Intelligent control device and method for preventing conveyor belt from deviating

An intelligent control and conveyor belt technology, applied in conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of conveyor belt edge cracking, excessive deviation correction, affecting the normal service life of conveyor belts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

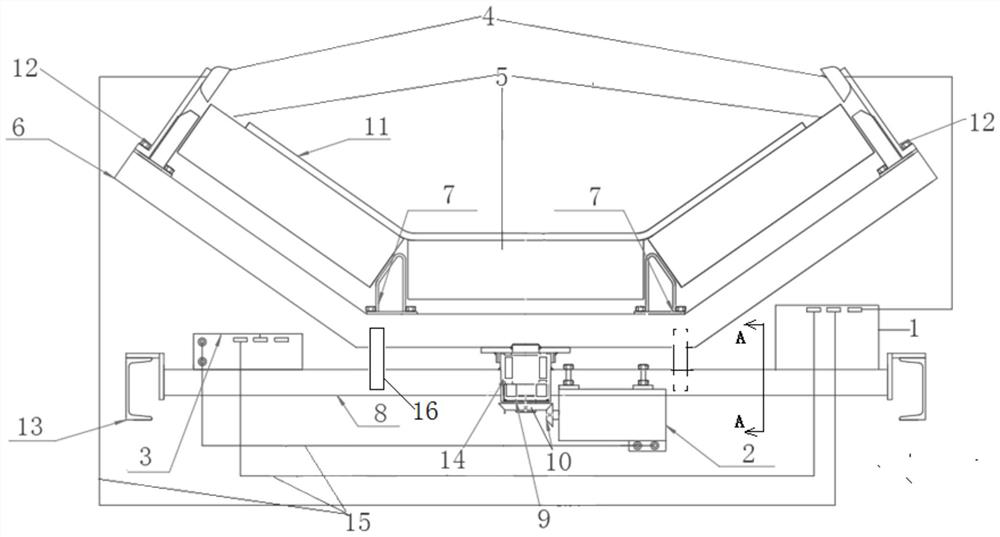

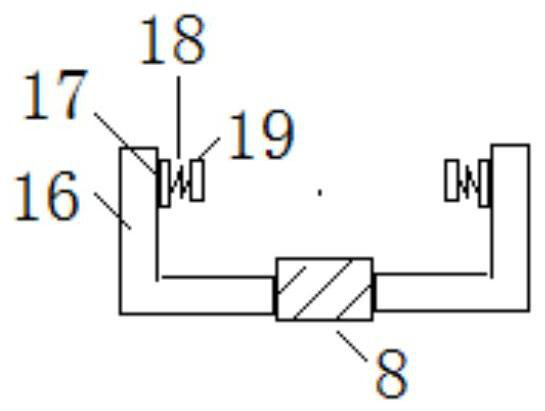

[0019] An intelligent control device for preventing deviation of the conveyor belt according to the present invention includes PLC, servo motor, driver, two ultrasonic distance measuring sensors, three rollers, swing bracket, roller support seat, lower joist, and rotating shaft , gear set, and two safety limit devices; the lower joist is fixed on the conveyor frame, the bearing group is connected to the lower joist, the swing bracket is welded to the rotating shaft and inserted into the bearing group for fastening, and the end of the rotating shaft is fitted with gears And fixed, the servo motor is horizontally placed under the lower joist, the servo motor shaft head is equipped with a gear, the end gear of the rotating shaft meshes with the gear of the servo motor shaft head, the driver is placed on the lower joist, and the PLC is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com