Manufacturing equipment and manufacturing process of sound insulation paint facilitating printing and hanging picture pasting

A technology for sound-proof coatings and manufacturing equipment, applied in transportation and packaging, chemical instruments and methods, mixers with rotating stirring devices, etc., which can solve problems such as waste, difficulty in recycling, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

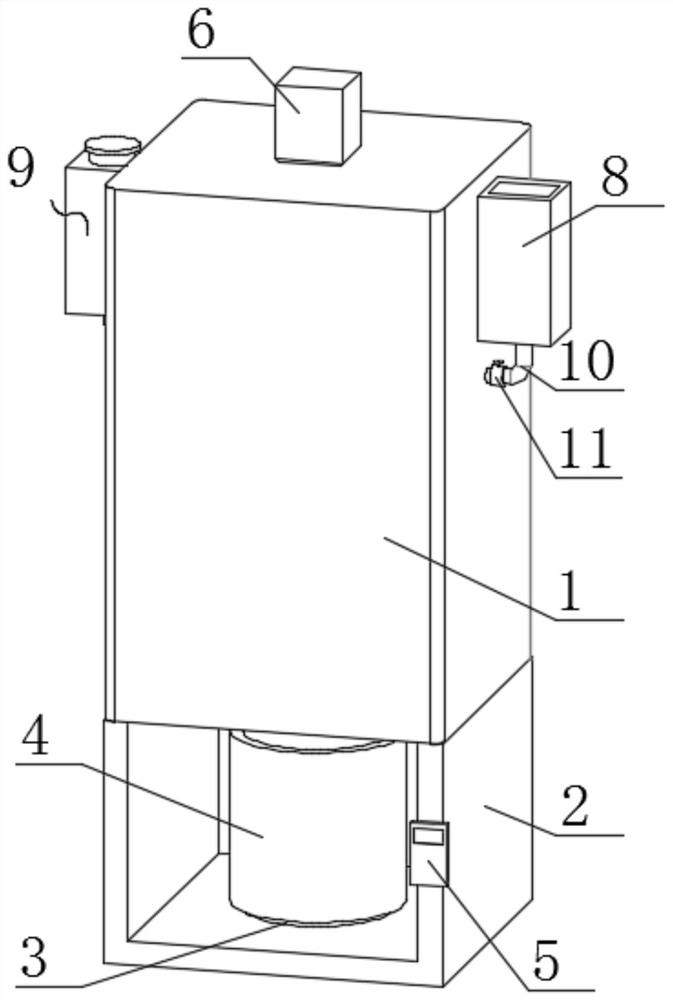

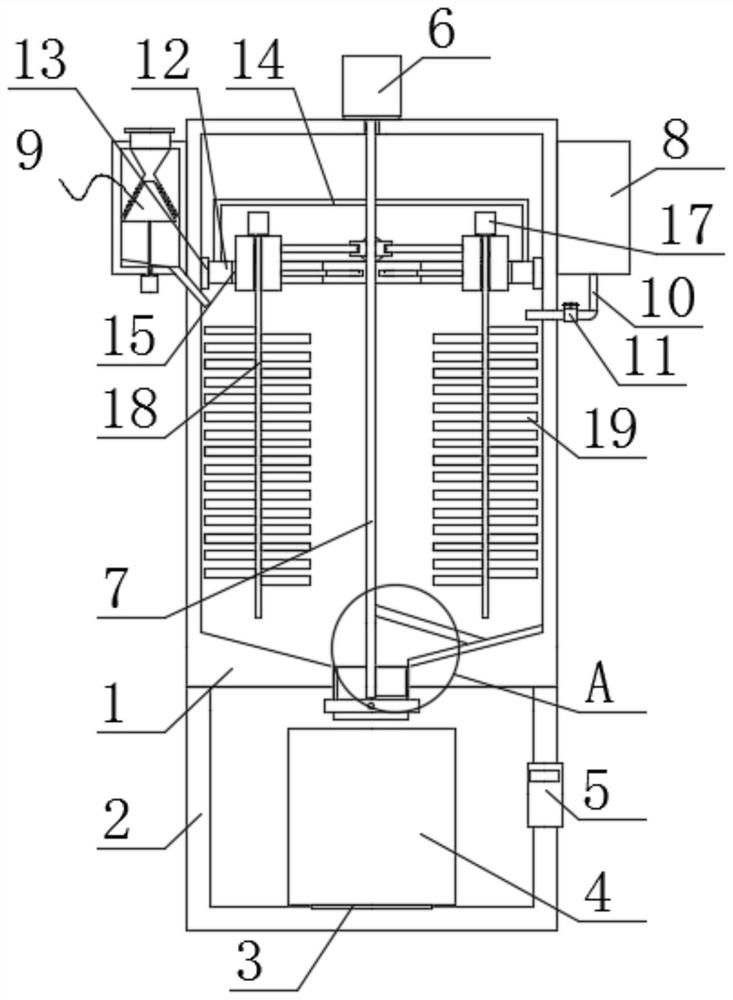

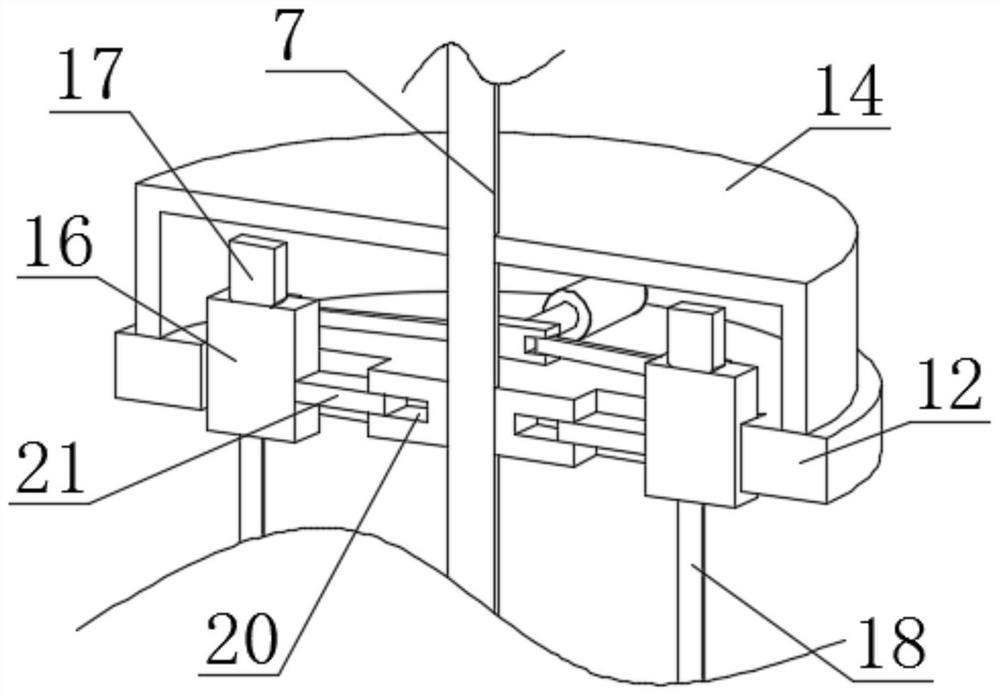

[0034] see Figure 1-7 , a manufacturing process of sound-insulating paint that is convenient for printing and pasting hanging pictures. The manufacturing equipment of the sound-proof coating for pasting hanging pictures, including a housing 1, a bucket 8 and a grinding mechanism 9, the upper surface of the housing 1 is fixedly connected with a first motor 6, and the output shaft of the first motor 6 is fixedly connected with a first rotating shaft 7 , the top of the outer surface of the first rotating shaft 7 is fixedly connected with a circular block 12, the upper surface of the circular block 12 is fixedly connected with a guard plate 14, the middle part of the outer surface of the first rotating shaft 7 is fixedly connected with a scraper 26, the first rotating shaft 7 The bottom of the outer surface is fixedly connected with a dispersing plate 27, the inside of the housing 1 is fixedly embedded with a bearing 13, the inner ring of the bearing 13 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com