Pre-reinforcement structure for construction of underground diaphragm wall in alluvial layer and construction method

A technology of underground diaphragm wall and construction method, which is applied in basic structure engineering, excavation, sheet pile wall, etc., can solve the problems of loss of solid wall slurry, instability and collapse of hole wall, easy collapse of groove wall, etc., so as to improve the work efficiency of groove formation. , Speed up the construction progress and avoid the effect of wall collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

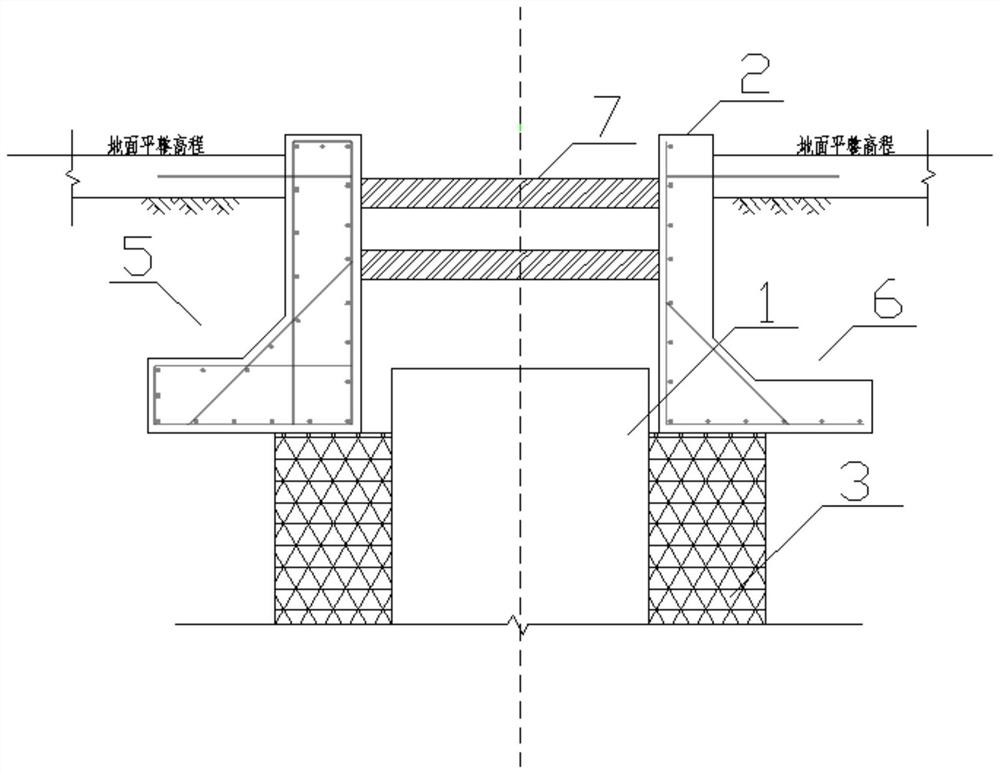

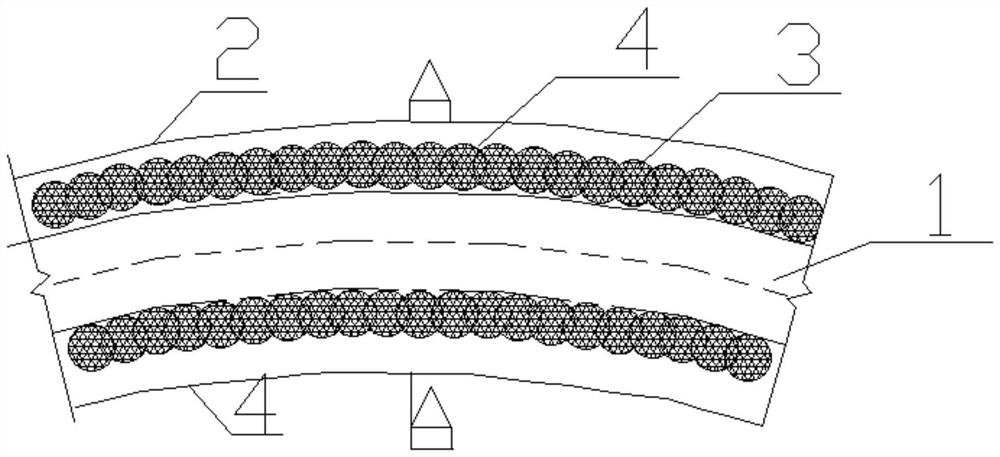

[0036] The present invention provides a pre-reinforcement structure for construction of an underground diaphragm wall in the alluvial layer, comprising an underground diaphragm wall 1 and a guide wall 2 arranged oppositely along the axis of the underground diaphragm wall 1 , and a number of uniform walls are arranged below the guide wall 2 along the central axis of the guide wall 2 . The dense closed pile row 3 is provided, and the dense closed pile row 3 is poured integrally with the guide wall 2, and several of the dense closed pile row 3 form a pile row wall 4.

[0037] When this embodiment is used, the integrated construction of the densely enclosed row of piles 3 and the guide wall 2 can effectively reinforce weak land, and at the same time, ensure that the displacement of the guide wall 2 meets the design requirements. The formation of the pile wall 4 can reduce the internal force of the support structure, avoid the horizontal displacement of the guide wall 2, ground subs...

Embodiment 2

[0048] A method for constructing a pre-reinforced structure of an underground diaphragm wall in an alluvial layer, comprising the following steps:

[0049] A. Stratum prediction and reinforcement depth determination; according to the design geological exploration data, carefully analyze the physical and chemical properties of different stratum soils in the construction area, and aim at the thixotropic and rheological clay layers with a liquid index greater than 1.0. The sandy soil layer with groundwater, and the pebble stratum area with rich, connected and highly permeable groundwater are pre-reinforced. The reinforcement depth is determined according to the depth of the above-mentioned unfavorable geology, and the construction parameters are implemented after field tests.

[0050] B. Technical preparations; including being familiar with and reviewing drawings and related design documents, understanding and implementing design intentions; mastering stratum structure, soil layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com