Loading disc grabbing device

A carrier plate and cylinder hole technology, applied in the direction of coating, etc., can solve the problems of difficult positioning of the mold and the increase of cumulative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

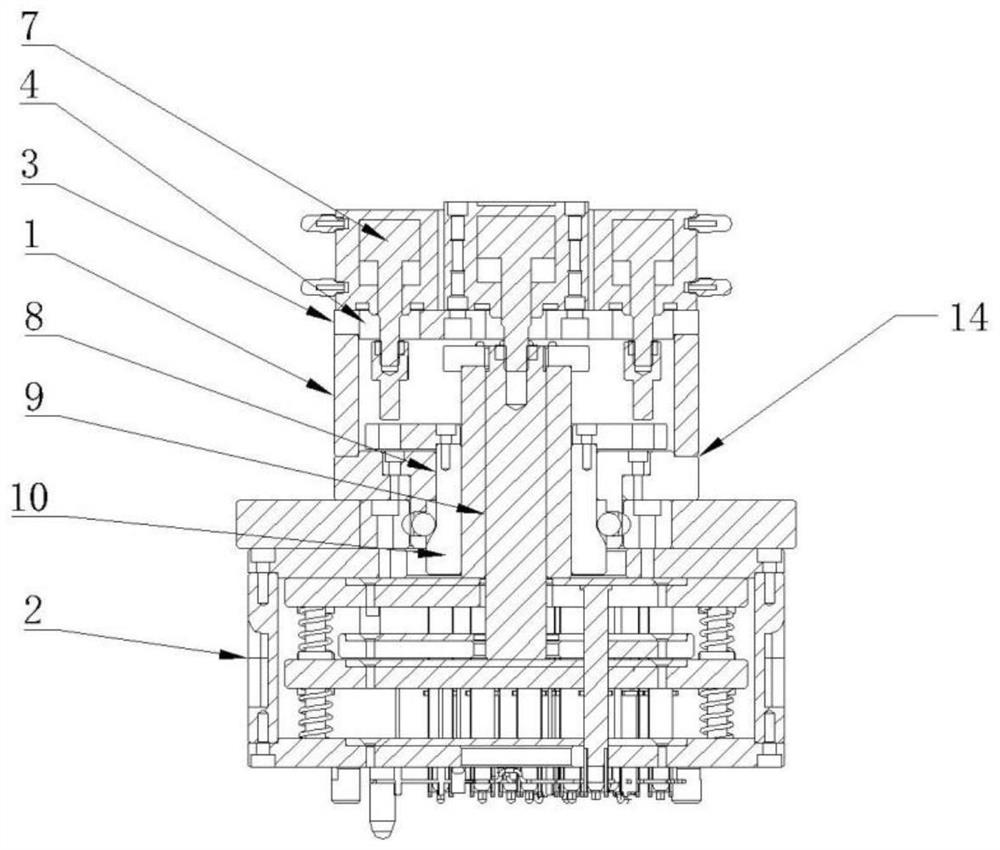

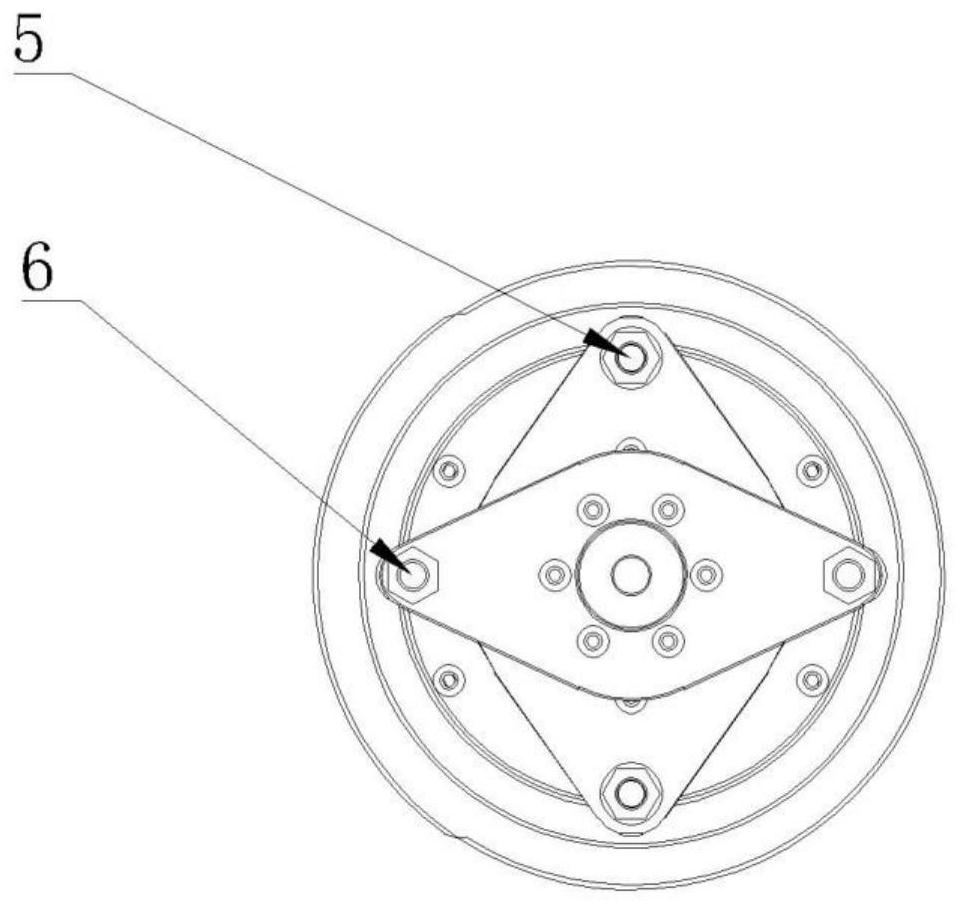

[0033] Such as Figure 1-3 , the present embodiment has two positioning column cylinder holes 5, arranged according to the mirror image of the center point of the cylinder fixed plate 3; The cylinder 7 links the column body 8 through the linkage device 27 . Linkage device 27 comprises cylinder piston rod extension rod 28 and connecting plate 29, and cylinder 7 connects cylinder piston rod extension rod 28, and cylinder piston rod extension rod 28 is fixed on the connecting plate 29, and connecting plate 29 is fastened on the cylinder 8. The cylinder piston rod extension rod 28 is screwed and fixedly connected with the connecting plate 29 . The connecting plate 29 and the column body 8 are fastened by screws and threads. The connecting plate 29 is a diamond-shaped plate, and a through hole for the column body 8 to pass through is provided in the middle of the diamond-shaped plate.

[0034] When in use: let the cylinder 7 push the connecting plate 29, the connecting plate 29 ...

Embodiment 2

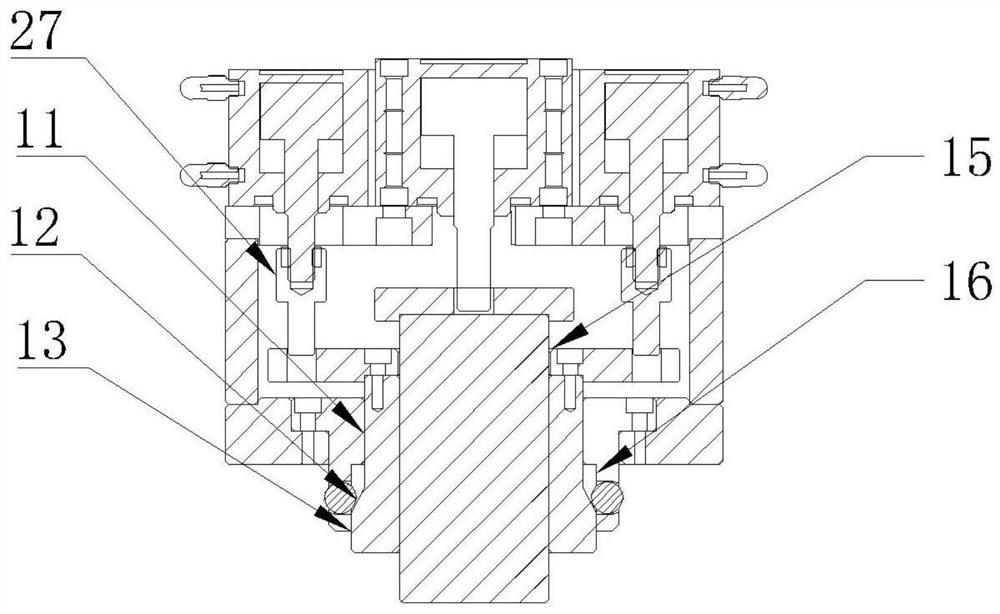

[0037] Such as Figure 4-5 , this embodiment is based on the first embodiment, the cylinder hole 4 also includes a central column cylinder hole 24 arranged in the center of the plane of the cylinder fixing plate 3, the central column cylinder hole 24 corresponds to the cylinder linkage central column 25, and the central