Preparation method of double-layer surface-coated high-nickel ternary single-crystal positive electrode material

A positive electrode material and surface coating technology, which is applied in the field of preparation of double-layer surface-coated high-nickel ternary single-crystal positive electrode materials, and can solve problems such as the negative effect of high-nickel ternary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

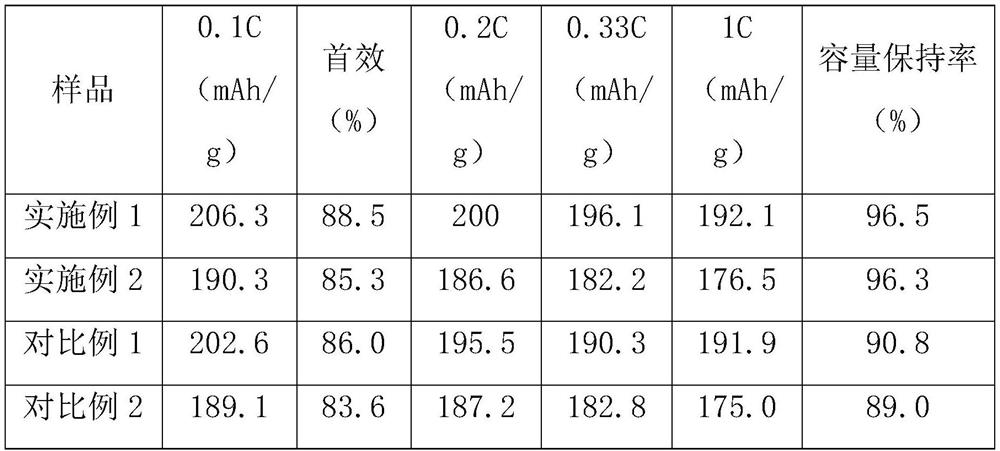

Examples

Embodiment 1

[0029] A kind of Li 1.4 Al 0.4 Ti 1.6 (PO 4 ) 3 The preparation method of / KH560 composite coated high-nickel ternary 811 single crystal positive electrode material specifically includes the following steps:

[0030] (1), weigh 3.66gLi 2 CO 3 , 2.04g of aluminum hydroxide and 26.32g of ammonium dihydrogen phosphate were added to 5000g of NCM811 single crystal positive electrode material, mixed for 1 hour using a ball mill jar and a polyurethane ball mill, the ball milling speed was 120r / min, and mixture A was obtained after ball milling;

[0031] (2) Weighing 36.00 g of tetrabutyl titanate and adding it to mixture A, maintaining the ball milling conditions in step (1) (ball milling and mixing for 1 h, ball milling speed of 120 r / min) for ball milling and mixing, and mixture B was obtained after ball milling and mixing;

[0032] (3), the mixture B in O 2 Under the atmosphere, the Li 1.4 Al 0.4 Ti 1.6 (PO 4 ) 3 Coated high-nickel ternary 811 single crystal cathode ma...

Embodiment 2

[0038] A kind of Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 The preparation method of / KH570 composite coated high-nickel ternary 712 single crystal positive electrode material specifically includes the following steps:

[0039] (1) Weigh 3.40gLi 2 CO 3 , 1.53g of aluminum hydroxide and 26.32g of ammonium dihydrogen phosphate were added to 5000g of NCM712 single crystal positive electrode material, mixed for 1 hour using a ball mill jar and a polyurethane ball mill, the ball milling speed was 120r / min, and mixture A was obtained after ball milling;

[0040] (2) Weigh 38.25 g of tetrabutyl titanate and add it to the mixture A, keep the ball milling conditions in step (1) (ball milling and mixing for 1 hour, and the ball milling speed is 120 r / min) for ball milling and mixing, and the mixture B is obtained after ball milling and mixing;

[0041] (3), the mixture B in O 2 Under the atmosphere, the Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Coated high-nickel ternary 712 single crystal cathod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com