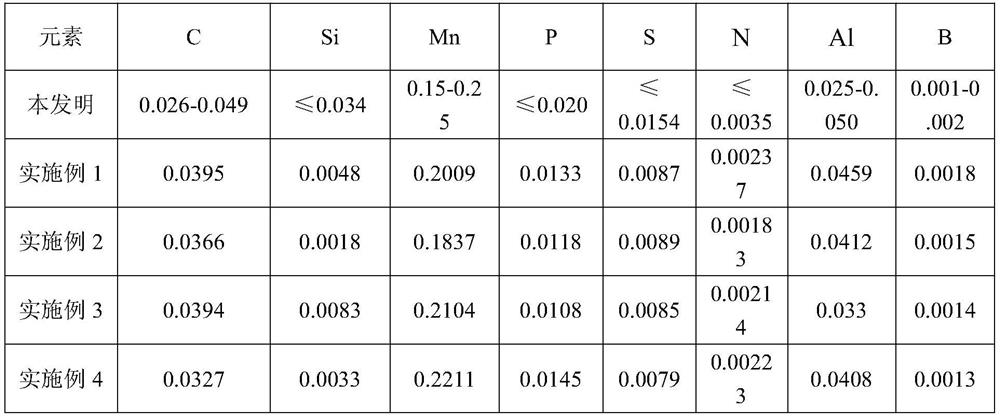

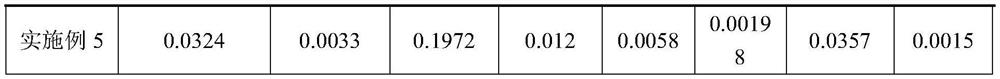

[0043] The present invention will be further described below in conjunction with specific examples 1-5, as shown in Table 1-4, Table 1 is the chemical composition (by weight percentage) of the steel of the embodiment of the present invention, and the balance is Fe and unavoidable impurities.

[0044] Table 1 Chemical composition of the steel of the embodiment of the present invention, unit: weight percent.

[0045]

[0046]

[0047] The molten steel that meets the basic requirements of the chemical composition is obtained through converter smelting. After the molten steel is desulfurized in the LF ladle refining furnace and the alloy composition is fine-tuned, it is poured by the continuous casting machine to obtain the continuous casting slab; the thickness of the slab is 210-230mm, and the width is 900-1400mm , the length is 8500-11000mm.

[0048] The cut-to-length slab produced by steelmaking is directly sent to the heating furnace for reheating, and then sent to the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap