Device for uniformly brushing modified starch on surface of cloth

A modified starch and brushing technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of low efficiency, time-consuming, labor-intensive cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

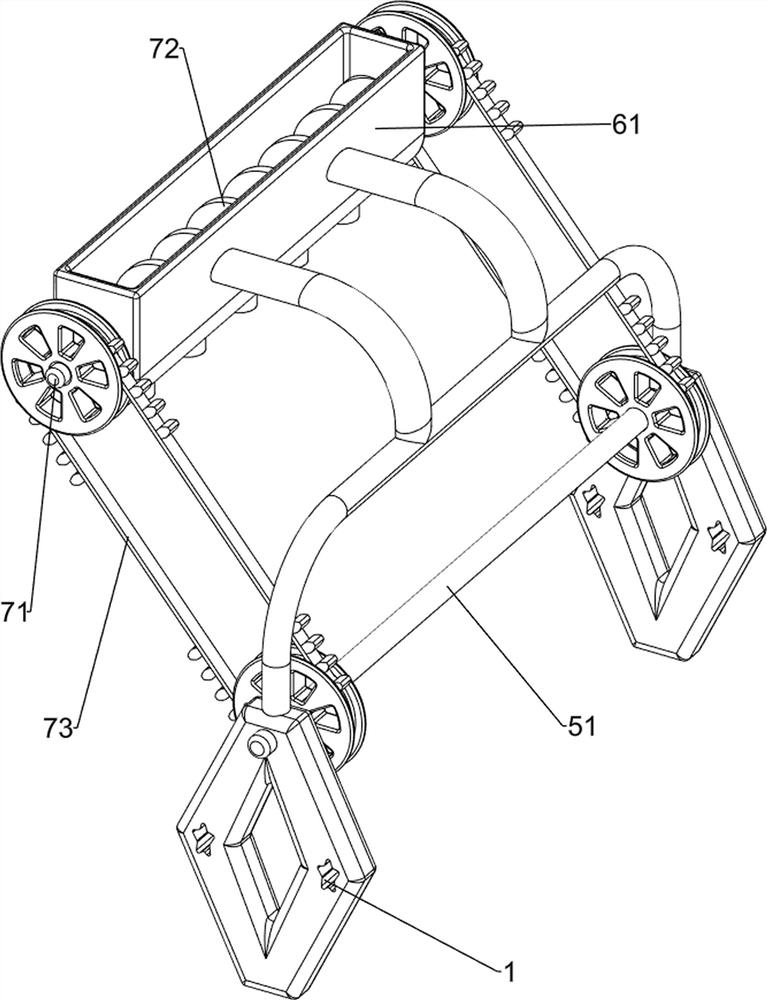

[0073] A device for evenly brushing modified starch on the surface of cloth, such as figure 1 As shown, it includes a first support frame 1, a connecting block 2, a motor 3, a first rotating mechanism 4 and a transmission mechanism 5. The first support frame 1 is provided with a connecting block 2 at the inner rear part of the left and right sides, and the left and right sides A motor 3 is installed on the top of the connecting block 2, and a first rotating mechanism 4 is provided at the rear of the inner side of the first support frame 1, and the first rotating mechanism 4 is connected with the output shaft of the motor 3, and a transmission mechanism is arranged inside the first supporting frame 1 5. The transmission mechanism 5 is connected with the first rotation mechanism 4 .

[0074] When people need to brush modified starch on the cloth, first people put the cloth in the transmission mechanism 5, and make one end wind it in the first rotating mechanism 4, then start the...

