Special film blowing device for multi-layer co-extrusion of environment-friendly rich mineral paper

A technology of environmental protection stone paper and multi-layer co-extrusion, which is applied in the field of blown film manufacturing process equipment of stone paper and special blown film device for environmental protection stone paper multi-layer co-extrusion, which can solve the problems of narrow application range and single product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

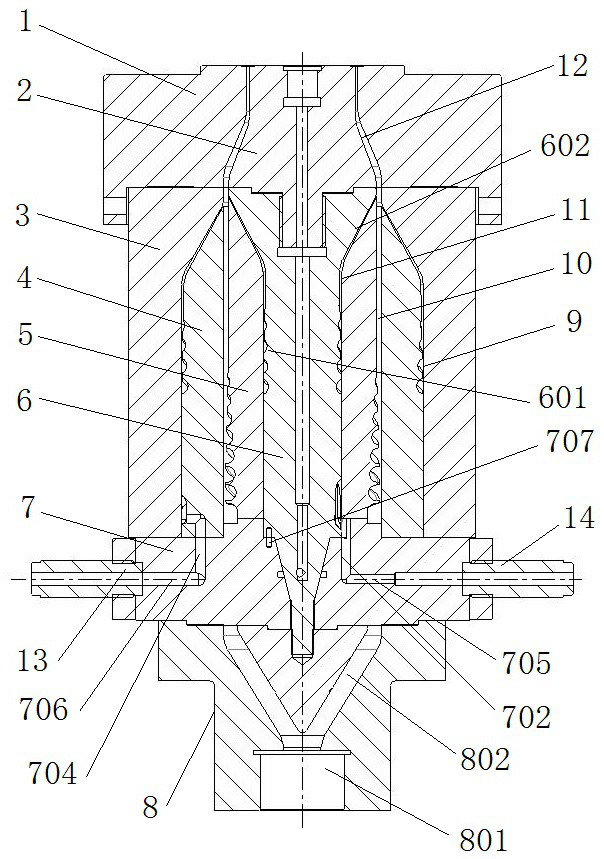

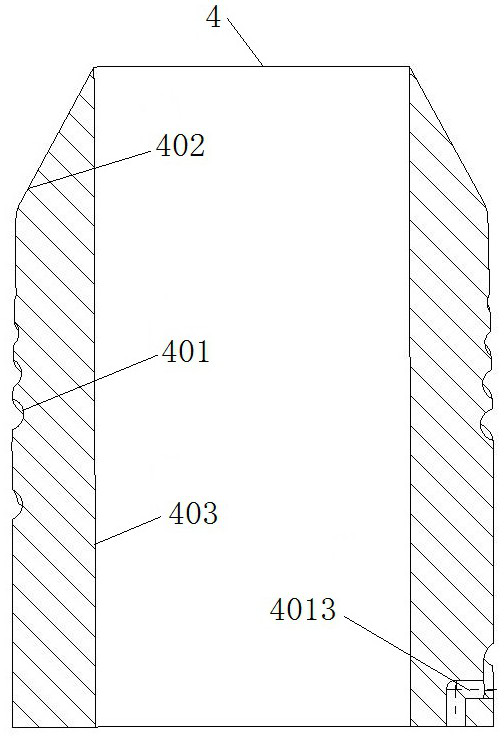

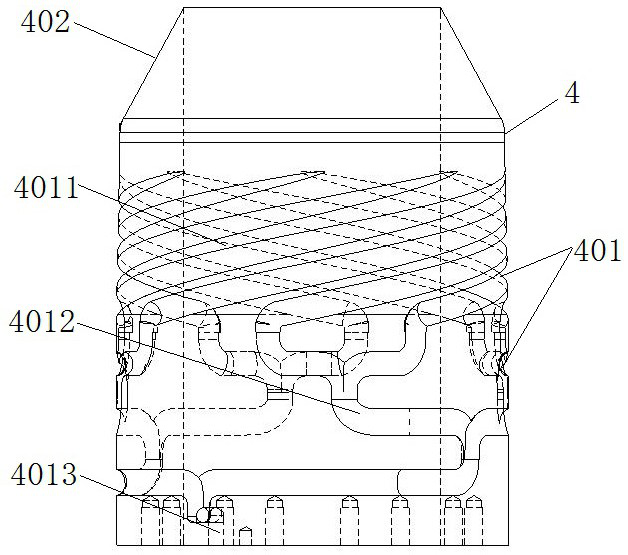

[0032] Example: such as Figure 1-8As shown, a special film blowing device for environmental protection stone paper multi-layer co-extrusion according to the present invention is composed of a main extruder, an outer sub-extruder, an inner sub-extruder connected to a rotating die and a control system. The rotary die head is composed of an outer die mouth 1, an inner die mouth 2, an outer die body 3, an outer core 4, a middle core 5, an inner core 6, a splitter plate 7 and a splitter cone 8.

[0033] The outer core 4, the middle core 5 and the inner core 6 are sequentially connected to the inside of the outer mold body 3 from the outside to the inside, and the outer walls of the three cores are connected in the outer mold body 3 to form the outer layer flow channel 9, the middle layer flow channel 10 and the inner layer flow channel respectively. The layer flow channel 11, the outer layer flow channel 9 and the inner layer flow channel 11 are converging and communicating with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com