Multi-stage controllable progressive energy-absorbing lattice structure

A lattice structure and endpoint technology, applied in special data processing applications, instruments, geometric CAD, etc., can solve the problems of inability to protect, reduce the initial strength and stiffness of energy-absorbing structures, and high loads of protected objects with initial strength and stiffness, and achieve The effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific structure and implementation process of this solution will be described in detail below through specific embodiments and accompanying drawings.

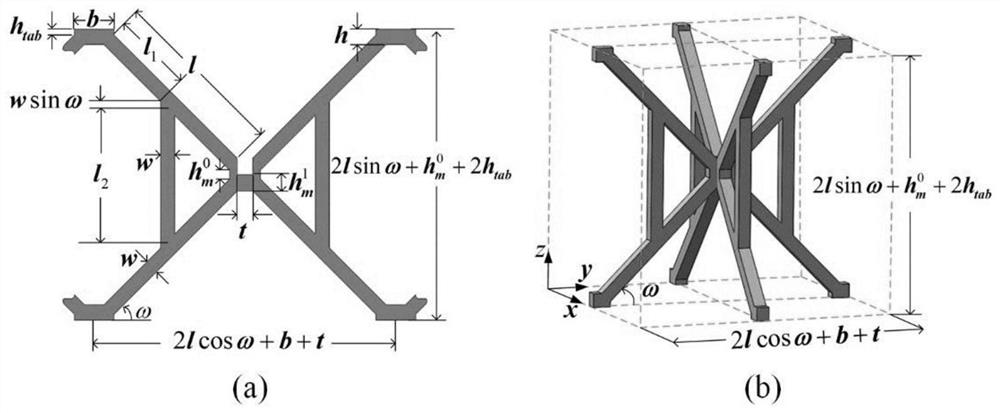

[0033] Such as figure 1 As shown, in one embodiment of the present invention, a multi-level controllable progressive energy-absorbing lattice structure is disclosed, including spliced rods, and a unit cell structure and a lattice structure composed of spliced rods.

[0034] The splicing rod includes two X-shaped orthogonally connected oblique rods, vertical rods connecting the two oblique rods are respectively arranged on the opposite sides in the horizontal direction of the connection point of the two oblique rods, and the connection positions of the two vertical rods correspond to each other and parallel to each other; that is, the vertical bars are only symmetrically arranged on opposite sides of the oblique bars, and the overall shape is a butterfly-shaped two-dimensional pattern.

[0035] The unit cell s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com