Process chamber of semiconductor process equipment and semiconductor process equipment

A technology of process chamber and process equipment, applied in semiconductor/solid-state device manufacturing, metal material coating process, coating, etc., can solve problems such as pin breakage, contact state change, collision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

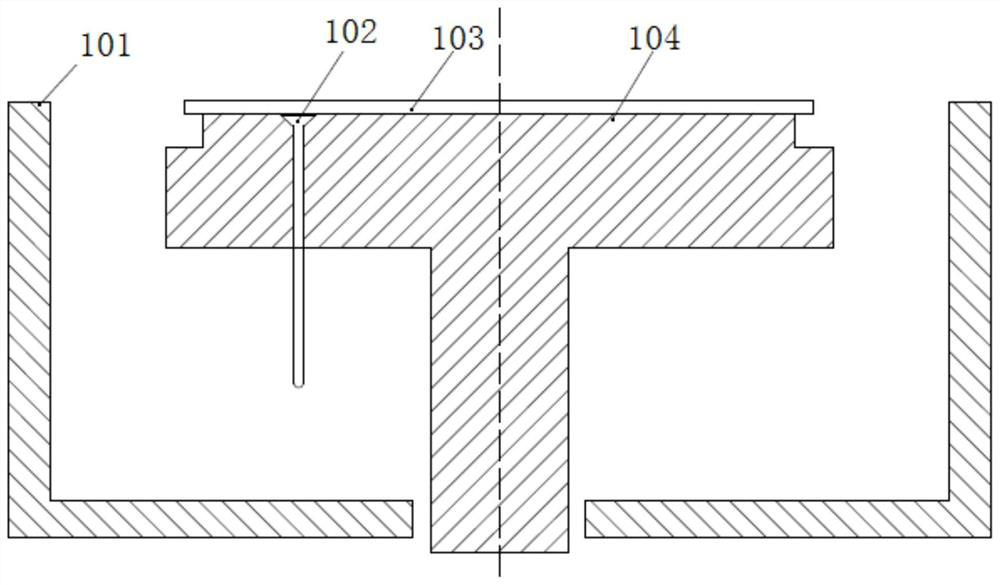

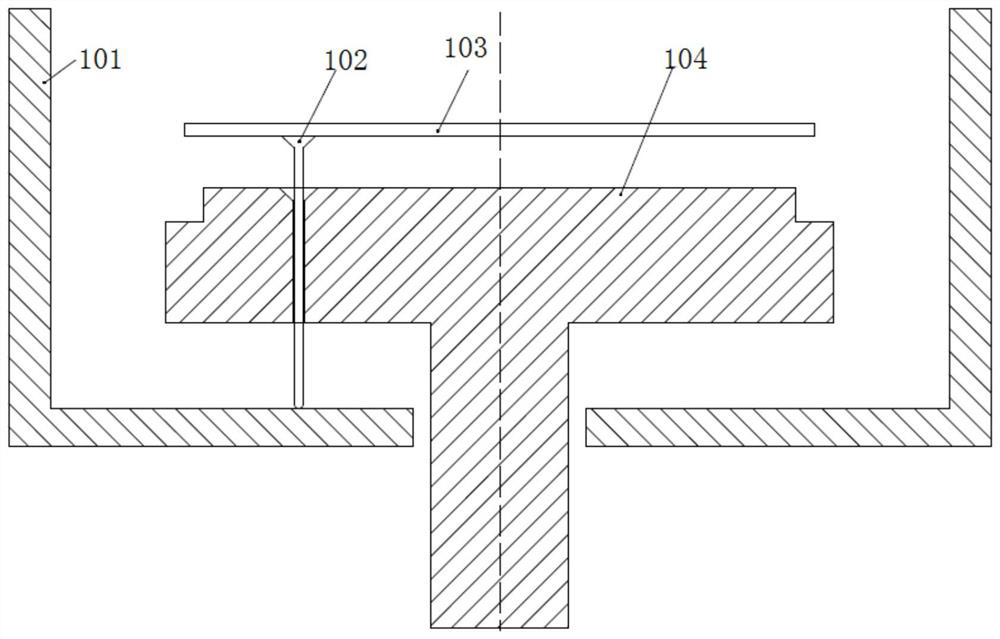

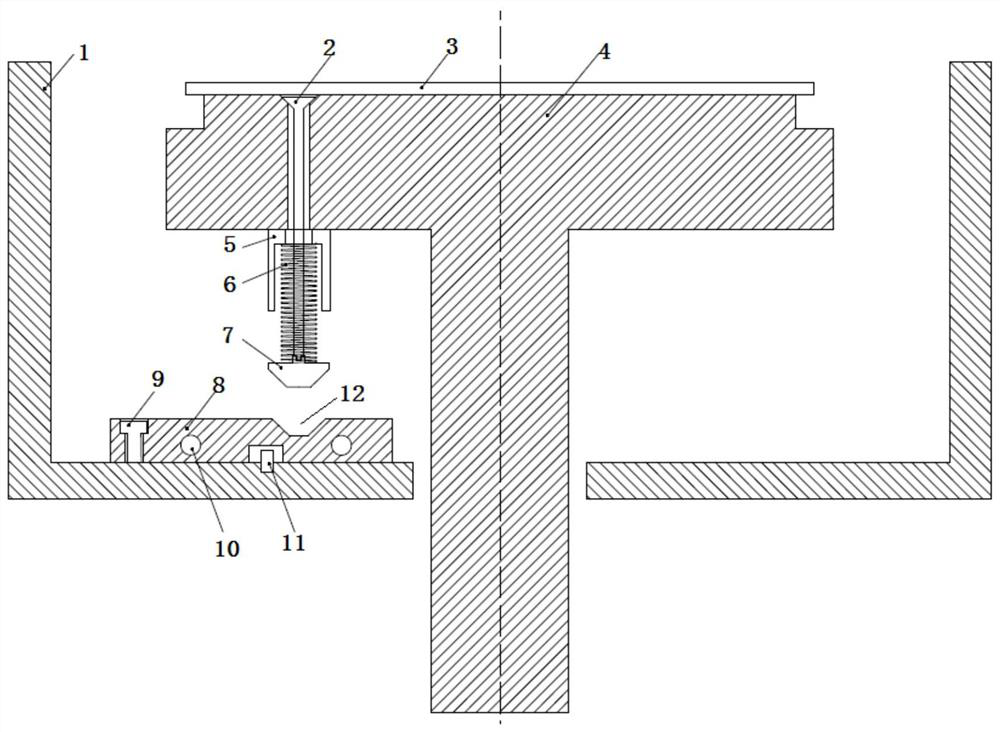

[0038] Such as figure 1 and figure 2 As shown, the existing CVD chamber includes: a chamber 101 , support pins 102 , a wafer 103 , and a base 104 . The height of the base 104 is adjusted by the lifting mechanism to realize switching between the transmission position and the process position. In the existing structure, the support needle is sealed by its own weight at the tapered surface, and there is a gap between the pinhole on the base and the support needle 102. This gap ensures that the support needle 102 slides smoothly in the hole and guides it. There is a certain inclination angle between the needle 102 and the pinhole of the base, and there is an interaction force between the support pin 102 and the side wall of the pinhole of the base. There are collisions and jams between the holes, which will cause problems such as slippage of the wafer 103, breakage of the support pins 102, and particles. The structure of the base 104 has the following problems:

[0039] 1. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com