Steel pipe galvanizing and processing equipment

A technology for processing equipment and steel pipes, which is applied in hot-dip plating process, metal material coating process, cleaning hollow objects, etc., and can solve the problems of high labor cost, hidden safety hazards of workers, and difficulty in mixing evenly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

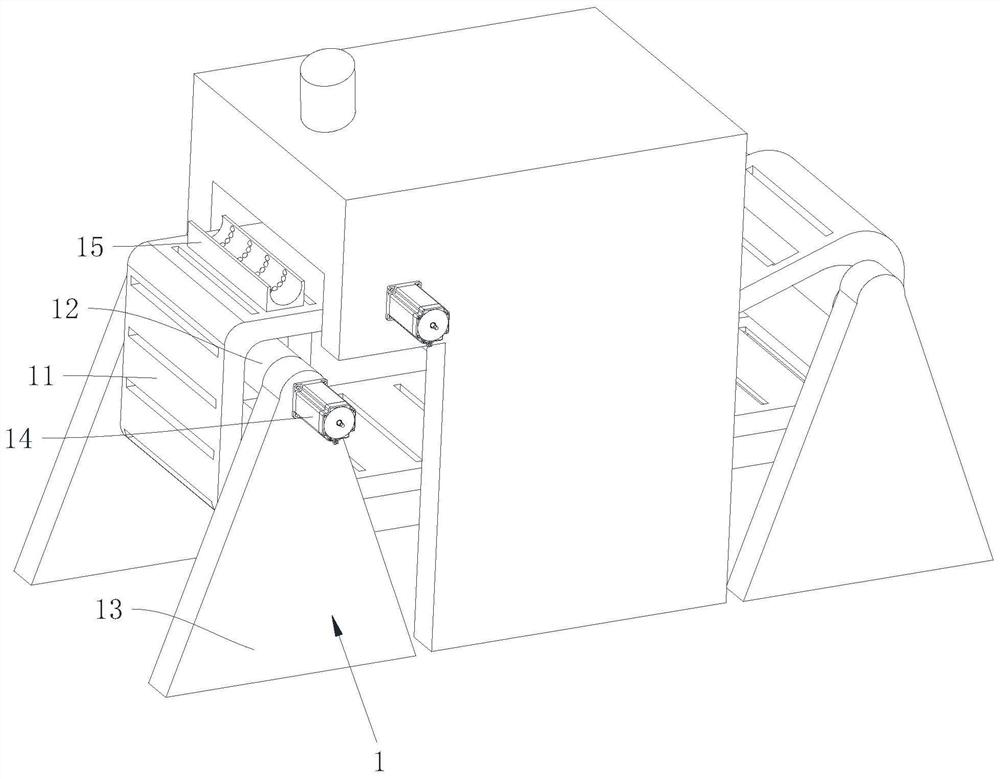

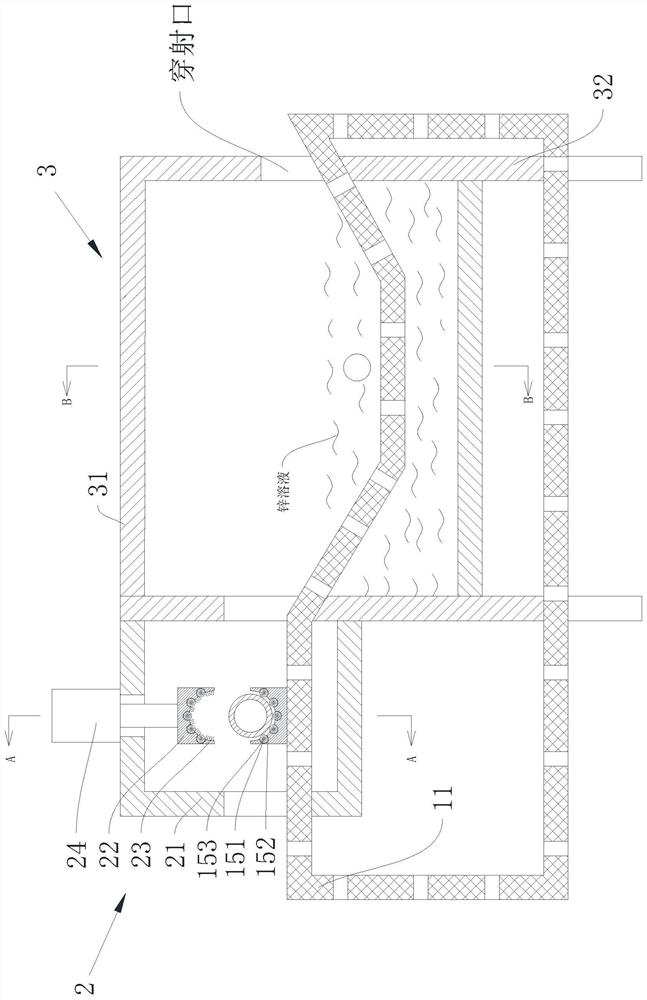

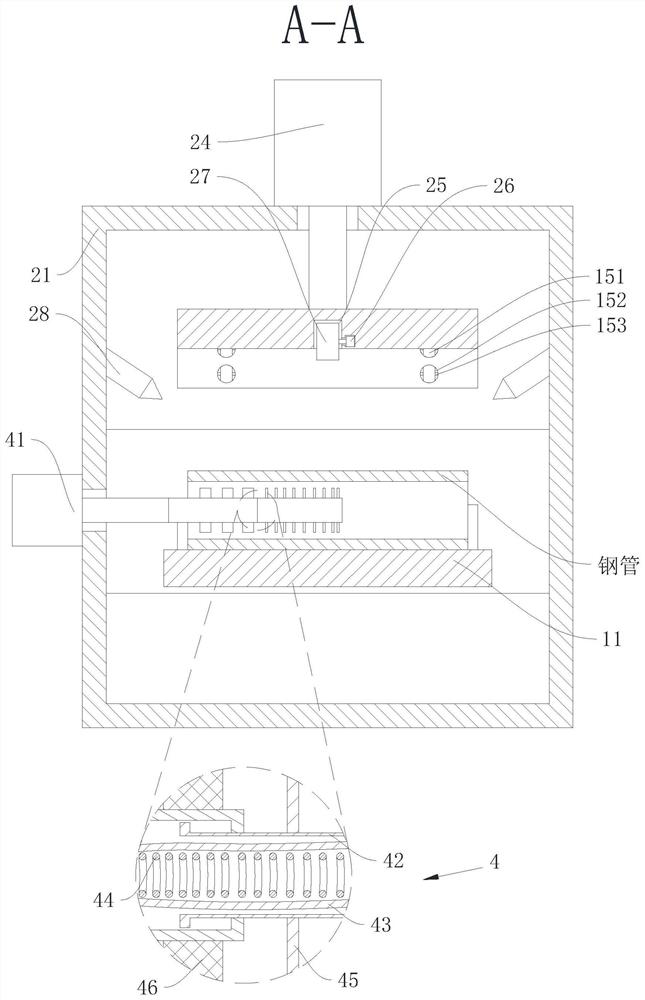

[0029] refer to figure 1 As shown, a steel pipe galvanizing processing equipment includes steel pipes to be processed, a transport device 1 for conveying steel pipes to be galvanized, a cleaning device 2 for comprehensively cleaning steel pipes, and a galvanizing device 3 for comprehensively galvanizing .

[0030] refer to figure 1 As shown, the transportation device 1 includes a chain plate conveyor belt 11, a transmission shaft 12, a mounting plate 13, a drive motor 14 and a placement block 15, the mounting plate 13 is installed on the ground in a rectangular distribution, and the transmission shaft 12 is symmetrically rotated and mounted on two opposite installations. On the inner side wall of the upper end of the plate 13, the chain plate conveyor belt 11 is installed on the outer side wall of the transmission shaft 12 and is driven by the rotation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com