column 25 runs through The center of the positioning column 9 is slidably matched with the positioning column 9; the center bottom of the positioning counterbore 23 is provided with a central counterbore 26 which is slidably matched with the central column 25.

[0038] When in use: let the cylinder 7 push the connecting plate 29 and the central column 25, the connecting plate 29 links the cylinder 8, compress the cylinder 8, the central column 25 and the carrier body 2, and compress the central column 25 and the central counterbore 25, Tighten the push column cylinder, push the column cylinder back to push the push column 10, the inclined surface 12 of the push...

Embodiment 3

[0041] Such as Figure 6 , this embodiment is based on Embodiment 1 or 2, the positioning assembly 19 includes a positioning plate 30 and an assembly plate 31, the positioning plate 30 is placed at the center of the assembly plate 31, and the positioning through hole 21 is placed at the center of the positioning plate 30.

[0042] When in use: let the cylinder 7 push the connecting plate 29 and the central column 25, the connecting plate 29 links the cylinder 8, compress the cylinder 8 and the positioning through hole 21 of the positioning plate 30, and compress the central column 25 and the central counterbore 25, Tighten the push column cylinder, push the column cylinder back to push the push column 10, the inclined surface 12 of the push column 10 pushes the stuck ball 18 into the sink hole on the ball surface, the stuck ball 18 extends out of the spherical sink hole 17, clamps the spherical groove 22, and tightens the positioning The cylinder of the column and the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com