Test board and test method based on test board

A test method and test bench technology, applied in the field of vehicles, can solve the problems of inability to achieve compatibility, difficulty in installation and movement of the main drive motor, and the influence of the main drive motor on installation and measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be noted that although the drawings and the following description divide the present invention into multiple embodiments for description, those skilled in the art understand that, in the case of no conflict, each embodiment in the present application and the embodiment The features in can be combined with each other.

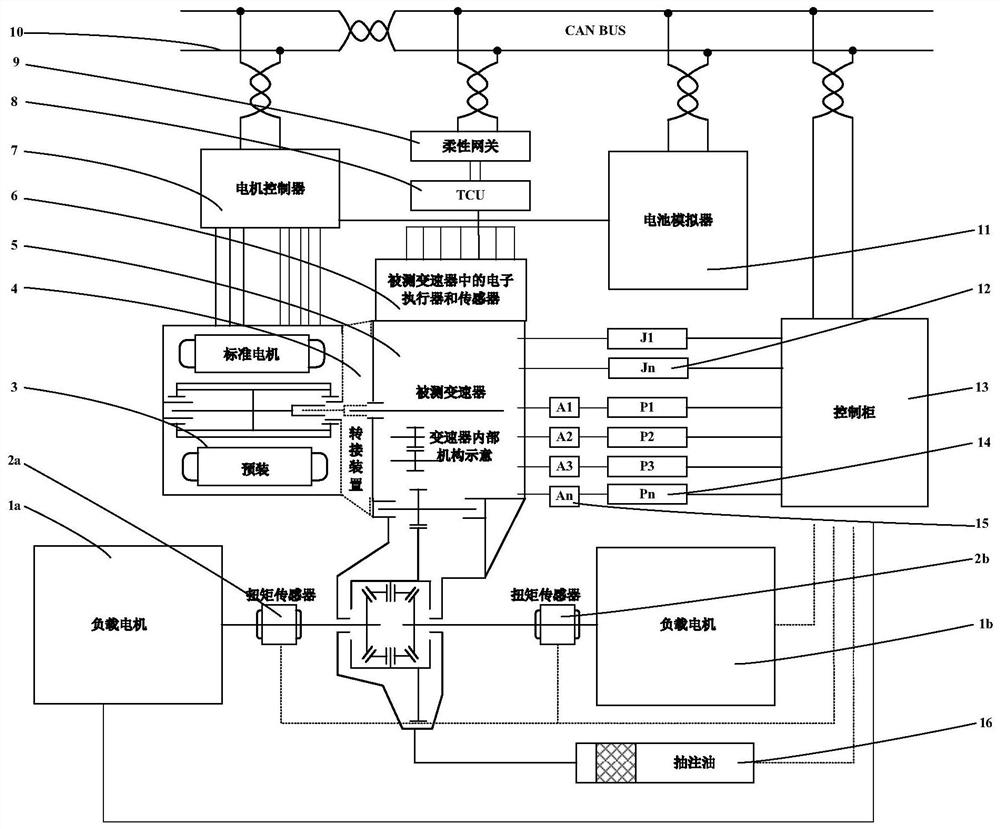

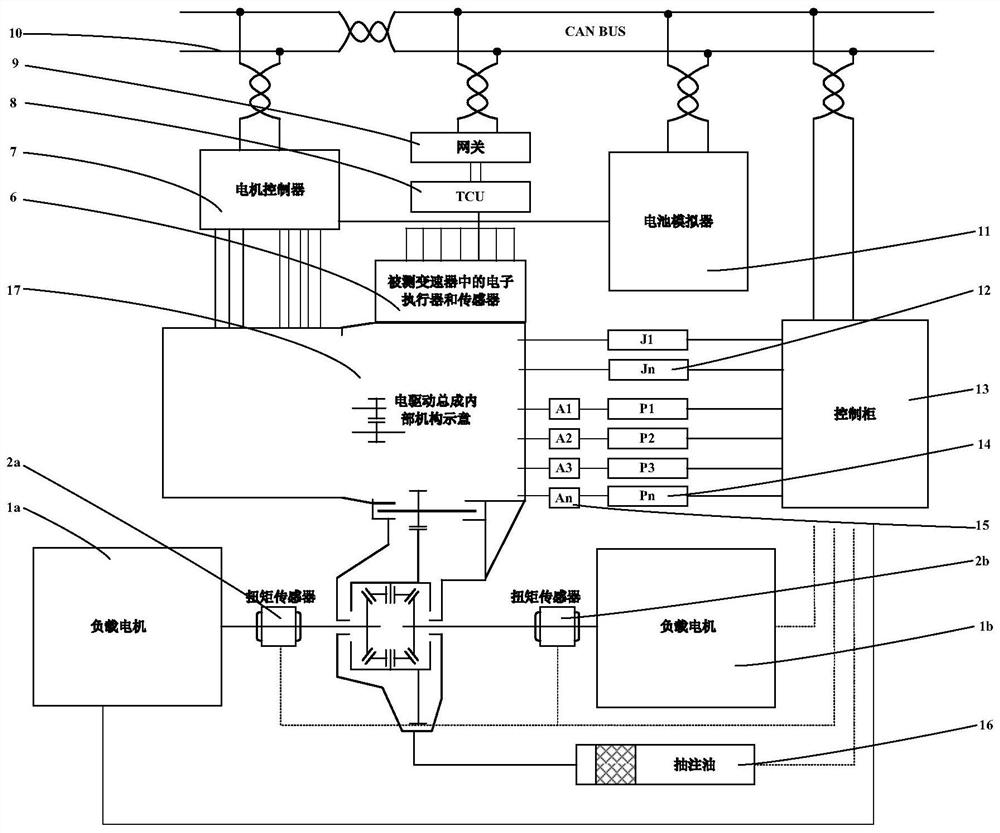

