Manufacturing and processing technology of antibacterial plastic airplane meal box

A processing technology and antibacterial plastic technology, which is applied in the field of antibacterial plastic aircraft lunch box production and processing technology, can solve the problems of uneven distribution of antibacterial agents, poor uniformity, and affecting the antibacterial effect of lunch boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

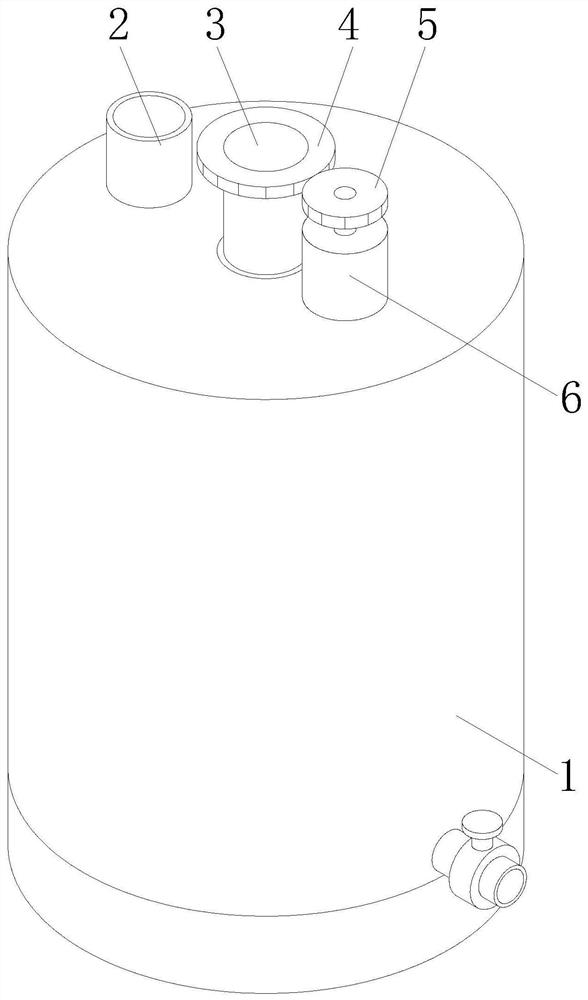

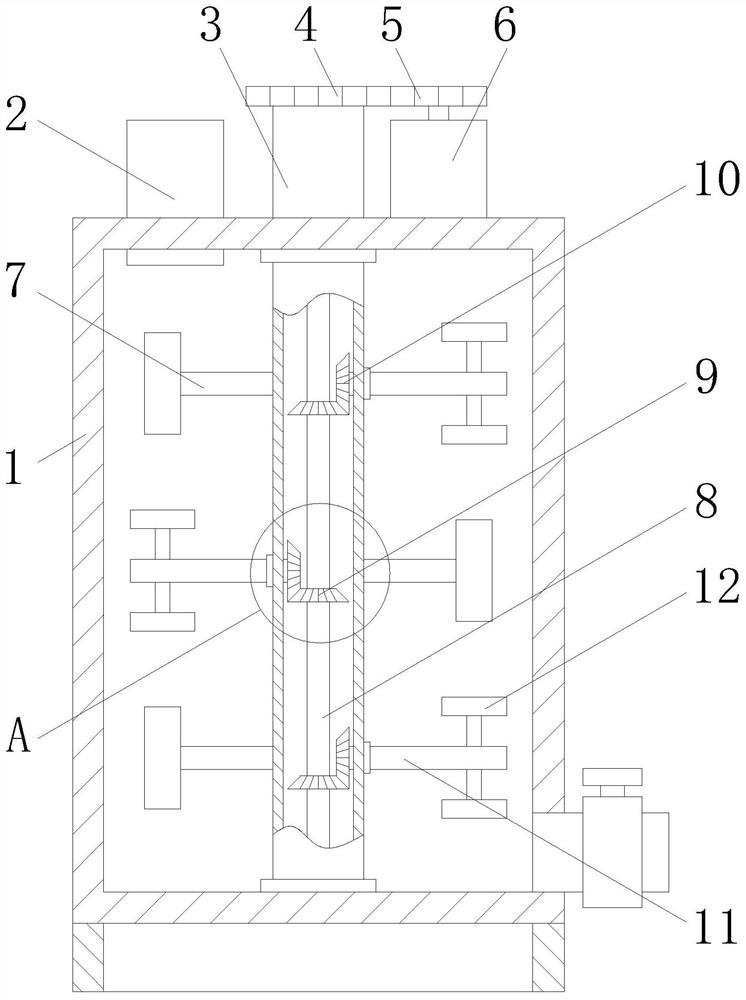

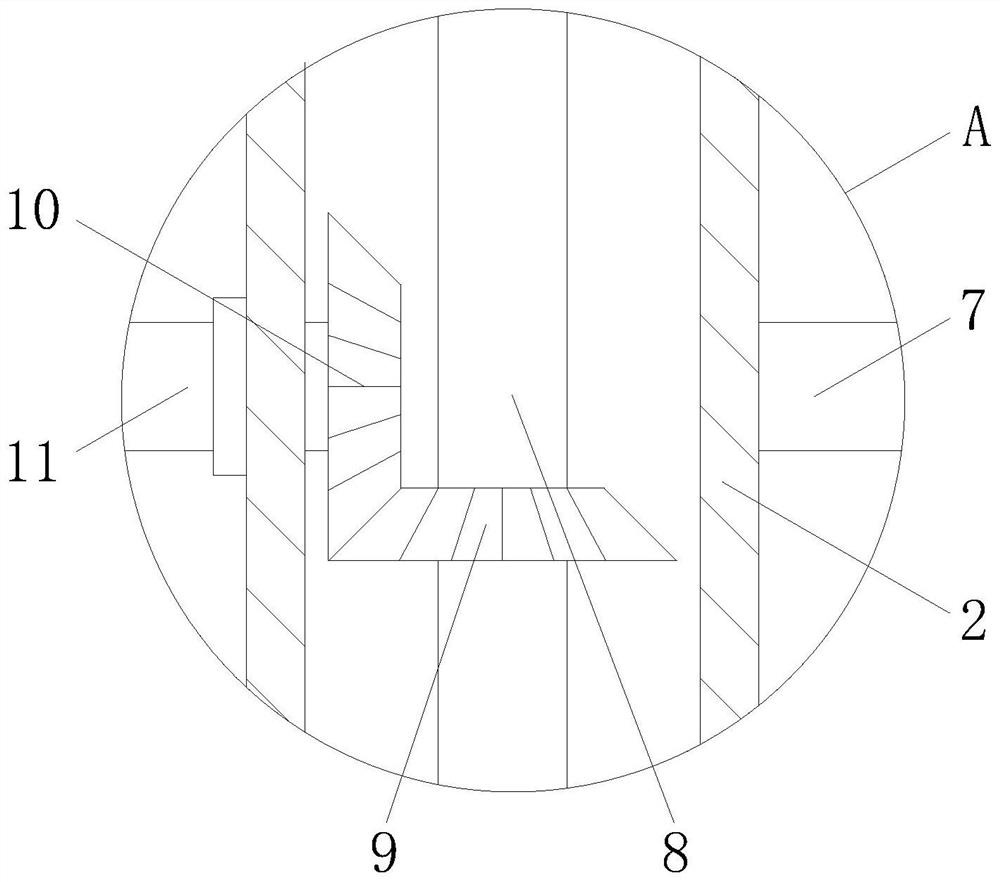

[0041] Example: such as Figure 1-11 Shown, a kind of antibacterial plastics aircraft meal box of the present invention manufactures and processes, comprises the following steps:

[0042] A. Mixing treatment of raw materials, adding antibacterial agent to the raw material of plastic granules, and then using a stirring device to stir, so that the antibacterial agent and plastic granules are evenly mixed;

[0043] The stirring device includes a stirring tank 1, and a stirring mechanism is arranged inside the stirring tank 1. The stirring mechanism consists of a feeding pipe 2, a supporting pipe 3, a driven wheel 4, a driving wheel 5, a stirring motor 6, and several first stirring blades. 7. A support rod 8, several first bevel gears 9, several second bevel gears 10, several rotating shafts 11 and several second stirring blades 12.

[0044] B, the processing of the lunch box, the raw materials mixed in step A are added to the processing equipment, and processed by the processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com