Automatic measurable plate shearing machine for flange production

A measurement type, shearing machine technology, applied in the direction of shearing equipment, shearing devices, shearing machine accessories, etc., can solve the problems of material waste, large plate size, inaccurate size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

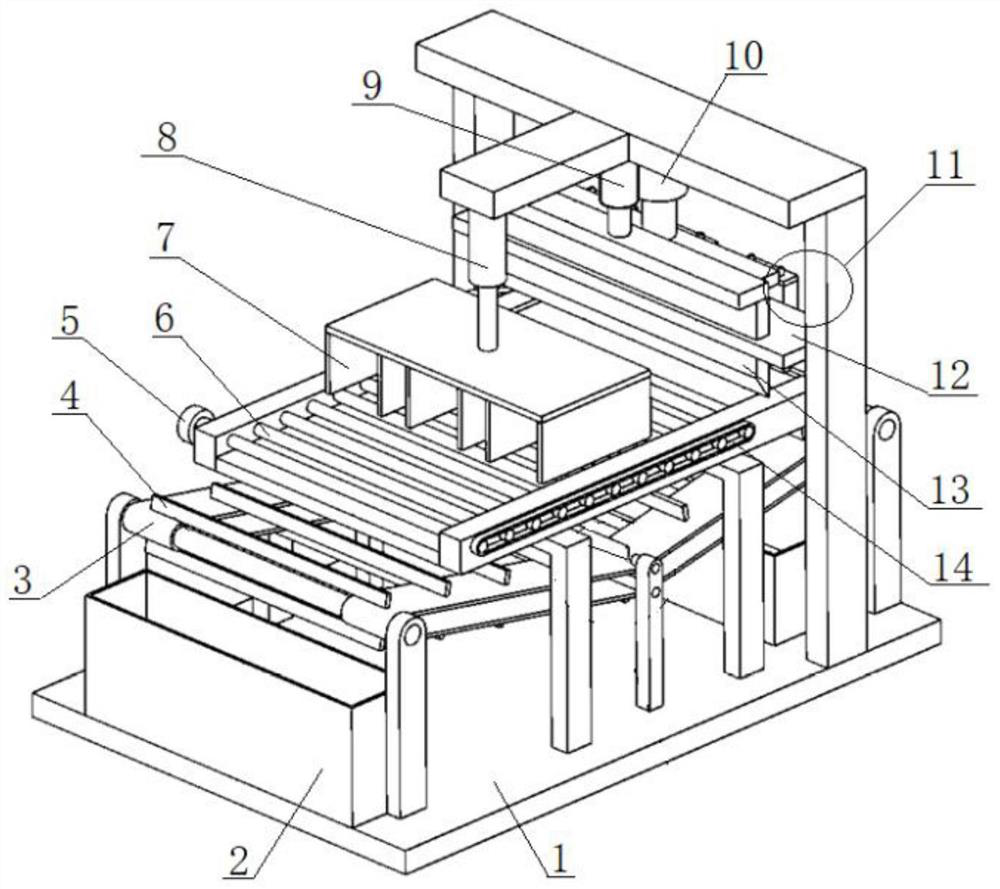

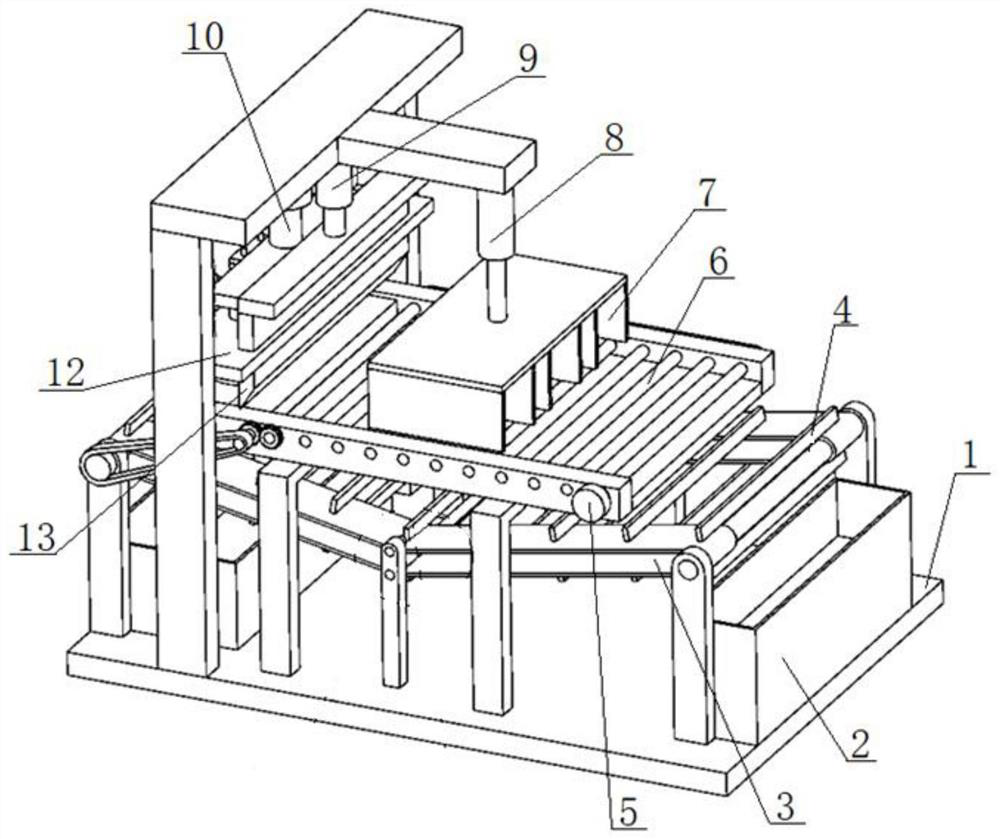

[0030] see figure 1 and figure 2 , an automatic measurable plate shearing machine for flange production, including a feeding mechanism, a cutting mechanism for cutting plates, a limit assembly 11 for determining the size of a sheared piece, a