Supported mercury-free catalyst, preparation method thereof and application of supported mercury-free catalyst in preparation of vinyl chloride through ethyne hydrochlorination

A mercury catalyst and a supported technology are applied in the field of supported mercury-free catalysts and their preparation to achieve the effects of reducing pollution and potential safety hazards and having good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

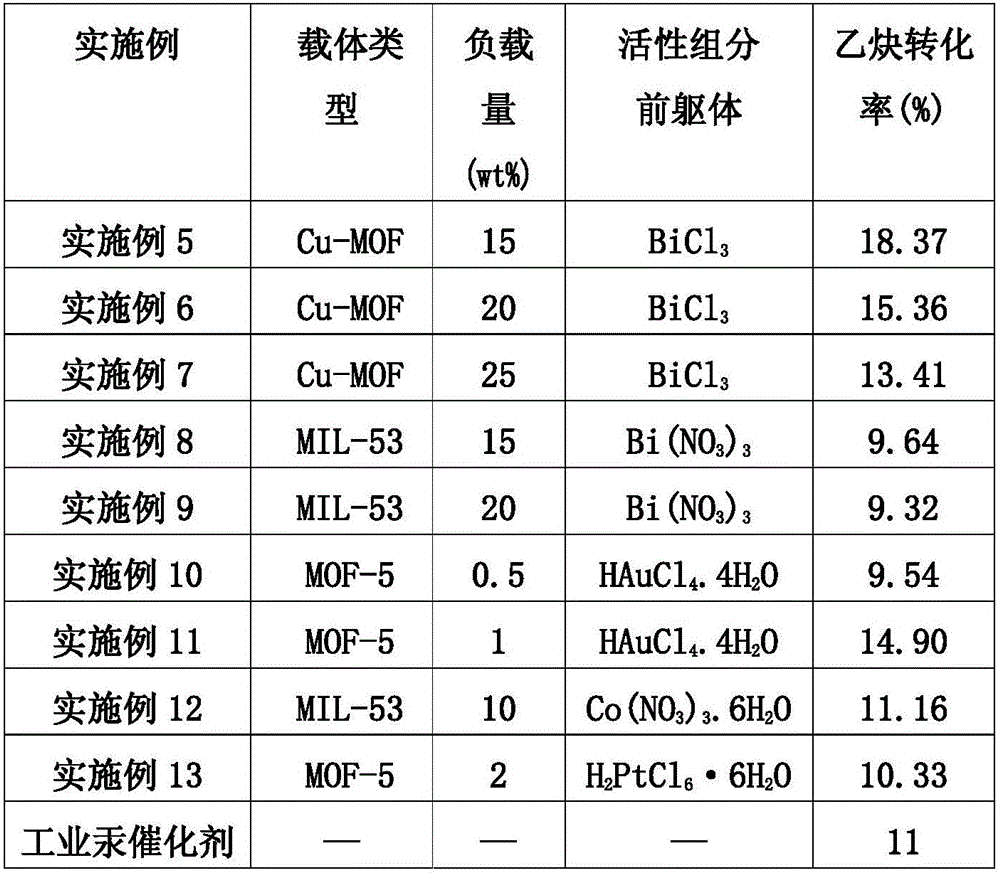

Examples

Embodiment 1

[0021] Embodiment 1, this load-type mercury-free catalyst obtains by following preparation method: the first step, the chloride of active component or the nitrate of active component or the sulfate of active component or the phosphate of active component are used After the solvent is dissolved, the precursor solution of the active component is obtained; in the second step, the metal-organic framework porous material is added to the precursor solution of the active component for impregnation according to the equal-volume impregnation method or the over-volume impregnation method, and after impregnation, it is dried, After calcining and tableting under the protection of nitrogen, a supported mercury-free catalyst is obtained. Metal-organic framework porous materials are currently known and public. Metal-organic framework porous materials include MOF-5, HKUST-1, UIO series, ZIF series, MIL series, IRMOF series and MOF-53, etc.; metal-organic framework porous materials can use solv...

Embodiment 2

[0022] Embodiment 2, as the optimization of above-mentioned embodiment, active component is Bi or Cu or Sn or Co or Au or Pd or Pt or Ru or Ir or wherein more than one; Or / and, active in the load-type mercury-free catalyst The mass percentage loading of the components is 0.5% to 30%.

Embodiment 3

[0023]Example 3, as an optimization of the above example, the solvent is deionized water or acetonitrile; or / and, the metal organic framework porous material and the precursor solution of the active component are mixed in a volume ratio of 1:1 to 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com