Elevator decoration part cutting device

A cutting device and decoration technology, which is applied in the direction of positioning device, feeding device, maintenance and safety accessories, etc., can solve the problems that the decoration board 14 cannot be cut flexibly, and the flexibility is not enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

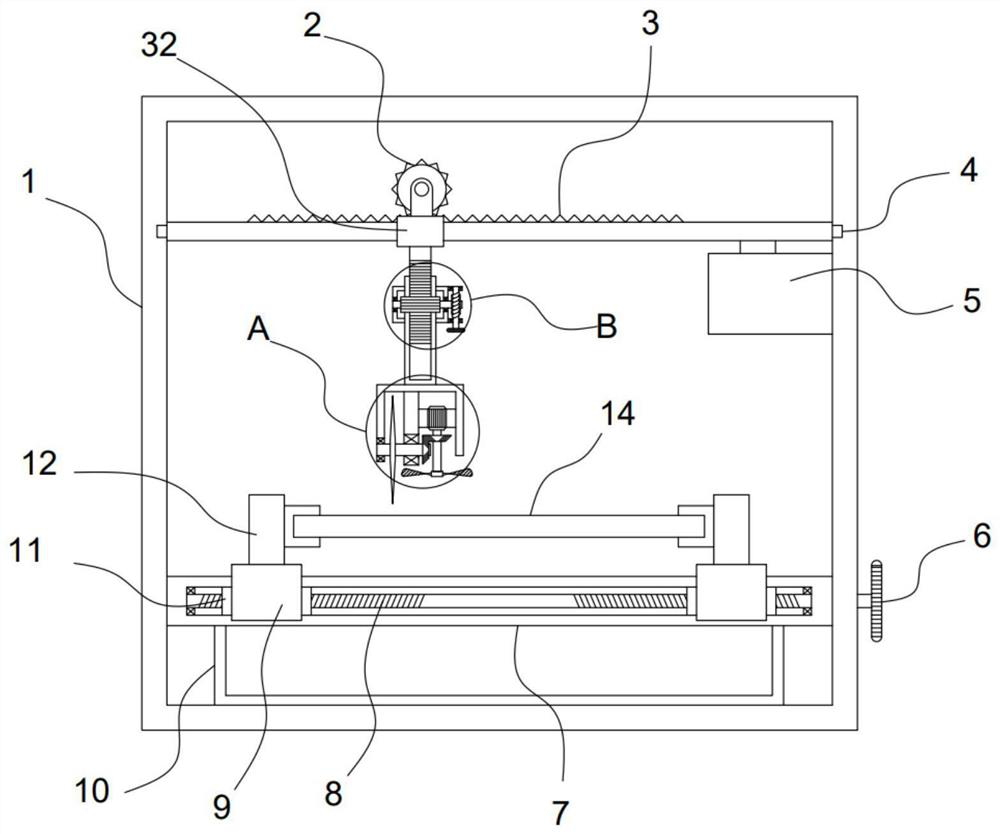

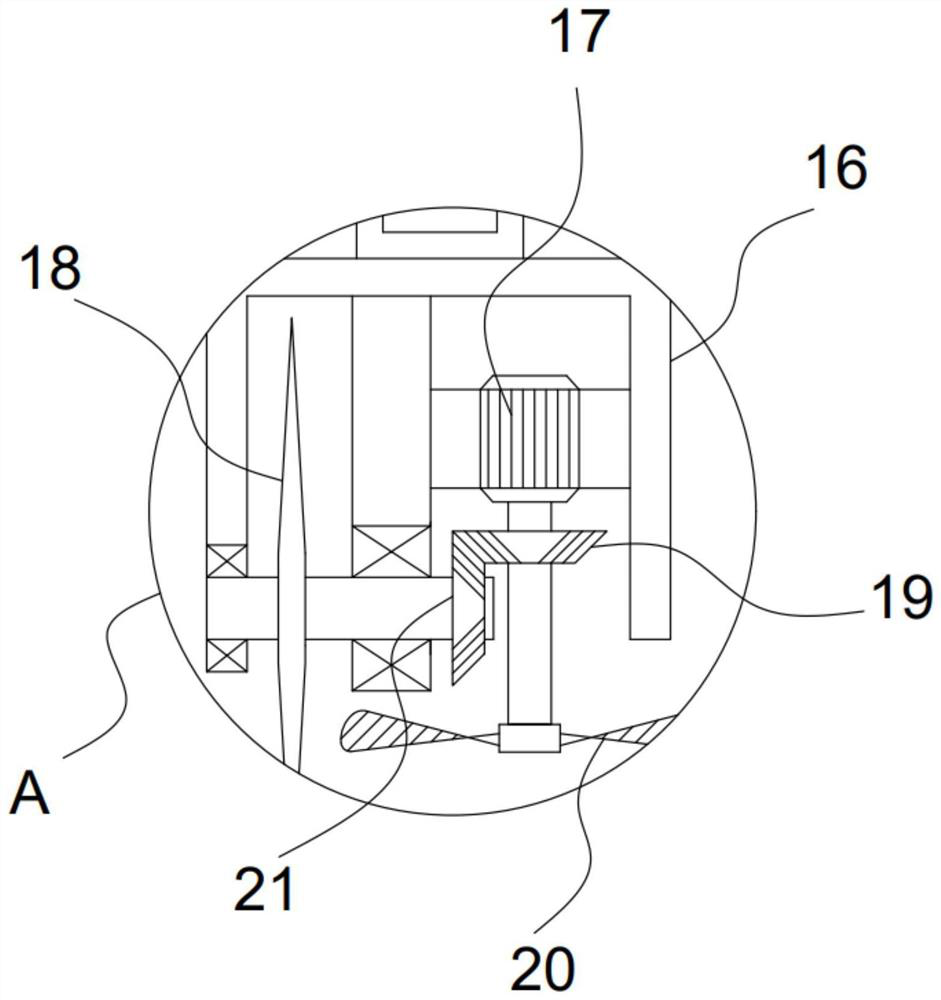

[0024] see Figure 1-5 , a cutting device for elevator decoration parts, comprising a fixed frame 1, a support frame 7 is fixed on the fixed frame 1, a collection tank 10 is fixed on the bottom of the support frame 7, a hand wheel 6 is installed on the fixed frame 1, and a hand wheel 6 The upper drive is connected with a clamping mechanism installed on the supporting frame 7, and a pair of clamping seats 12 are connected to the clamping mechanism to fit the decorative board 14. The transmission box 5 is fixed on the fixed frame 1, and the transmission box 5. The upper drive is connected with a translation mechanism, which is driven and connected with a horizontal rack 3. An adjustment mechanism is slidably installed on the horizontal rack 3. A vertical rack 23 is vertically fixed at the bottom of the adjustment mechanism. The sliding sleeve on the bar 23 is provided with a lifting mechanism, and a cutting mechanism for cutting the decorative board 14 is installed at the bottom...

