On-line production control system and steps of row drilling

A technology of production control and monitoring equipment, which is applied in the direction of electrical program control and sequence/logic controller program control, etc., which can solve the problems of poor speed information transmission and disturbance function, weakening speed information transmission performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The embodiments of the present invention will be further described below with reference to the embodiments.

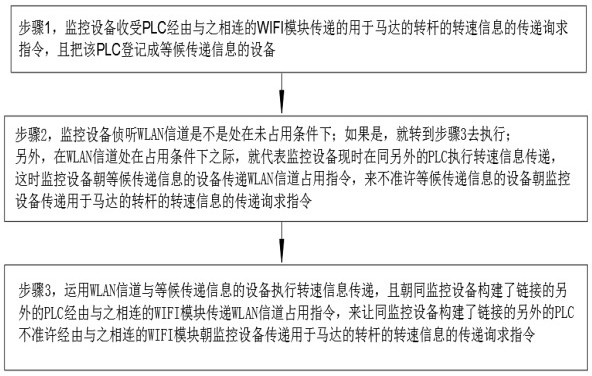

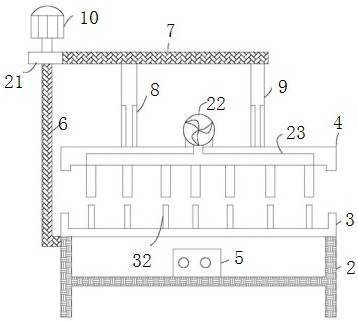

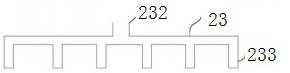

[0071] like Figure 1-Figure 5 As shown in the figure, the steps of the row drilling on-line production control system include:

[0072] At present, the transmission of rotational speed information has a poor function of releasing disturbances. To reduce the disturbance when another PLC transmits rotational speed information via the WIFI module connected to it, the capacity of the information frame of rotational speed information should be as low as possible. In this way, the probability of error in the transmission of speed information is reduced, so that the capacity of the information frame in this information transmission mode is restricted; in addition, when several PLCs transmit speed information synchronously through the WIFI module connected to it, Under the condition of overlapping bandwidth, the rotational speed information will disturb each other dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com