Large-span cantilever tensile counterweight roof structure and construction method thereof

A technology of large-span cantilever and construction method, which is applied in the direction of roof, building components, building structure, etc., can solve the problems of increased steel consumption, increased cost, and easy to fall off the cantilever.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

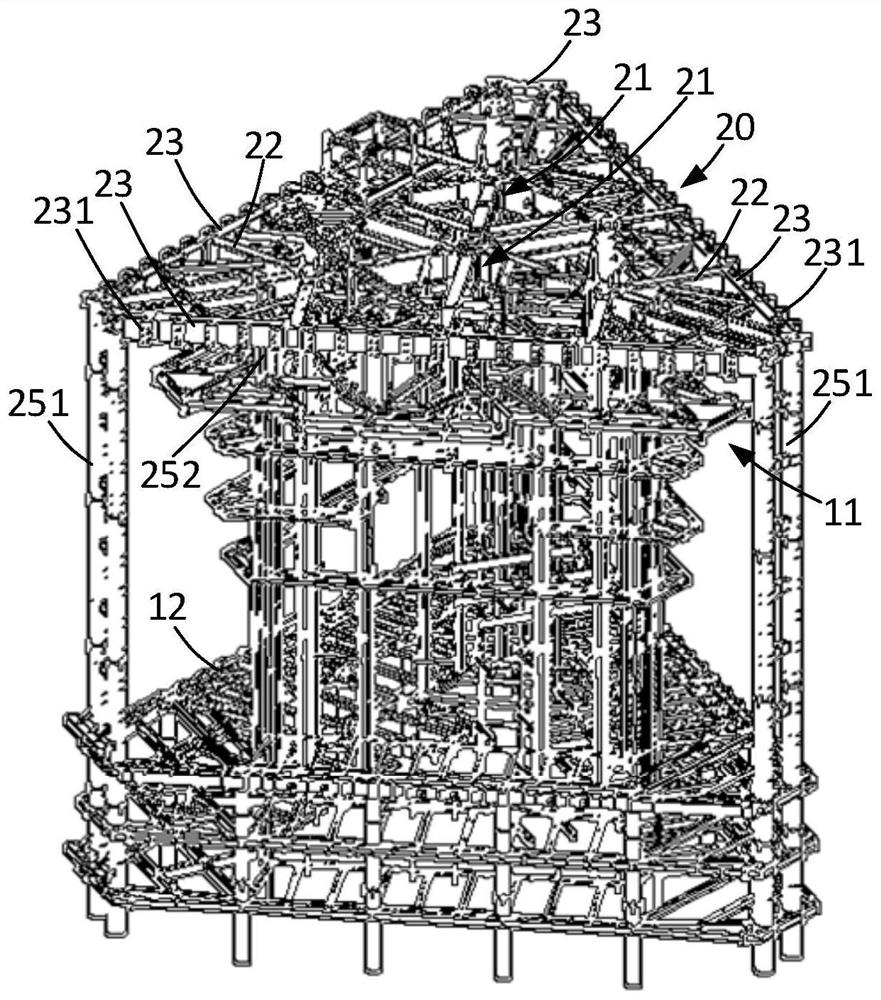

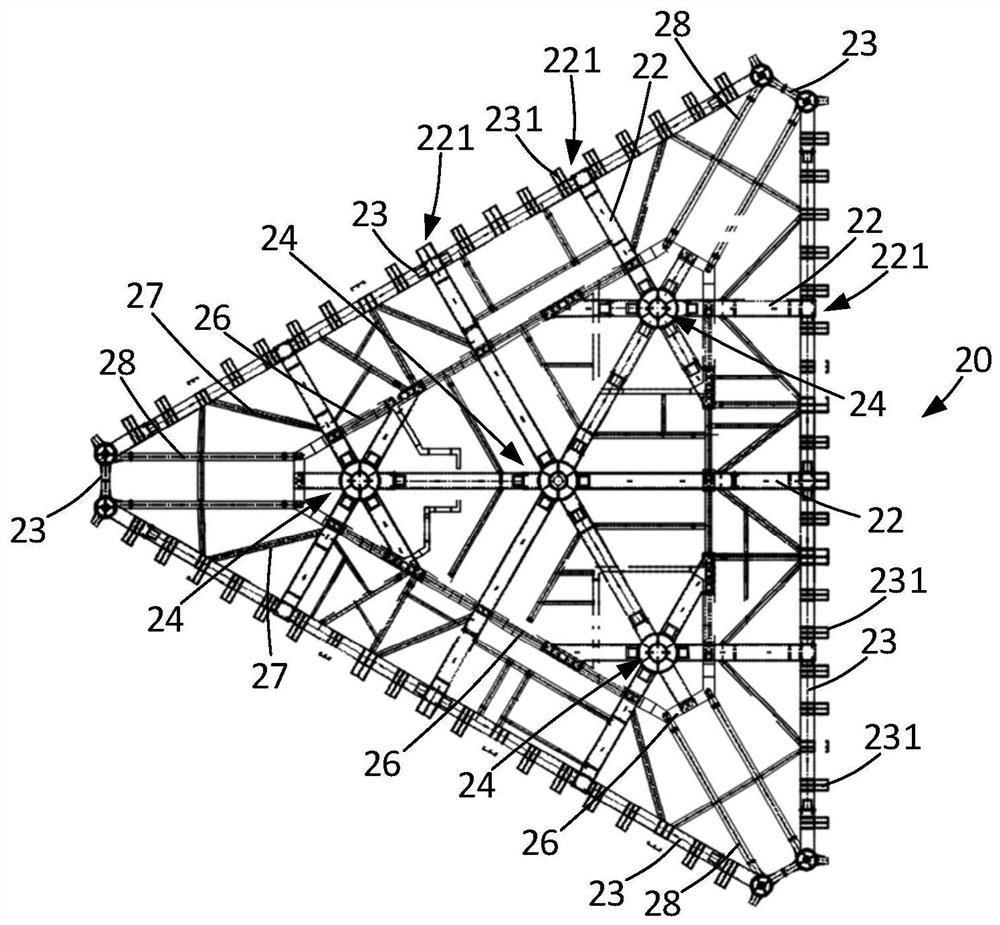

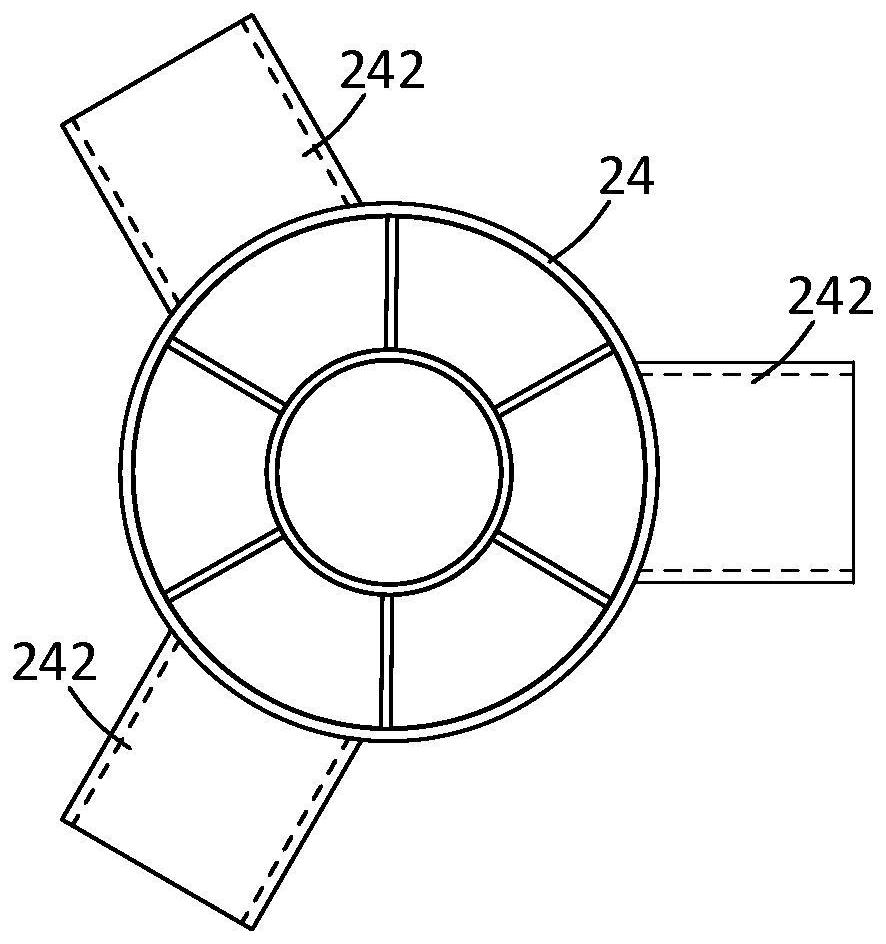

[0041] refer to figure 1 , the present invention provides a large-span cantilevered tension-resistant counterweight roof structure and its construction method. The outer periphery of the counterweight roof structure is provided with a cable, and the cable is used to form a form of tensile force transmission to realize the cable-like outside. The installation of the curtain wall structure system greatly improves the safety, and at the same time, the secondary roof layer is used as the overall counterweight, thereby reducing the amount of steel used for the roof layer and the construction energy consumption. The large-span cantilevered tension-resistant counterweight roof structure and its construction method of the present invention will be described below in conjunction with the accompanying drawings.

[0042] refer to figure 1 , shows a stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com