Segmentation strengthening method for damage detection image of aerospace composite material

A composite material, damage detection technology, applied in image analysis, image enhancement, image data processing, etc., can solve the problems of large background noise, small damage defect size, and unfavorable image segmentation in infrared reconstructed images.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

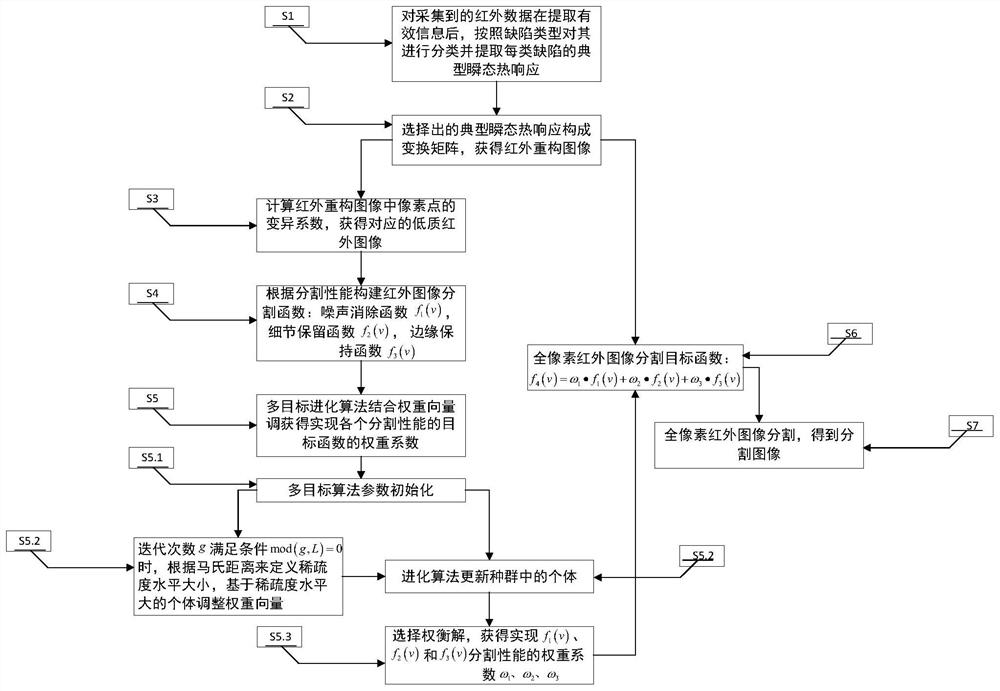

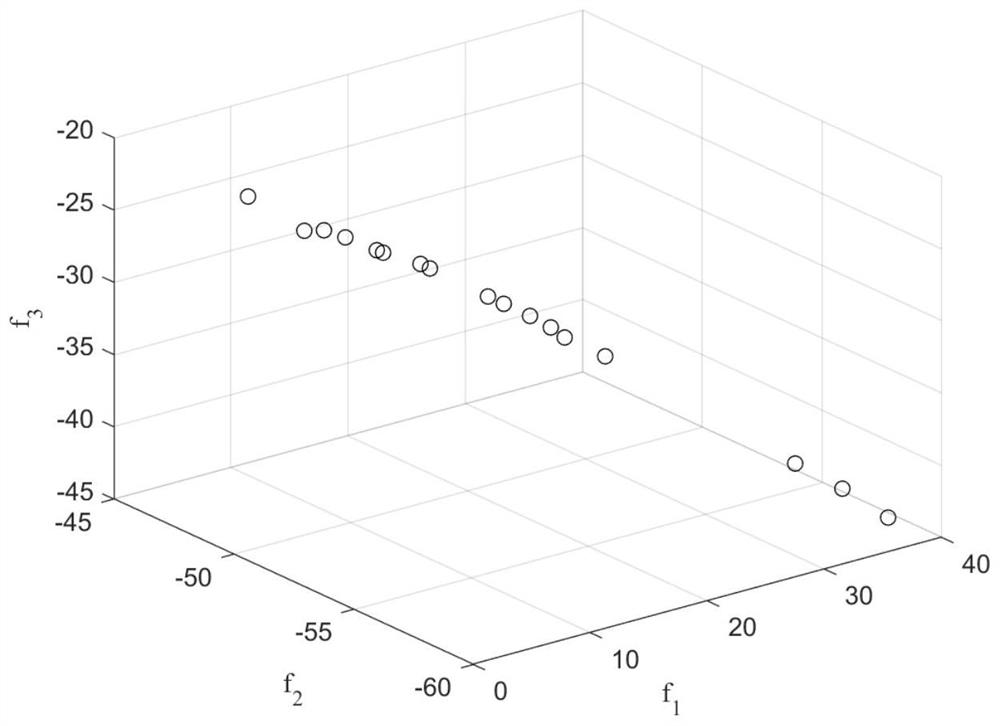

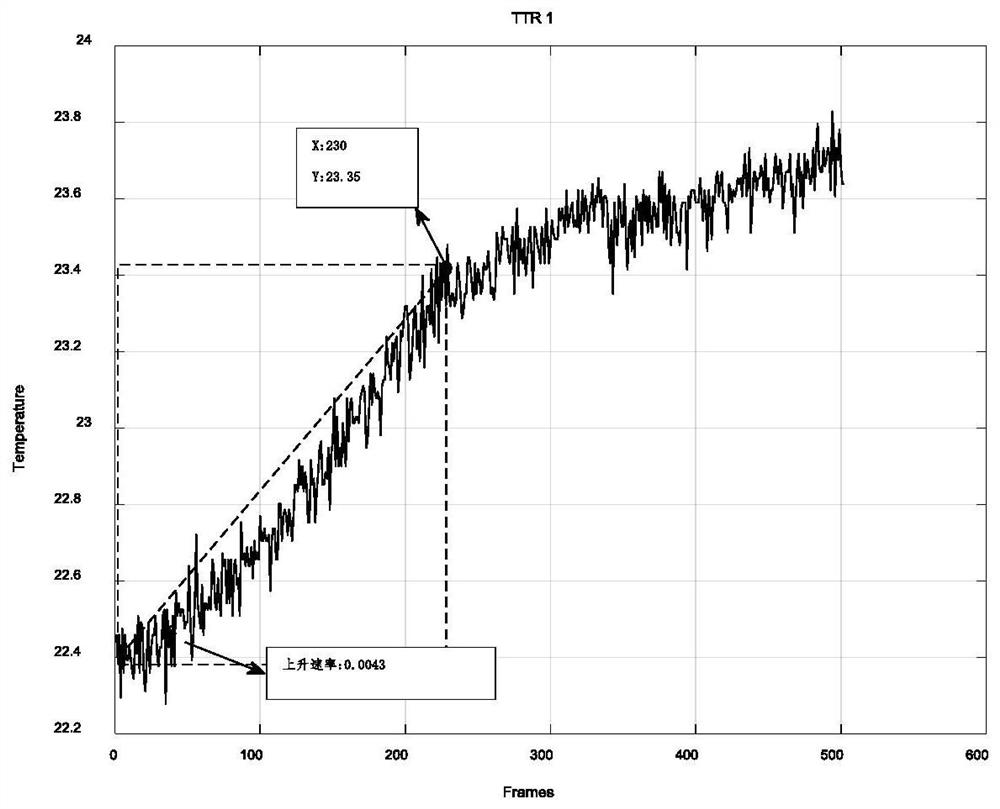

[0224] In this embodiment, the infrared thermal imaging camera collected 502 frames of images with a pixel size of 512×640. That is, there are 327,680 temperature points on each map, and the temperature value of each temperature point is recorded 502 times. This time-varying temperature condition constitutes the transient thermal response TTR of the temperature point. Step 1: After extracting the effective transient thermal response from the infrared thermal sequence, divide the area according to the defect type, and extract the typical transient thermal response from each type of divided area. When extracting the effective transient thermal response, set the parameter Re CL =0.92, 441 valid transient thermal responses containing complete defect information were extracted from 327,680 temperature points. According to the pixel points, the membership degree of each cluster center is softened, and 103, 196 and 142 thermal response curves are divided into corresponding categor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com