Embodiment 2

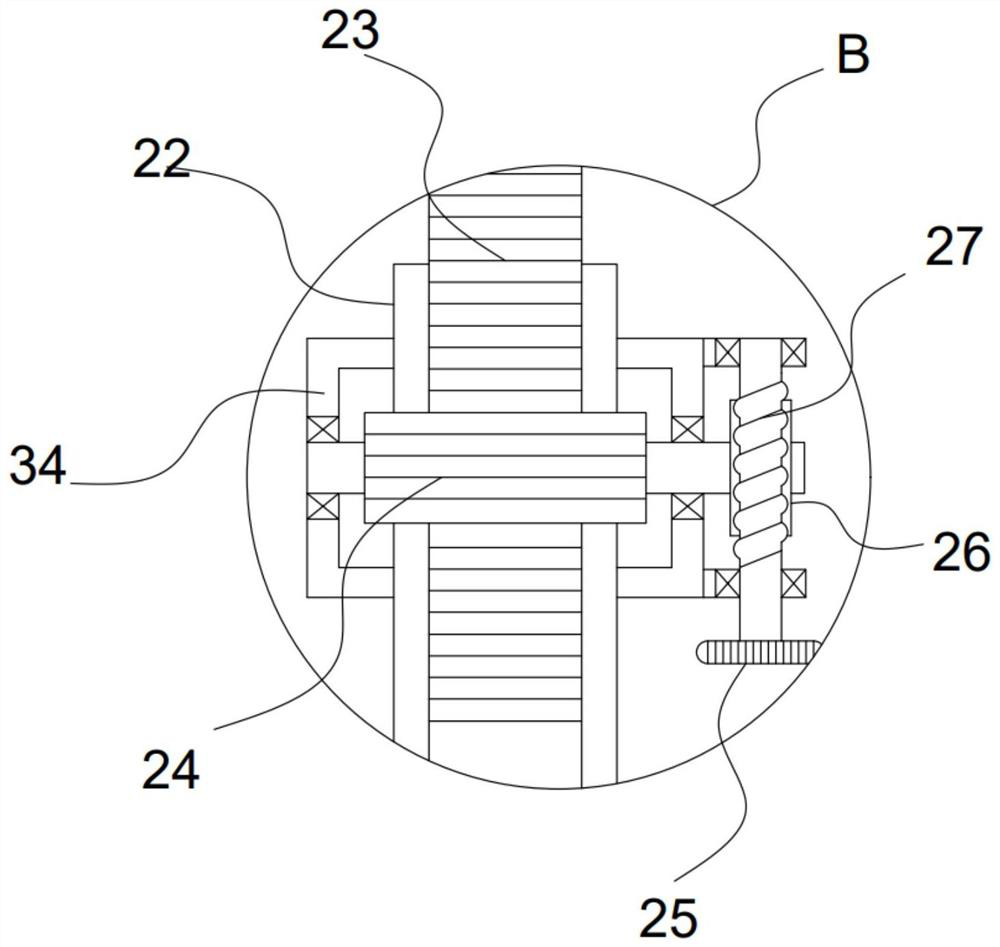

[0030] On the basis of Embodiment 1, in addition, this device is also provided with a translation mechanism, including a servo motor 31 fixed in the transmission box 5, and an incomplete bevel gear 30 is driven and connected to the servo motor 31, and the transverse rack 3. The bottom is fixed with a threaded cover block 29. The threaded cover block 29 is threaded with a reciprocating screw 28. The reciprocating screw 28 is sleeved with a bevel gear I13 and a bevel gear II15 that alternately mesh with the incomplete bevel gear 30.

[0031] The set servo motor 31 drives the incomplete bevel gear 30 to rotate, and the incomplete bevel gear 30 is meshed with the bevel gear I13 and the bevel gear II15 alternately. At this time, the reciprocating screw 28 rotates alternately clockwise and counterclockwise. At this time, the reciprocating screw 28 drives the threaded block 29 drives the transverse rack 3 to perform reciprocating motion, that is, the cutting mechanism realizes recipro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com