Minced fish meat food production line

A production line and surimi technology, which is applied in the field of surimi food production line and can solve problems such as greasy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

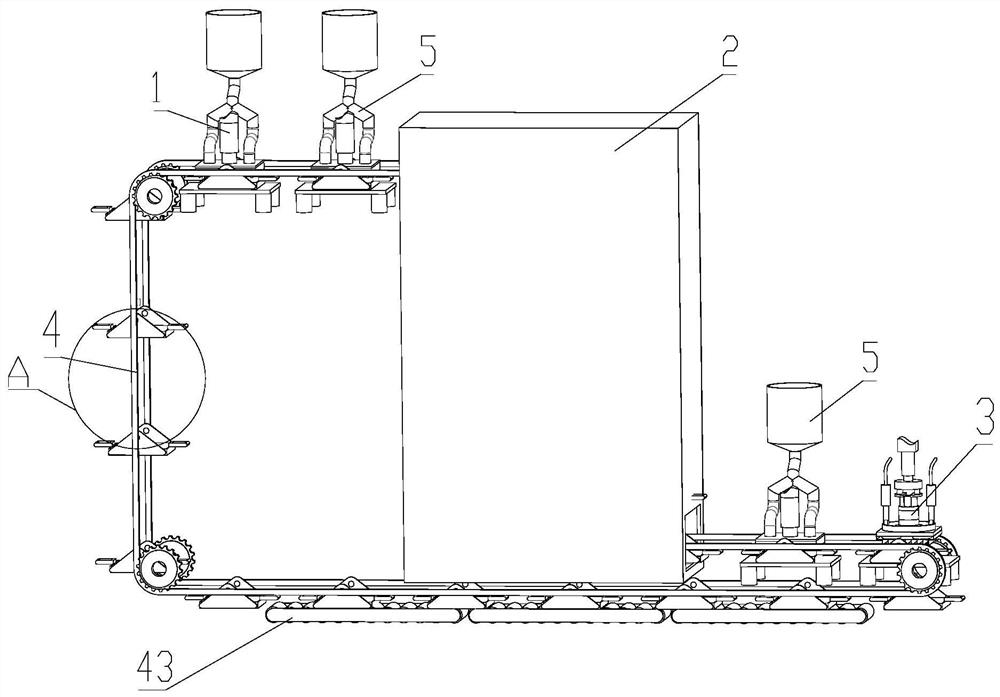

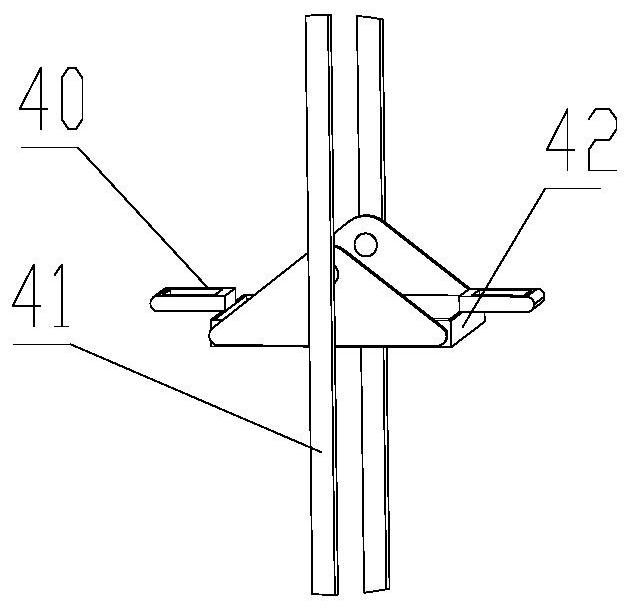

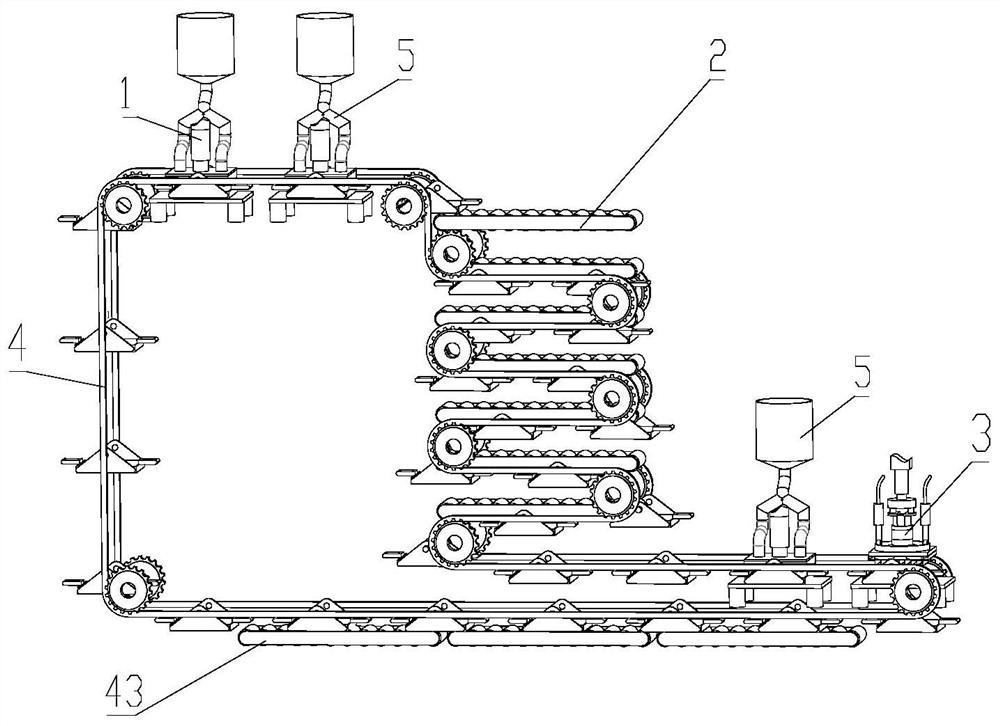

[0043] see Figure 1 to Figure 7 , the present invention provides a minced fish food production line, which includes a minced meat production unit, a filling unit 1, a shaping unit 2, a cutting unit 3, and a packaging unit arranged in sequence, and also includes a sprocket chain combination 4 as a transmission mechanism; the mold used for the filling unit It is a square shallow dish, and the shaping unit adopts the method of electric grill heating to shape the fish tofu, and the sprocket chain combination 4 passes through the box body of the shaping unit 2;

[0044] Between the filling unit 1 and the shaping unit 2, there is a covering unit 5 for adding a second material on the upper surface of the material as a covering surface.

[0045] The minced meat production unit adopts conventional technology, and usually includes a chopping device, which is used to prepare materials and seasonings into minced meat, which will be loaded into a mold in the next step.

[0046] The filling...

Embodiment 2

[0070] see Figure 5 and Image 6 , On the basis of Example 1, different from Example 1 is that a single cutting device is used to cut the shaped fish tofu.

[0071] Cutting unit 3 comprises the cutter group 301 that is positioned at the bottom, and described cutter group 301 is made up of several blades that are arranged in parallel; The upper side of cutter group 301 is horizontally provided with heating box 302, and electric heating tube is arranged in the heating box 302; 301, the heating box 302 is made of stainless steel, and the upper part of the heating box 302 is provided with a push rod mechanism that allows the cutter group 301 to press down.

[0072] The push rod mechanism includes a main push rod 303 arranged on the central upper part of the heating box 302, and auxiliary push rods 304 on both sides of the main push rod 303; the bottom end of the main push rod 303 and the upper surface of the heating box 302 A steering mechanism 305 is arranged between them, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com