Concrete production management system

A production management system and production management technology, applied in the field of concrete production management system, can solve problems such as high error rate and large data connection workload, and achieve the effect of reducing error rate, reducing manual workload, and facilitating query and file retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the purpose, technical solutions and advantages of this application clearer, the following in conjunction with the attached Figure 1-9 And embodiment, this application is described in further detail. It should be understood that the specific embodiments described here are only used to explain the present application, not to limit the present application.

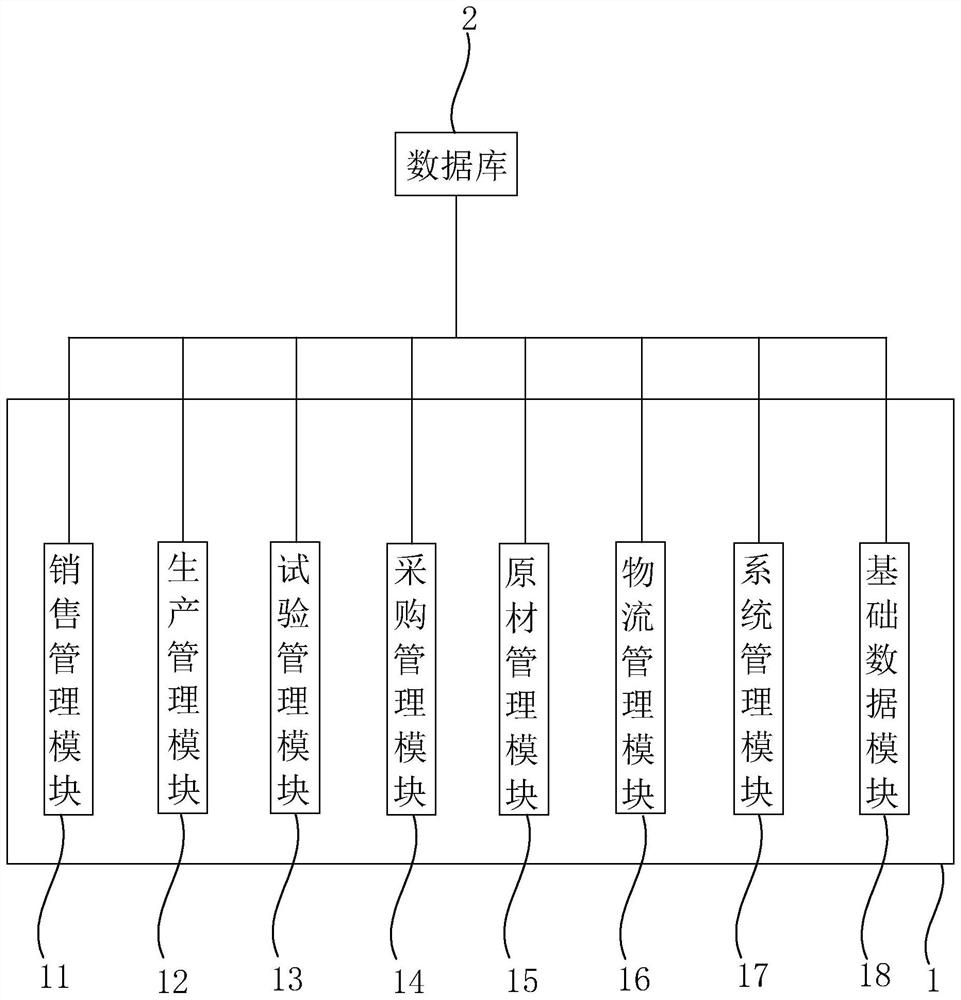

[0047] The embodiment of the present application discloses a concrete production management system. refer to figure 1 , a concrete production management system includes a system interface 1 and a database 2, the system interface 1 includes a sales management module 11, a production management module 12, a test management module 13, a procurement management module 14, a raw material management module 15, a logistics management module 16, System management module 17 and basic data module 18; database 2, used to store sales management module 11, production management module 12, test management module ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap