Thermal management system of fuel cell engine

A thermal management system, fuel cell stack technology, applied in the field of thermal management systems, can solve the problem of cold start performance needs to be improved or enhanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]In order to understand the technical solutions of the present invention more apparent to those skilled in the art, the following examples will be described. It should be noted that the following examples do not constitute a limitation of the scope of the invention.

[0029]In an embodiment, the first, second is described, and the second is only for the purpose of distinguishing the technical feature, and cannot be understood as an indication of the technical features indicated or implicitly indicated by the indicated technical features indicated. The relationship between the characteristics.

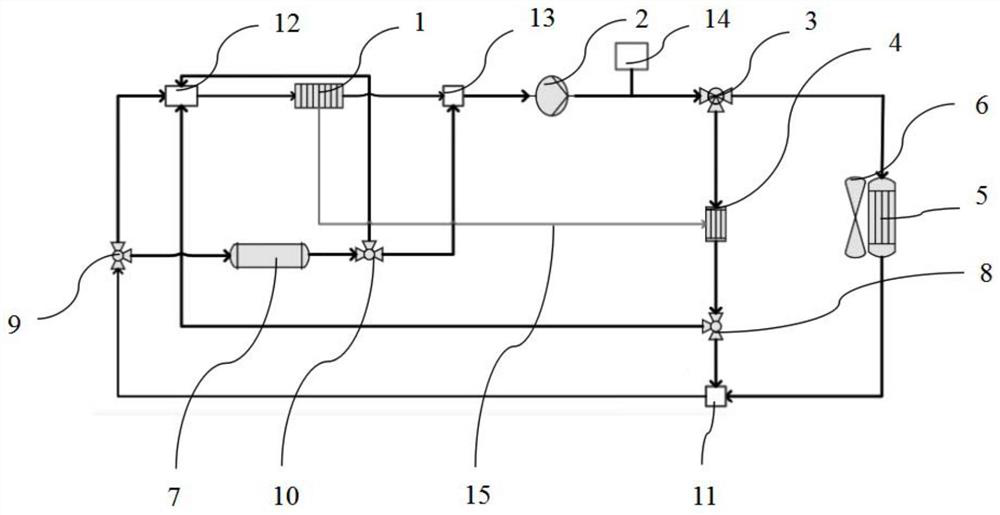

[0030]Some embodiments of the thermal management system provided in accordance with the present inventionfigure 1As shown, the thermal management system includes:

[0031]Fuel battery electric pile 1;

[0032]The thermostat 3 is connected to the fuel cell stack 1;

[0033]The PTC heating circuit includes a PTC heater 4 and a first split valve 8 in which it is sequentially connected; the PTC heater 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com