Spiral peeling device

A screw type, nut technology, applied in cable installation devices, cable installation, equipment for dismantling/armored cables, etc., can solve the problems of increasing unsafe factors, difficult peeling, and complicated adjustment work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

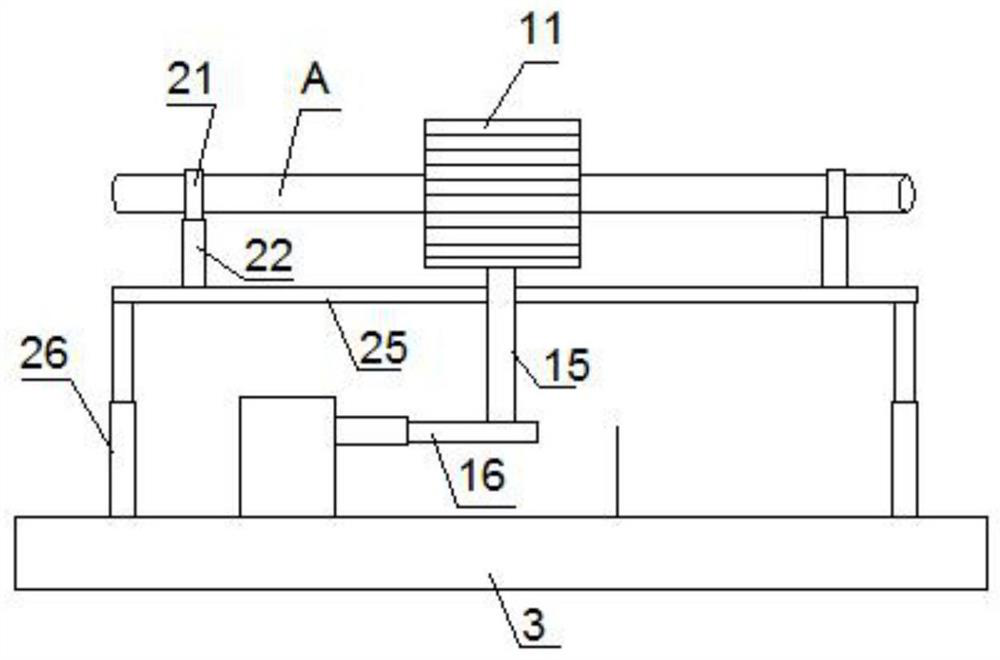

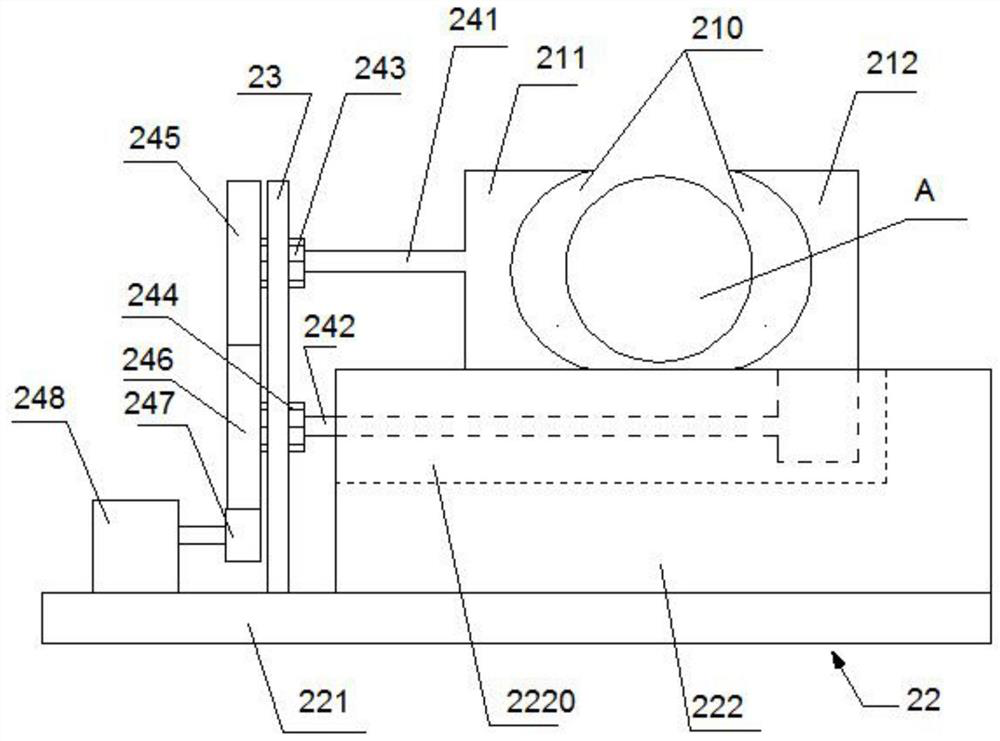

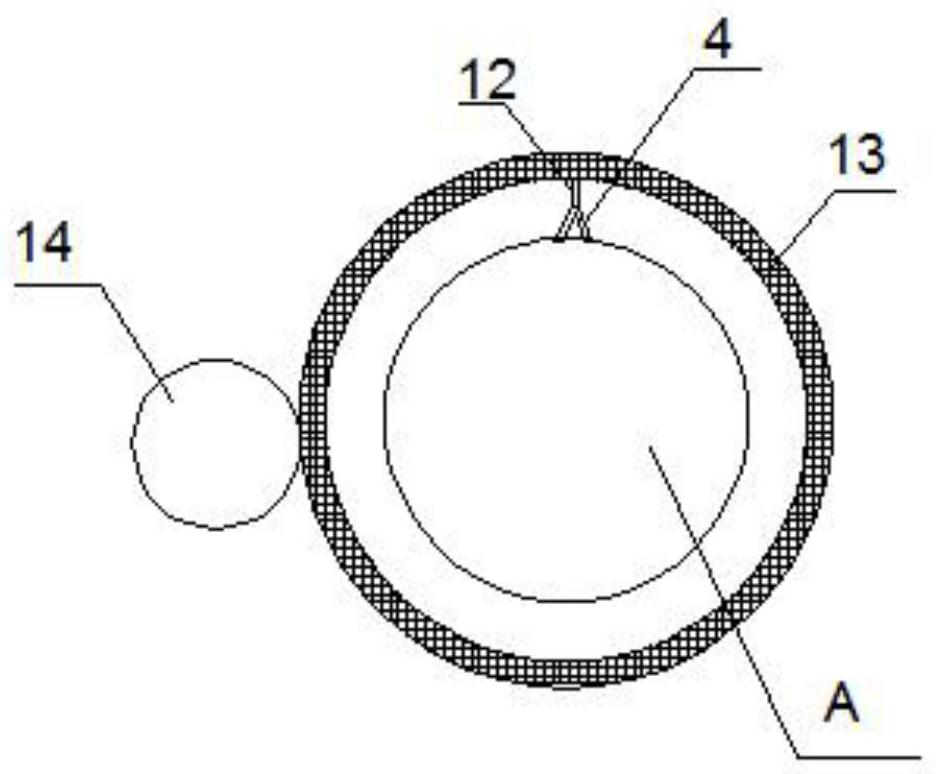

[0030] A spiral peeling device proposed in this embodiment includes: a tool support part, a cable clamping part and a base 3 . The tool supporting part is arranged on the base 3 so as to move linearly, and the cable clamping part includes two clamping executing parts respectively arranged at both ends of the moving track of the tool supporting part. The cutter supporting part is used for connecting the cutter 4 and driving the cutter 4 to move on a circular track coaxial with the cable A clamped by the cable clamping part. In this way, when working, install the tool 4 on the tool support part, then pass the cable A through the circle where the motion track of the tool 4 is located, and fix the two ends of the cable A on the two clamping execution parts respectively; then drive The cutter 4 moves in a circle and drives the cutter support part to move linearly on the base 3, so as to realize the helical cutting of the cable A skin by the cutter 4.

[0031] The cable clamping pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com