Anti-rebound horizontal household garbage dehydrator

A domestic waste, anti-rebound technology, applied in the direction of presses, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of occupied volume, garbage clogging, low compression rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

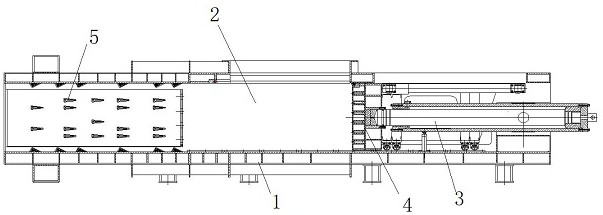

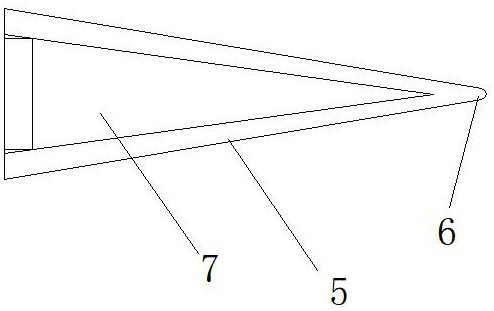

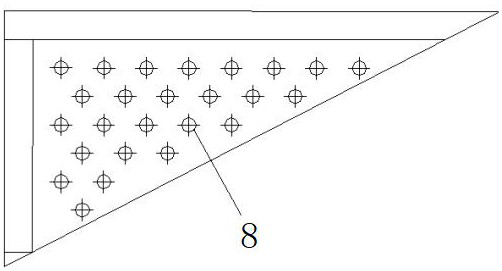

[0026] see Figure 1 to Figure 5 , the present invention relates to an anti-rebound horizontal household garbage dehydrator, comprising a frame 1, a cavity 2 is arranged inside the frame 1, a main pressure oil cylinder 3 is arranged on one side of the cavity 2 of the frame 1, and the main pressure oil cylinder 3 is equipped with pusher head 4, after the main pressure cylinder 3 pushes the pusher head 4, the garbage in the cavity 2 is pushed backward, and the inner wall of the rear side of the cavity 2 is provided with an anti-rebound block 5. The rebounding block 5 is an isosceles triangle, and the top of the anti-rebounding block 5 is a sharp angle 6, and the design of the sharp angle 6 can pierce the garbage bag, thereby reducing the volume occupied by the garbage bag and further improving the garbage compression effect.

[0027] The anti-rebound block 5 can play the effect of squeezing the rubbish pushed inward, thereby further squeezing out the sewage in the rubbish and im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com