Sweet potato greenhouse temperature and humidity control device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

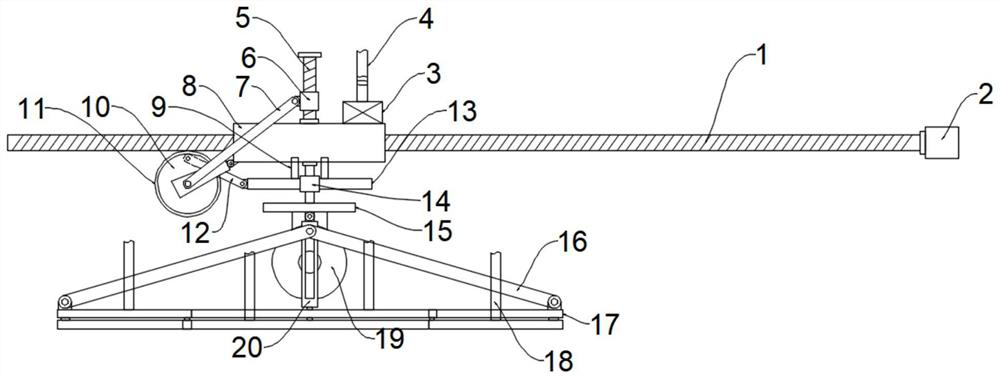

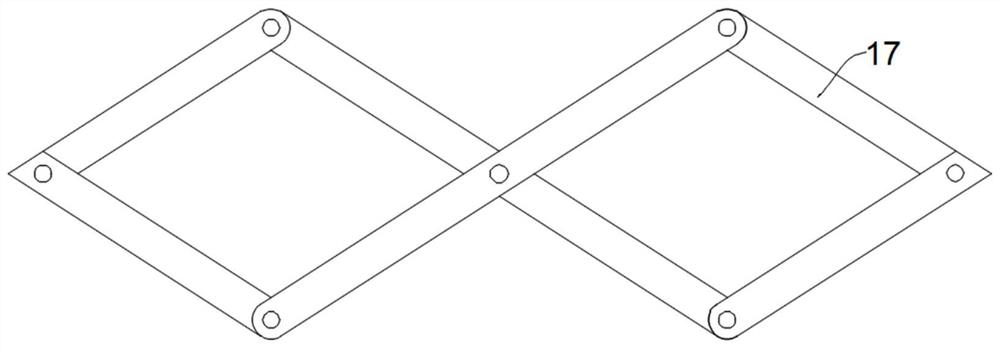

[0021] see Figure 1~2 , in an embodiment of the present invention, a sweet potato greenhouse temperature and humidity control device, which is installed on the top of the greenhouse, including a mounting base 8, a feed mechanism for driving the mounting base 8 to move, and a control unit installed on the mounting base 8, In this embodiment, the feed mechanism includes a threaded rod 1 that is rotatably installed on the top of the greenhouse, a first motor 2 for fixing the rotation of the threaded rod 1, and a guide rod that guides the mounting seat 8. The control unit includes Mounting plate 15, a drive mechanism for driving the mounting plate 15 to rotate forward and backward alternately, and an air outlet assembly mounted on the lower surface of the mounting plate 15, the mounting plate 15 is mounted on the lower surface of the mounting seat 8 through a mounting shaft and a bearing to drive The mechanism drives and connects the mounting shaft. In this embodiment, the drivin...

Embodiment 2

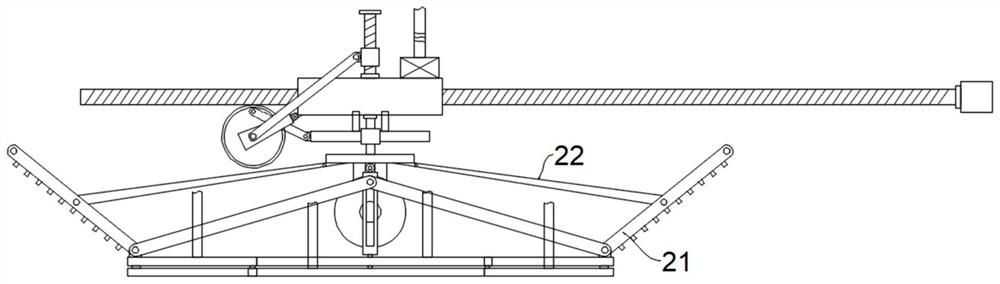

[0024] see image 3The difference between this embodiment of the present invention and Embodiment 1 is that, further, support rods 22 are hingedly mounted on both sides of the mounting plate 15, and the end of the support rod 22 away from the mounting plate 15 is rotatably mounted with a side tube 21. One end of the pipe 21 is hinged with the third connecting rod 16, and the side pipe 21 is connected with the air distribution pipe 18, and the outside of the side pipe 21 is uniformly provided with nozzles, and blowing air is blown to both sides through the setting of the side pipe 21, while the third connecting rod 16 moves to drive The swing of the side pipe 21 can further increase the blowing range and improve the control efficiency.

[0025] The working principle of the present invention is: when working, the temperature detector or the humidity detector monitors the temperature and humidity in the greenhouse, and when the preset value is exceeded, the fan 3 can be used to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com