reciprocating transmission mechanism, and a limit assembly 11 It is arranged close to the cutting mechanism, the reciprocating transmission mechanism is arranged under the feeding mechanism, and the feeding mechanism, the cutting mechanism and the limit assembly 11 are arranged on the bracket.

[0031] Wherein, the bottom end of the bracket is the bottom plate 1 .

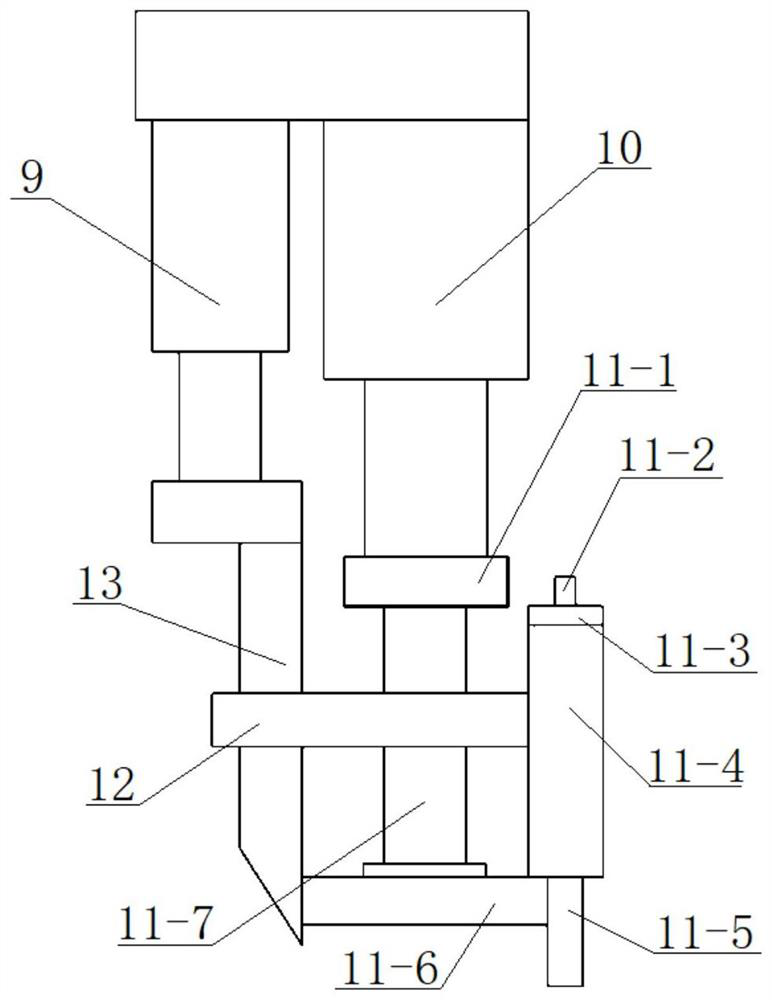

[0032] see image 3 and Figure 4 , the limit assembly 11 includes a horizontally placed flange 11-6, a vertically placed connecting shaft 11-7 connected to the flange 11-6, a cylinder three 10 vertically connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com