High-precision synchronous motor

A high-precision synchronous and casing technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of high-precision synchronous motors that cannot meet the assembly accuracy requirements of the casing, and the high defective rate of casings and end covers , Low coordination between the motor cover plate and the casing, to achieve the effects of improving stability and reliability, easy promotion, and guaranteed concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

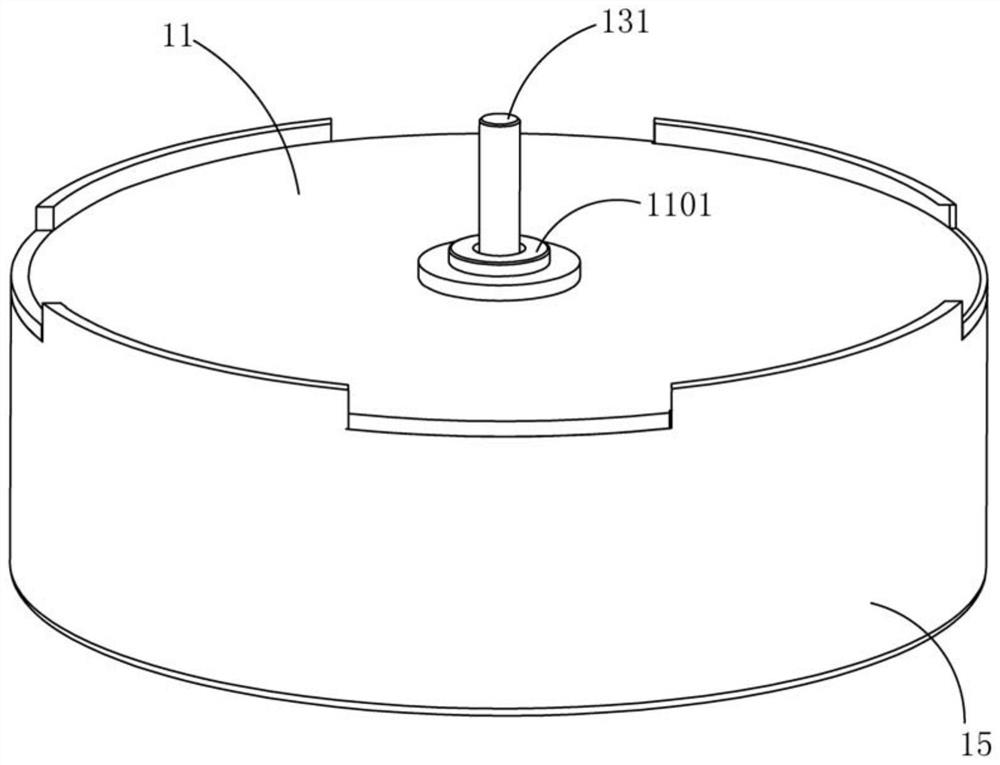

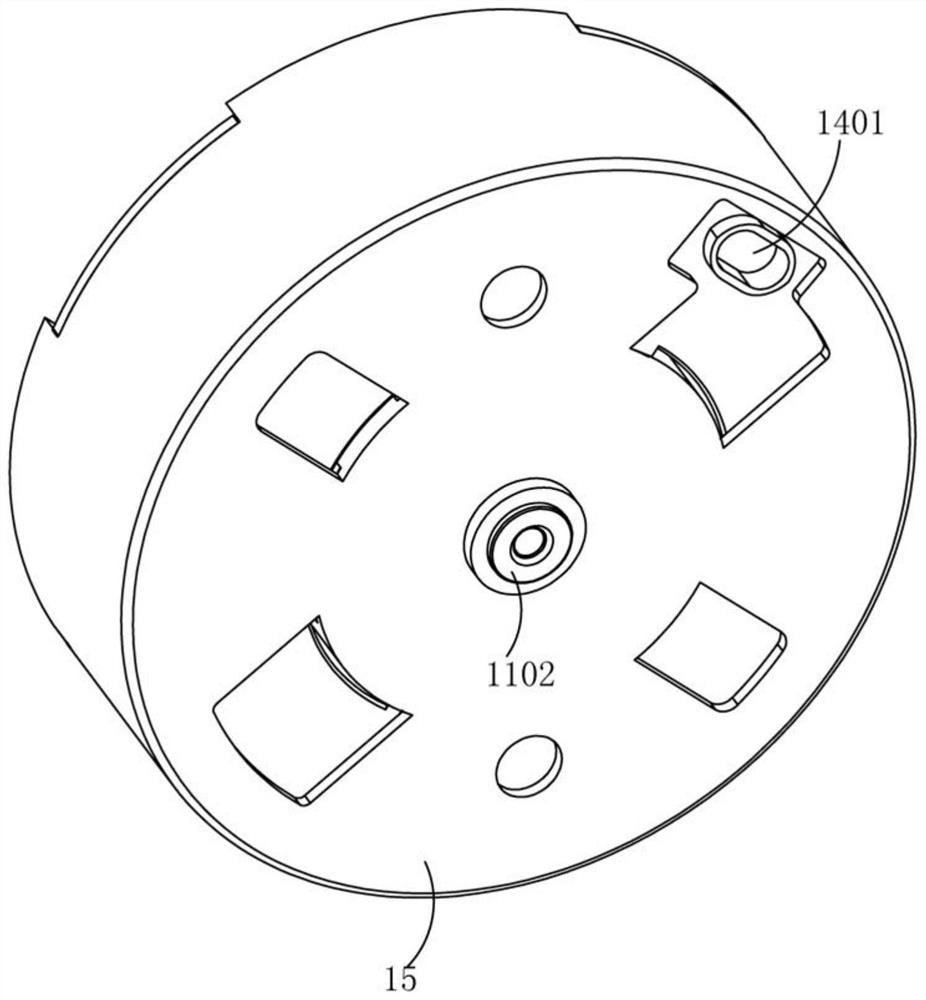

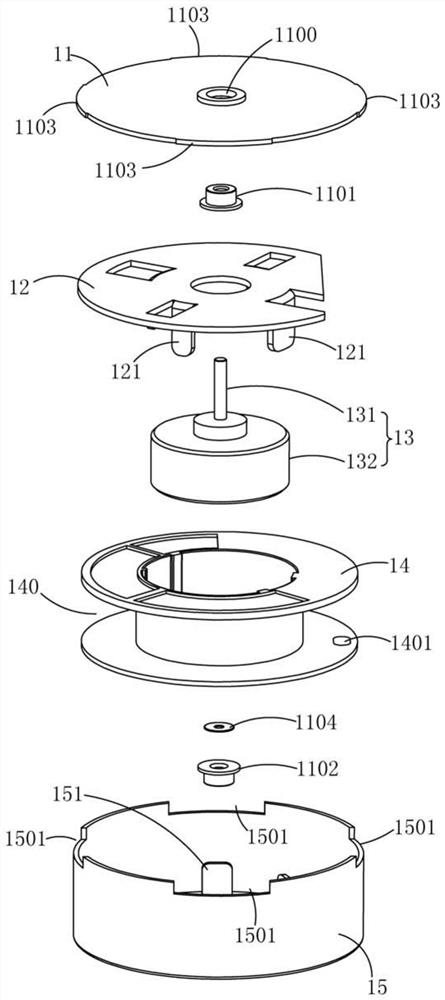

[0021] A high-precision synchronous motor, such as Figure 1 to Figure 6 As shown, it includes a casing 15, a rotor 13 disposed in the inner cavity of the casing 15, and a top cover 11 assembled on the casing 15. The rotor 13 includes an output shaft 131 having an output shaft 131 diameter d3, and the center position of the top cover 11 is set There is an upper bearing 1101 with a first inner diameter d1, the upper part of the output shaft 131 is movably inserted in the upper bearing 1101, the circumferential wall of the output shaft 131 and the inner ring wall of the upper bearing 1101 are clearance fit to form a matching width d11, satisfying the relationship 0.7≤ d11 / d1<1.15; a lower bearing 1102 with a second inner diameter d2 is provided at the center of the bottom of the casing 15, and the lower part of the output shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com