Three-stage pressure reducing valve

A pressure reducing valve and pressure reducing chamber technology, applied in the field of pressure reducing valves, can solve the problems of high labor intensity, difficult maintenance, affecting the effect of secondary and tertiary decompression, etc., to reduce damage and increase the range of applicable temperature difference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

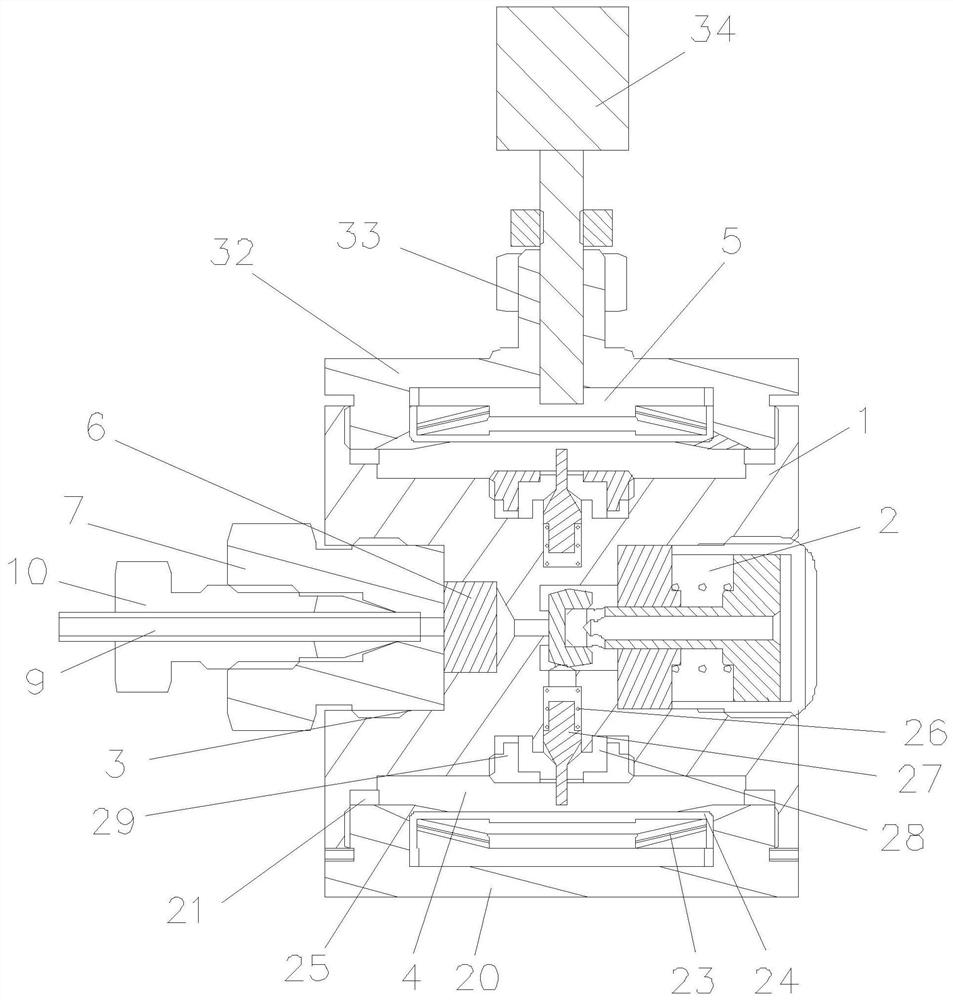

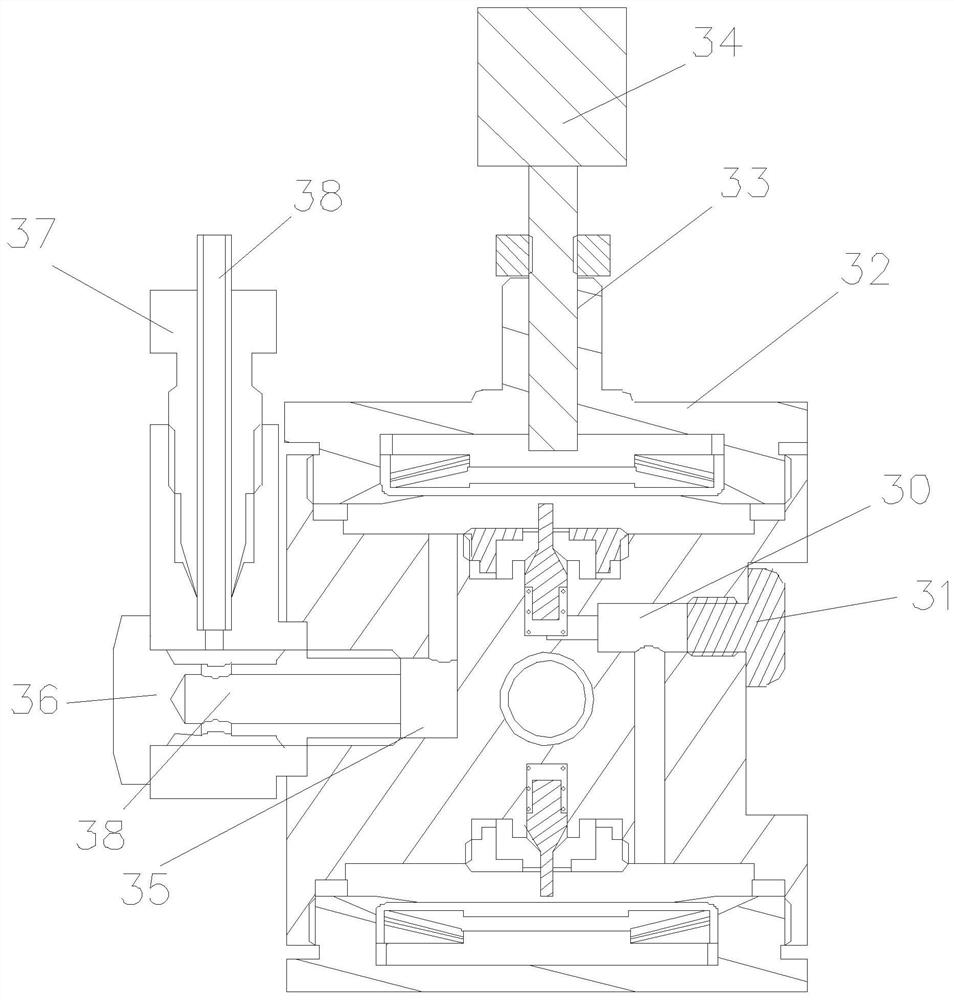

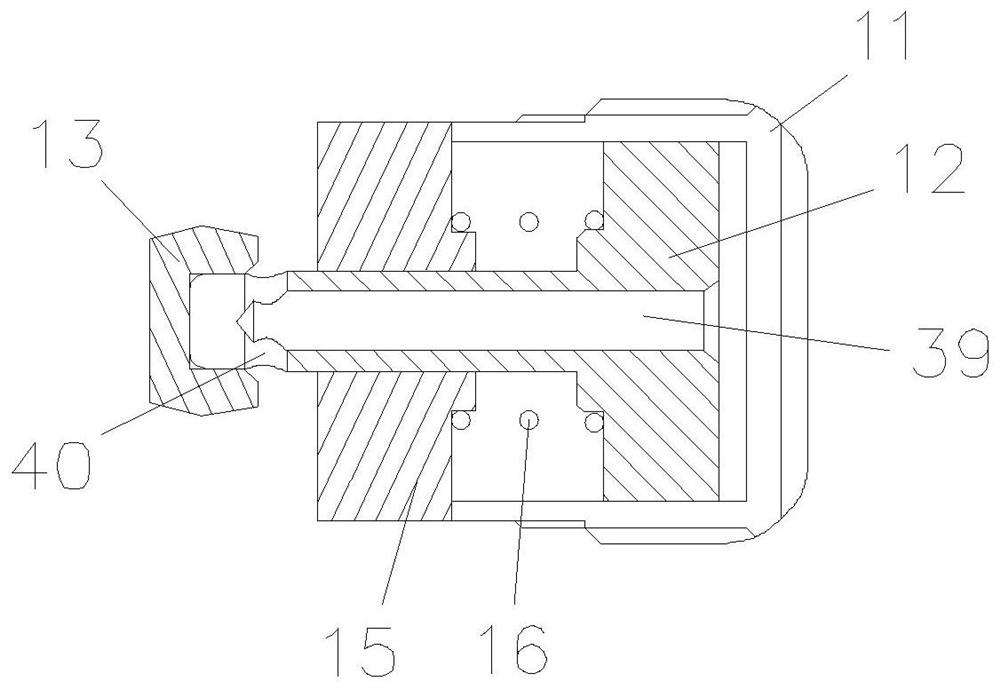

[0017] Embodiment: a kind of three-stage decompression valve, such as Figure 1-Figure 3 As shown, 1. includes a valve body 1, characterized in that: the right end of the valve body 1 is provided with a first-stage decompression chamber 2, and the left side of the valve body 1 is provided with an air intake hole 3, and the valve body 1 The lower end of the valve body 1 is provided with a secondary decompression chamber 4, and the upper end of the valve body 1 is provided with a tertiary decompression chamber 5, and the inlet port 3 communicates with the primary decompression chamber 2, and the primary decompression chamber 2 communicates with the secondary decompression chamber 4, and the bottom end of the air intake hole 3 is provided with a filter element 6, and the primary decompression chamber 2 is fixedly connected with a compression nut 11 through threads, and the compression nut The inside of 11 is slidingly equipped with a piston rod 12, the right end of the piston rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com