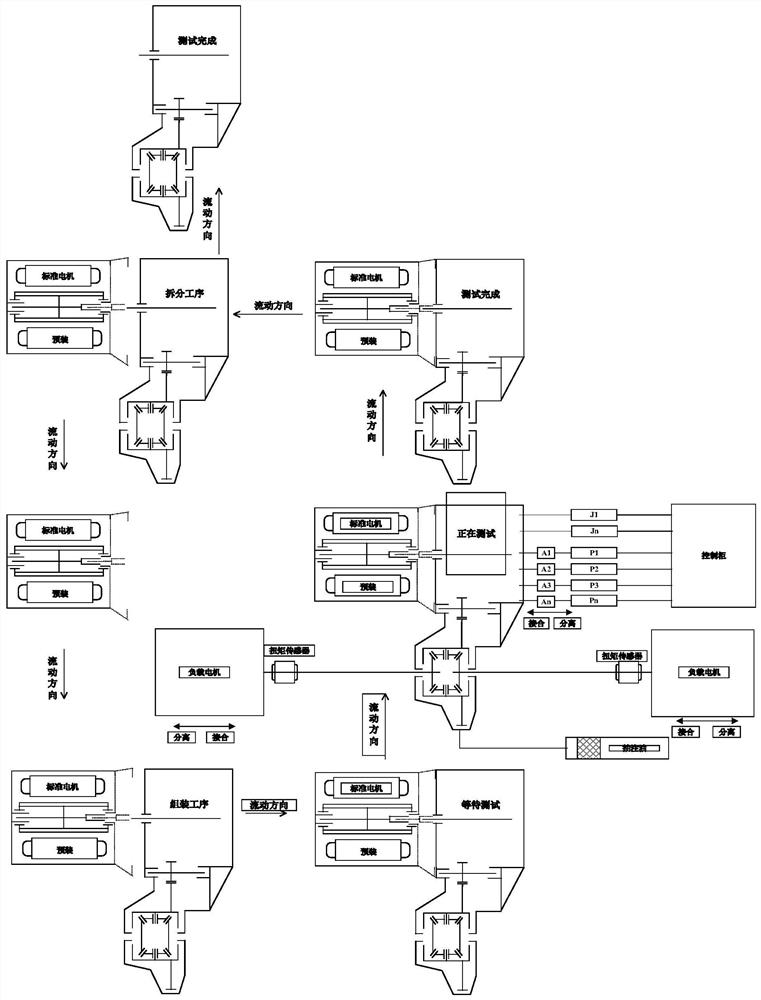

[0043] figure 1 The scheme of the end-of-line test bench equipped with an electric drive transmission is shown. exist figure 1 In the above, the electric drive transmission to be tested includes the transmission under test 5, and the transmission under test 5 includes a housing, an internal gear transmission and a differential. In addition, the tested transmission 5 also includes electronic actuators and sensors, such as solenoid valves, temperature sensors and the like. Two load motors 1a, 1b are symmetrically arranged at both ends of the two output shafts of the differential of the transmission under test 5, and these two load motors are us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com