Embodiment 2

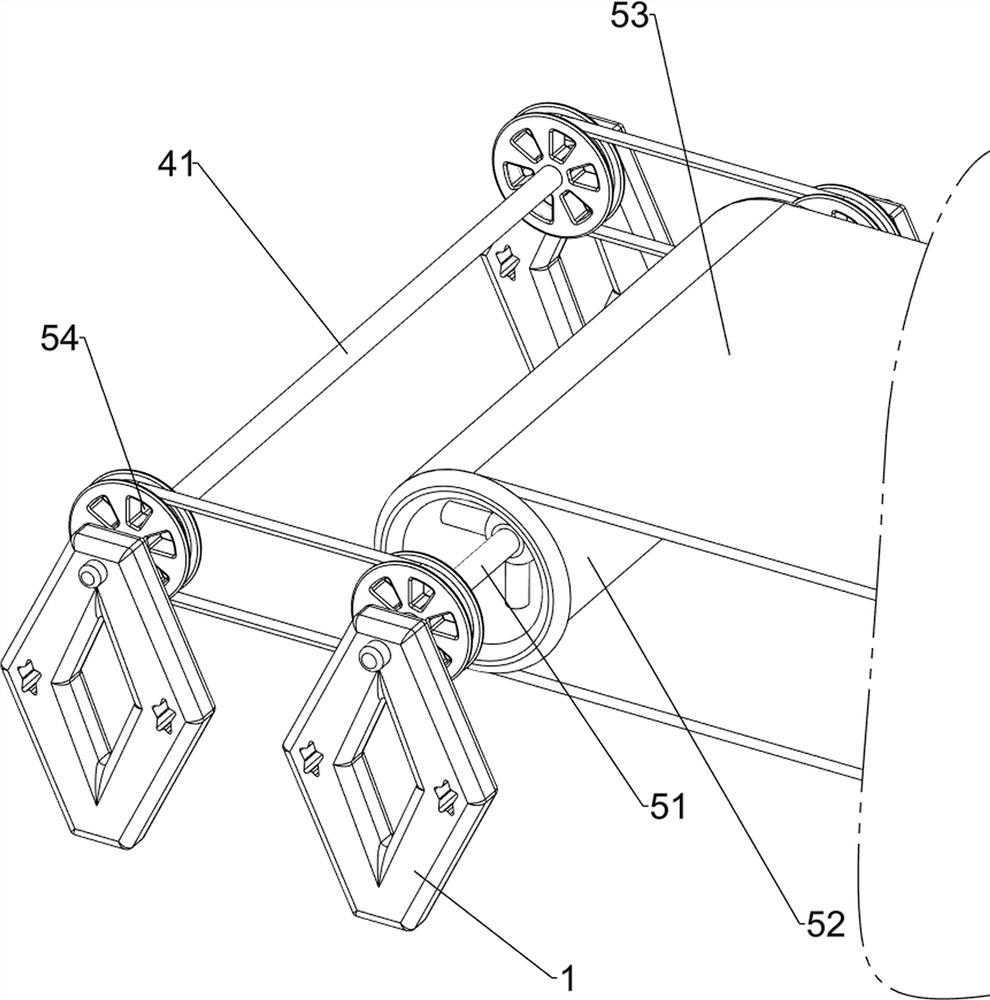

[0076] On the basis of Example 1, such as figure 2 with image 3 As shown, the first rotating mechanism 4 includes a first rotating shaft 41, a drum 42 and a first transmission assembly 43, and the first rotating shaft 41 is rotationally connected between the upper parts of the left and right sides of the inner rear part of the first support frame 1, and the first rotating shaft 41 is provided with a roller 42 , and a first transmission assembly 43 is connected between the left and right sides of the first rotating shaft 41 and the output shaft of the motor 3 .

[0077] People wind one end of the cloth around the drum 42, then start the motor 3, the output shaft of the motor 3 rotates to drive the first transmission assembly 43 to rotate, and then the first rotating shaft 41 rotates, thereby rotating the drum 42, and the drum 42 rotates and the coated The cloth with modified starch is rolled up to complete the collection of cloth. After the surface of the cloth is completely...

Embodiment 3

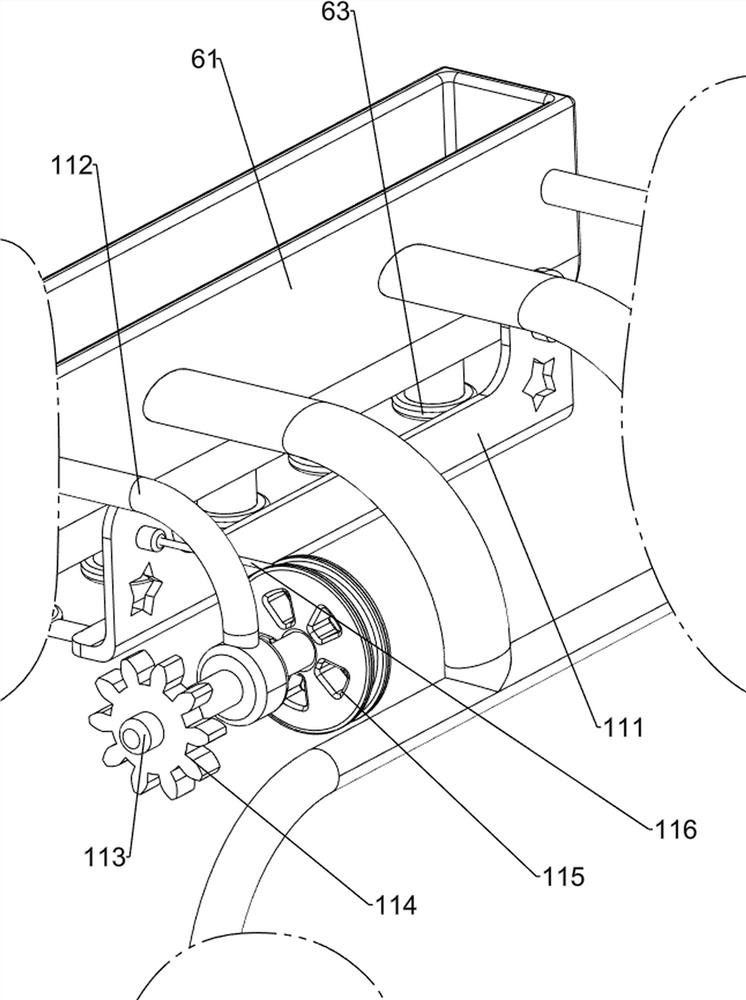

[0081] On the basis of Example 2, such as figure 1 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, a blanking mechanism 6 is also included, and the blanking mechanism 6 includes a blanking frame 61, a second support frame 62, a baffle plate 63 and a first spring 64, and the top front side of the first support frame 1 is provided with a blanking frame 61, the lower part of the rear side of the blanking frame 61 is provided with five second support frames 62, and the inner sides of the bottom of the five second support frames 62 are all slidingly provided with baffle plates 63, and the baffle plates 63 cooperate with the blanking frame 61, and the five block plates A first spring 64 is wound around each plate 63 , the front side of the first spring 64 is connected to the second supporting frame 62 , and the rear side of the first spring 64 is connected to the baffle plate 63 .

[0082] In the initial state, the baffle plate 63 cooperates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com